Insulating oil heating system and method for transformer fire extinguishing true form test

A heating system and insulating oil technology, which is applied in the field of transformer fire extinguishing real test insulating oil uniform heating system, can solve the problems of large differences in fire extinguishing characteristics of insulating oil, difficulty in accurately simulating real working conditions, and hindering heat conduction of insulating oil, etc., to achieve Improve the accuracy, improve the research level, and test the effect of strong economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

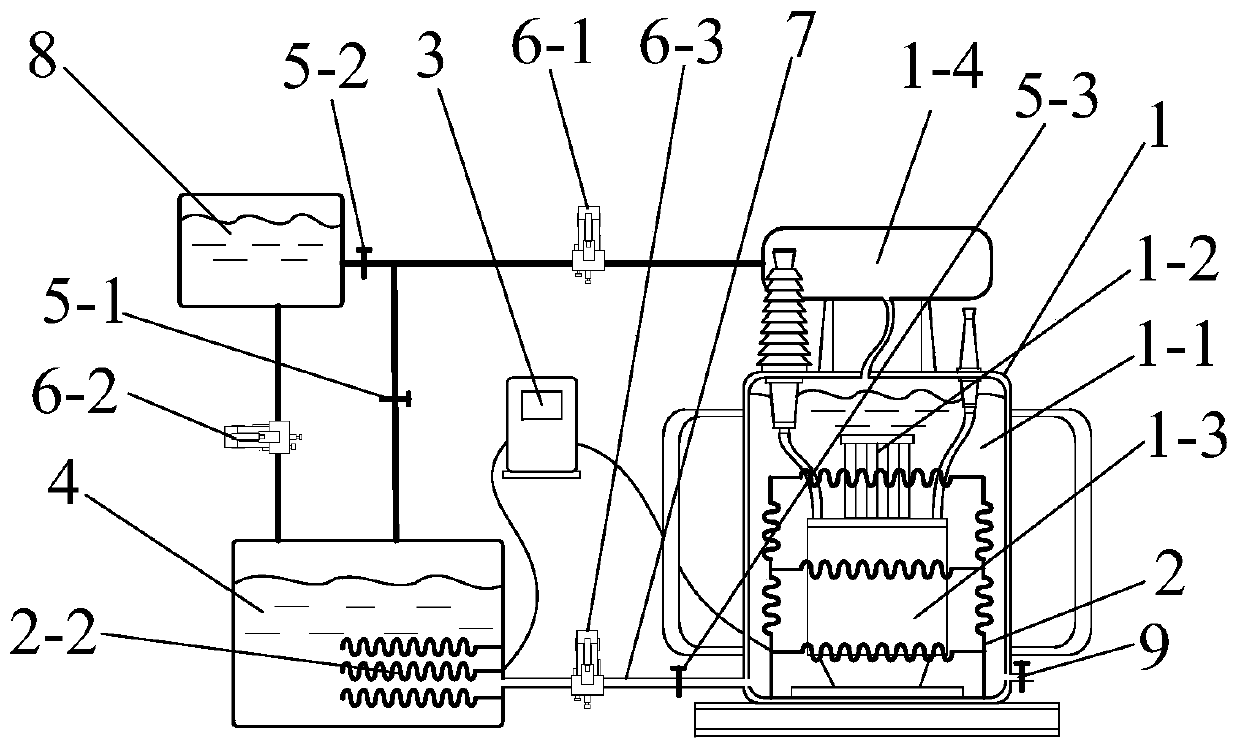

[0027] Such as figure 1 and figure 2 As shown, an embodiment of a uniform heating system for insulating oil in a transformer fire extinguishing real-type test of the present invention includes a uniform heating / constant temperature device, a preheating device, an oil replenishing device, and a heating control module 3; the heating control module 3 is used for uniform heating / The constant temperature device and the preheating device provide the power supply and control the heating power.

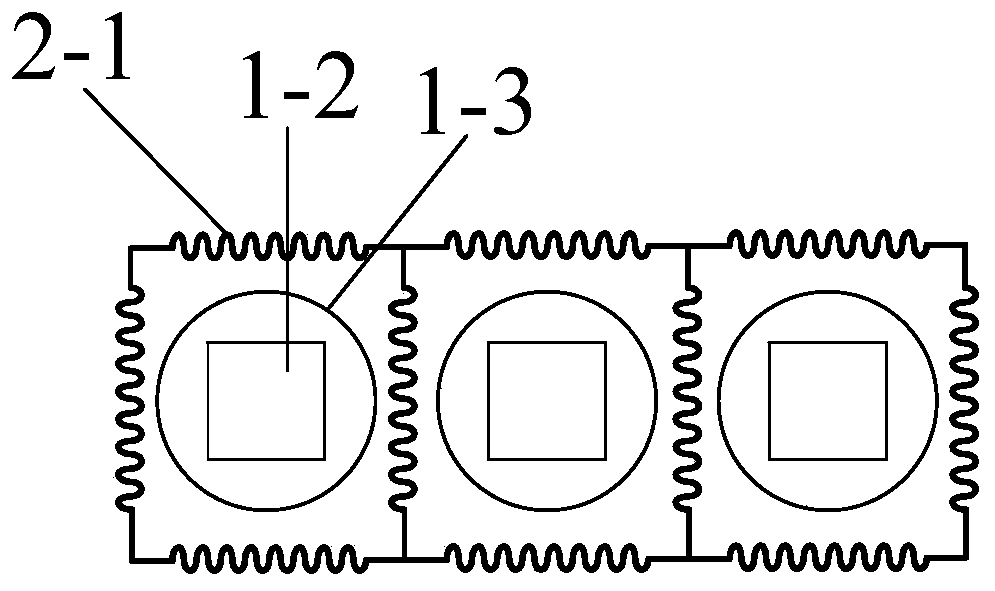

[0028] In this embodiment, the uniform heating / constant temperature device is used to evenly heat the insulating oil in the oil tank 1-1 of the real-type test transformer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com