Air filter self-cleaning control method and air filter self-cleaning control device

An air filter and control method technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problem of stopping dusty air and achieve the effect of increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

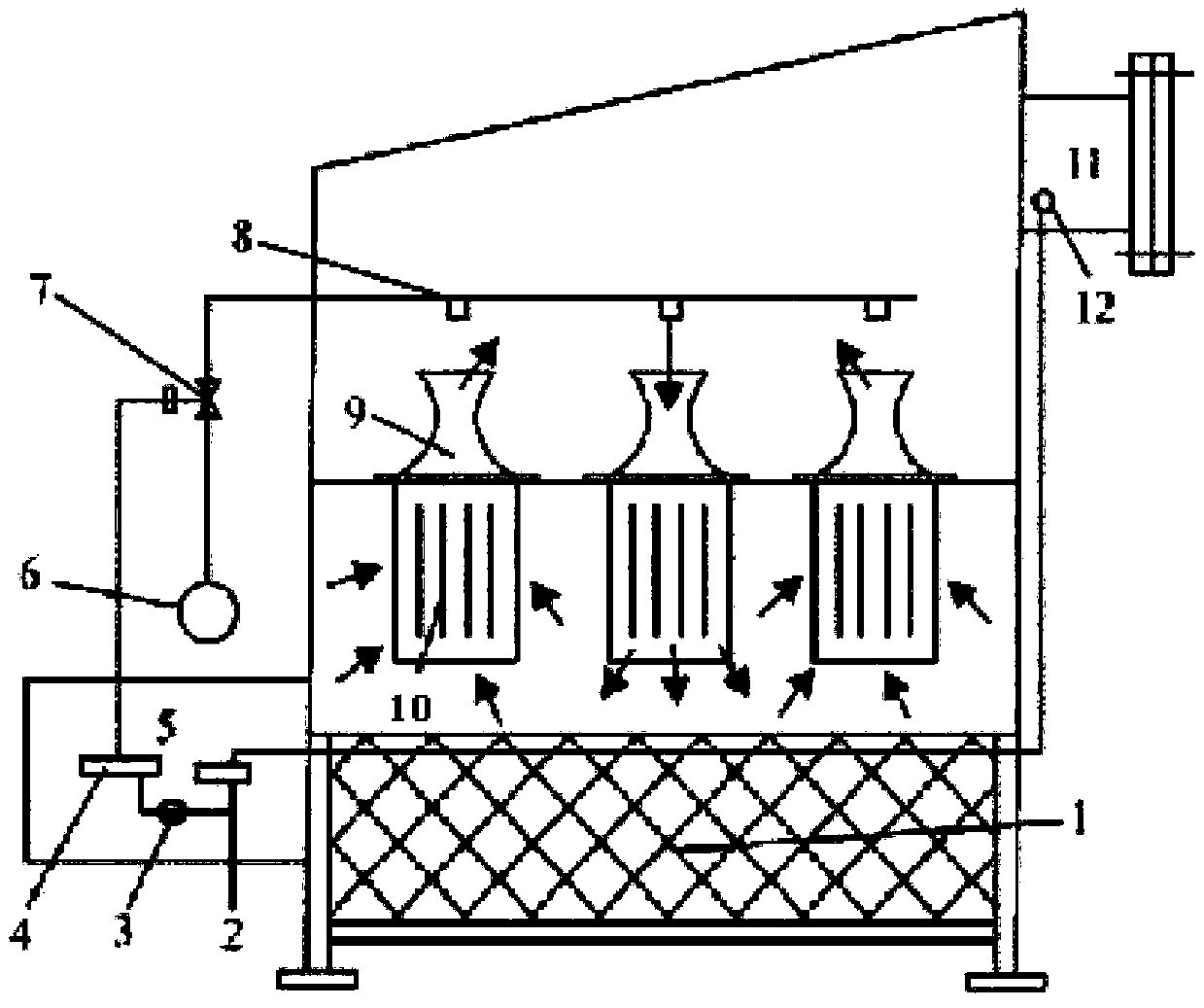

[0061] In order to solve the problem that the filtering of dusty air must be terminated during the process of cleaning the filter cartridge, the present application provides an air filter self-cleaning control method and device.

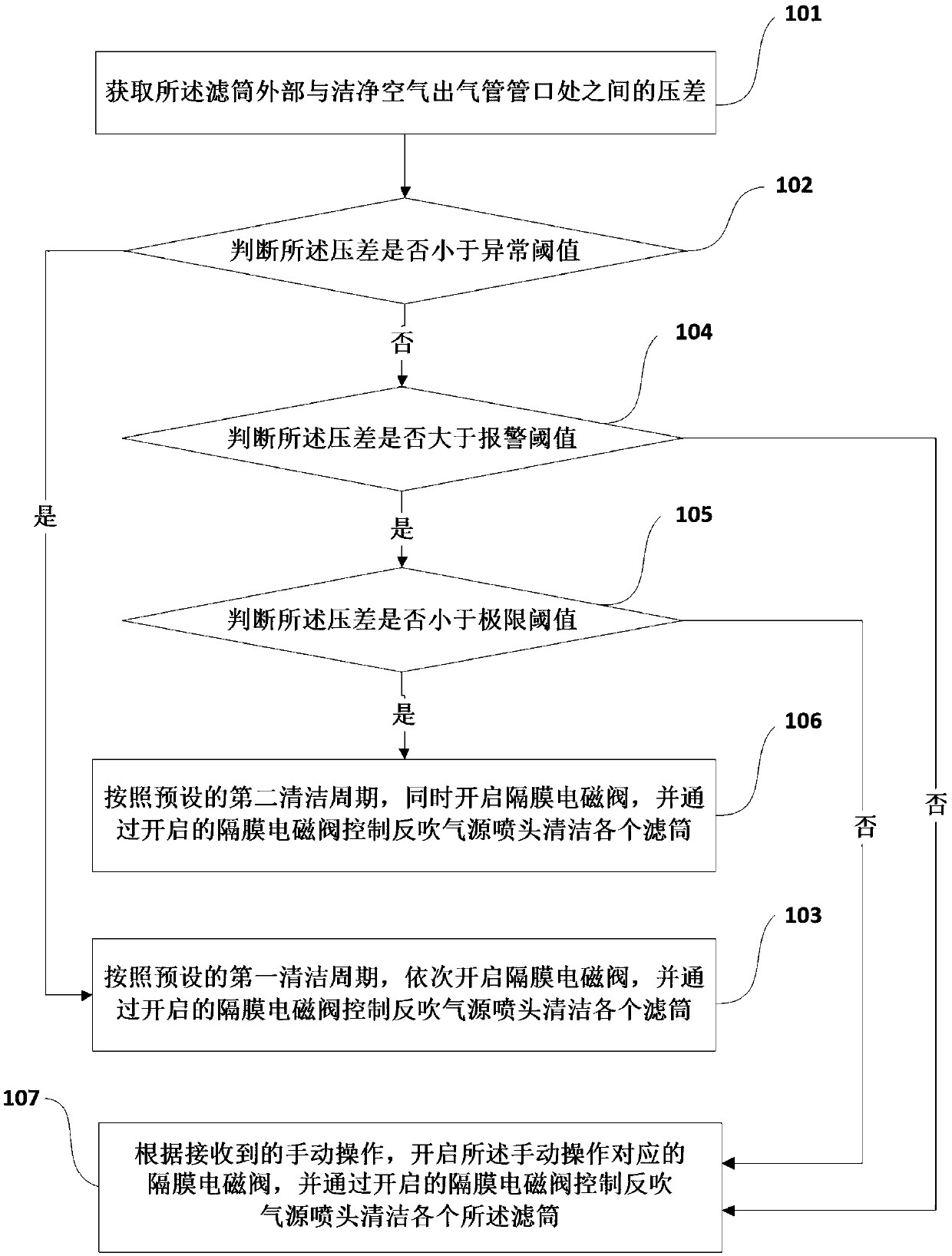

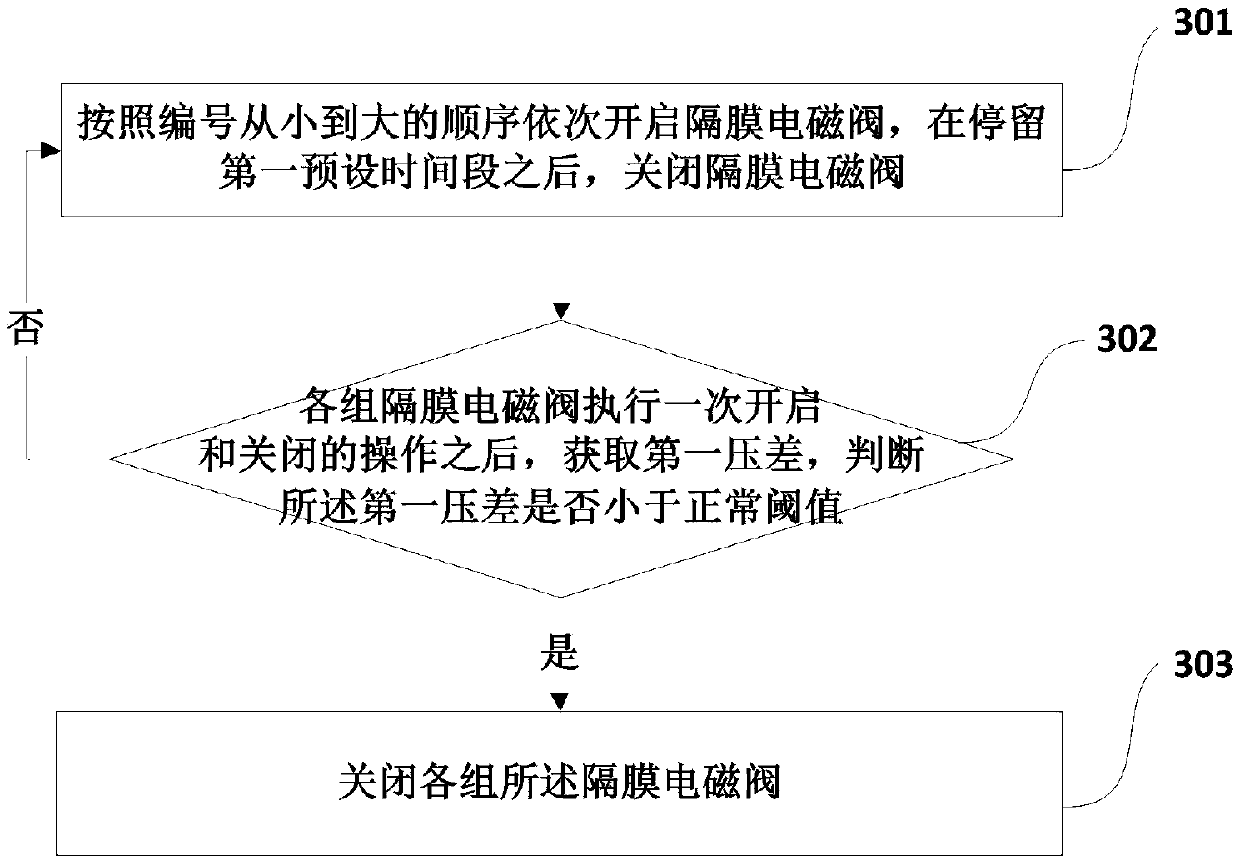

[0062] In the current technology, the PLC automatic control unit and the air filter are packaged together, and the differential pressure controller is used to measure the pressure difference between the outside of the filter cartridge and the mouth of the clean air outlet pipe, and the differential pressure controller transmits the differential pressure signal to the PLC automatic control unit , the PLC automatic control unit determines whether to filter the filter cartridge according to the range of the pressure difference. Due to the fixed program set in the PLC automatic control unit, the existing self-cleaning air filter can only clean the filter cartridge according to the fixed program set by the PLC automatic control unit. However, the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com