Steel pipe nozzle circle calibration mechanism

A nozzle and rounding technology, used in safety equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complicated centering methods, affecting the overall quality of products, and low overall production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

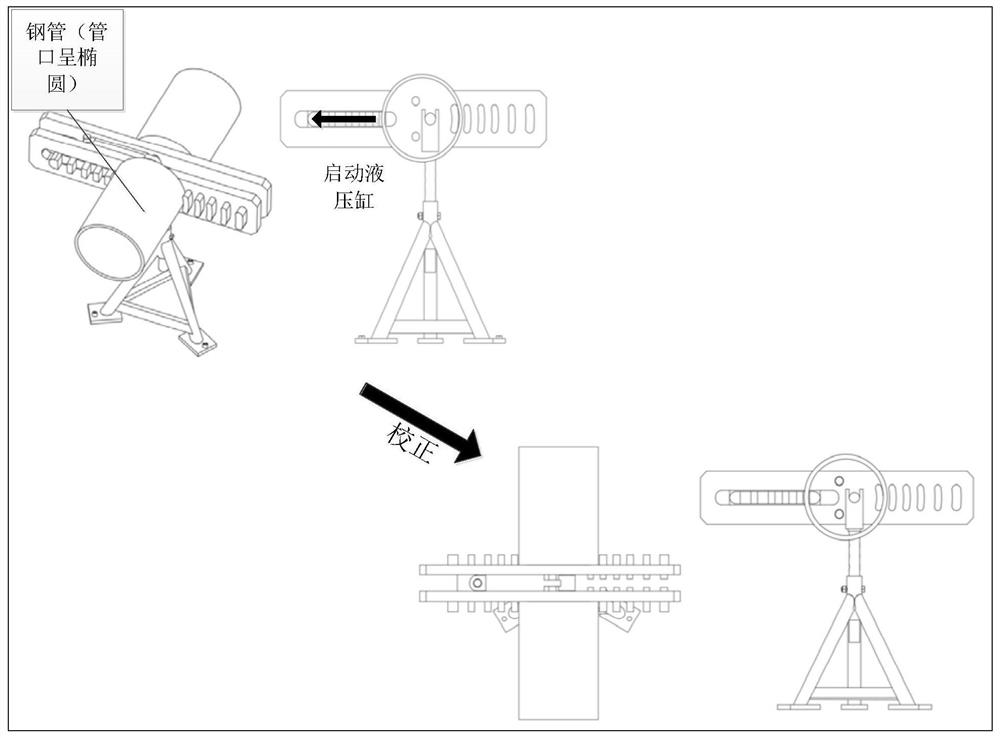

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

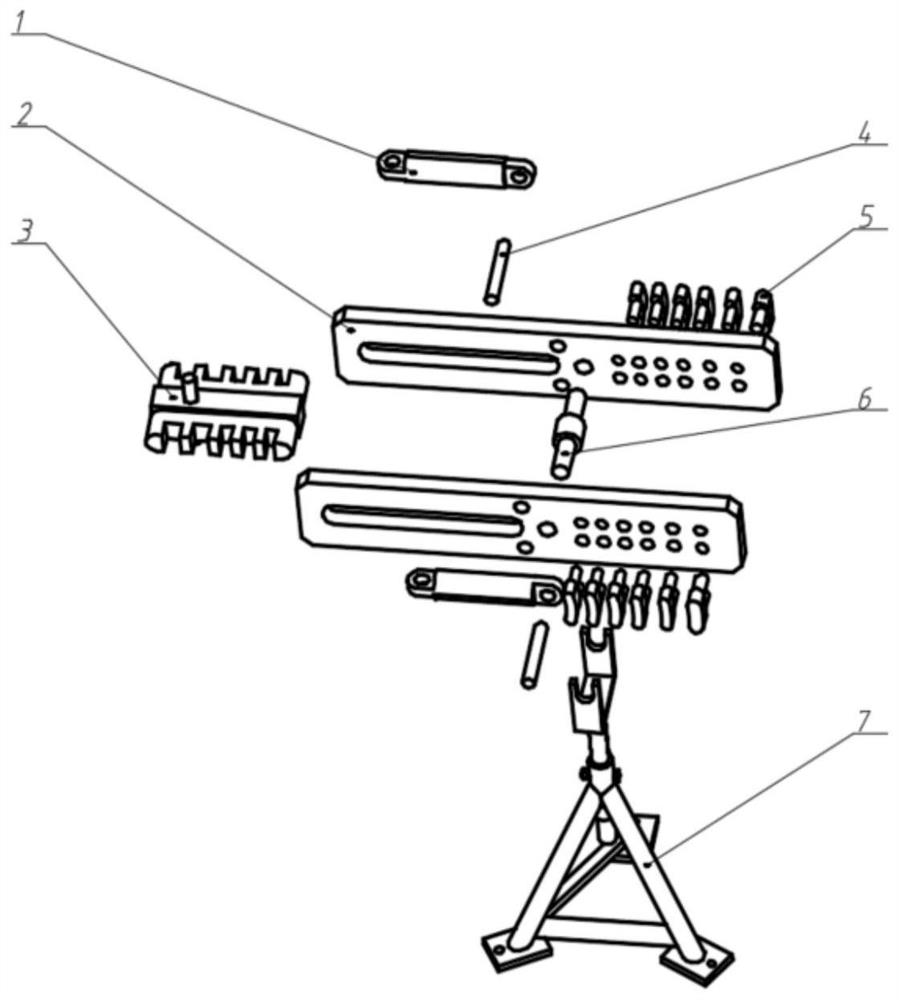

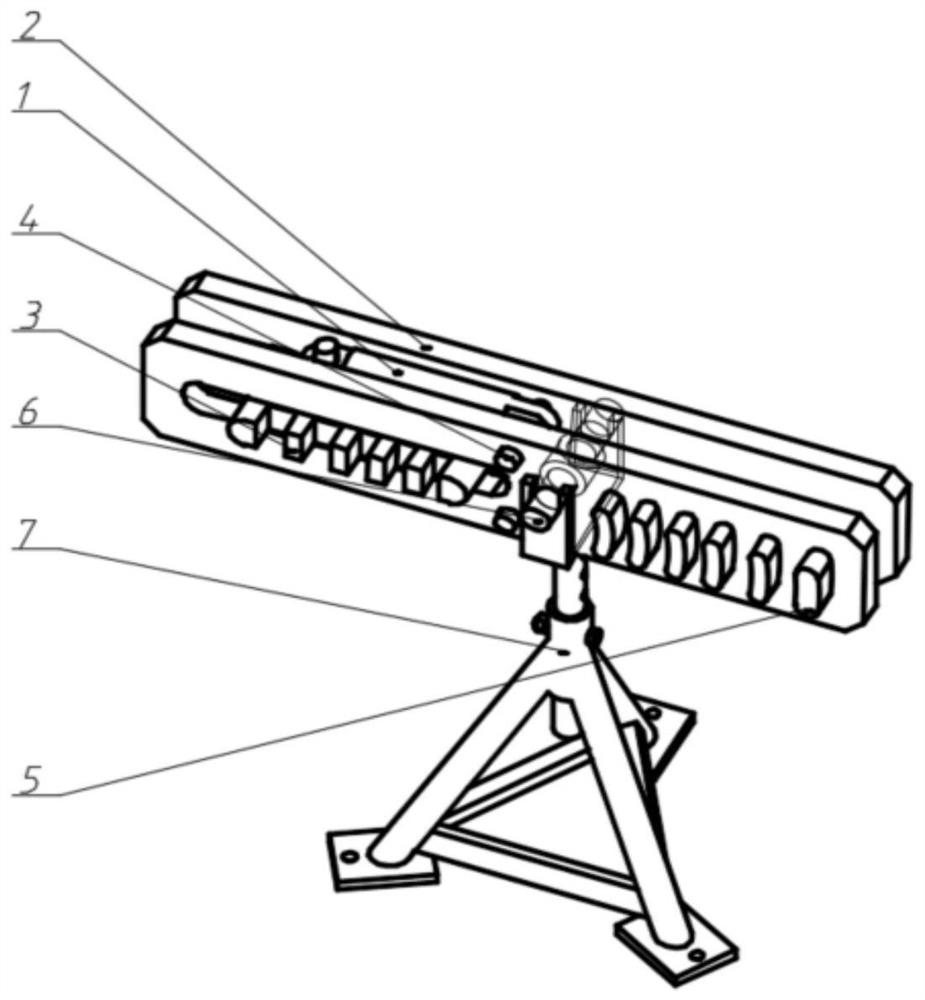

[0022] The rounding mechanism of the steel pipe nozzle of the present invention comprises two main plates, two hydraulic cylinders with linear displacement sensors, one mandrel, two pin shafts, six pairs of clamping blocks, one limit slider, and one supporting base; A total of six pairs of clamping blocks are arranged, the distance between the clamping blocks is 30mm~60mm, the diameter of the butt steel pipe and the corresponding pipe wall thickness: 355mm (10~20mm), 406 (13~20mm), 508mm (13~25mm), 610mm (13 ~ 25mm), 762mm (16 ~ 38mm), 914mm (40mm), the ellipticity is less than 1% of its nominal diameter and the maximum is not more than 5mm.

[0023] The limit slider is placed in the main body plate, and the left and right sides are symmetrical. There are six bosses respectively corresponding to the six blocks. Two connecting columns ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com