An industrial robot for pipe welding and its control method

An industrial robot and pipeline technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the inner wall of the pipeline is easy to slip, difficult to maintain stability, unable to move, etc., to achieve strong passability and improve passability , The effect of strong obstacle avoidance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

[0032] According to an embodiment of the present invention, an industrial robot for welding pipelines and a control method thereof are provided.

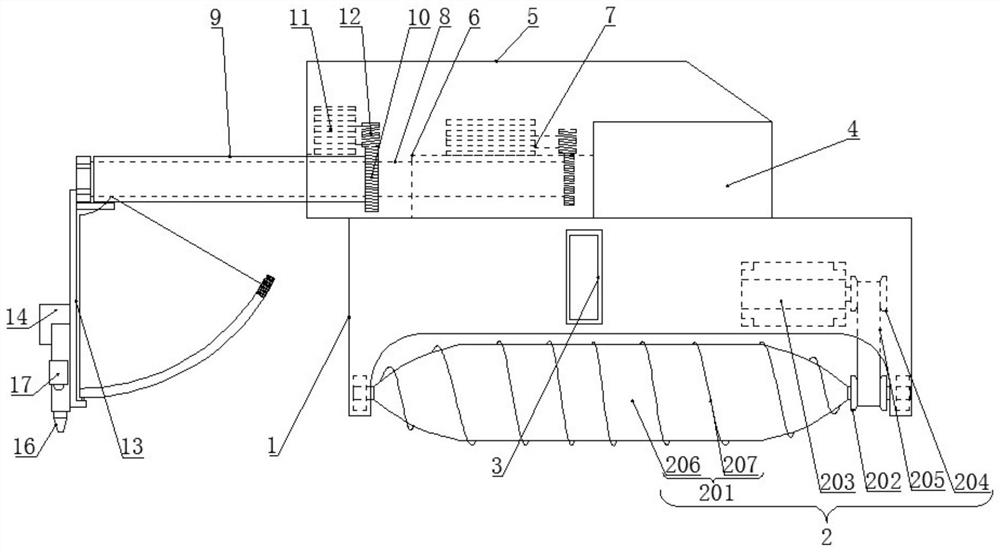

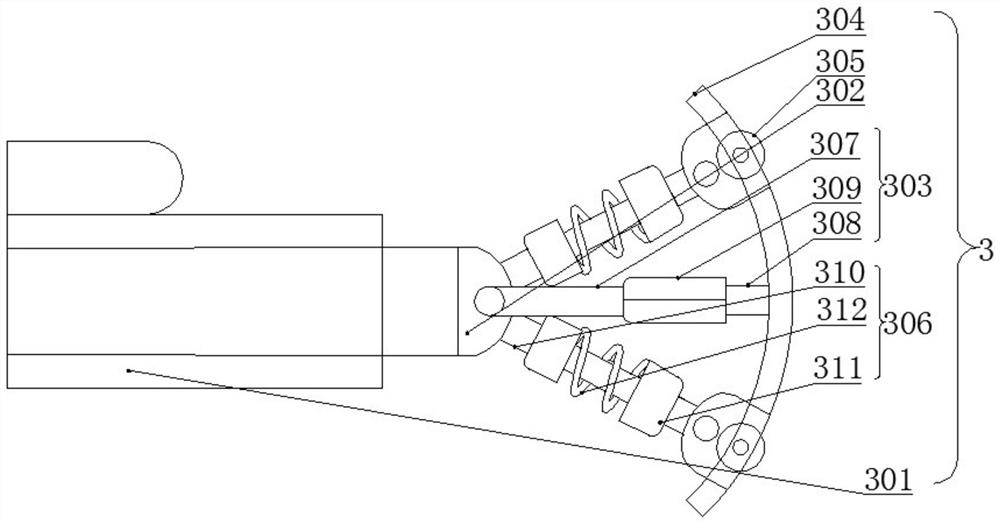

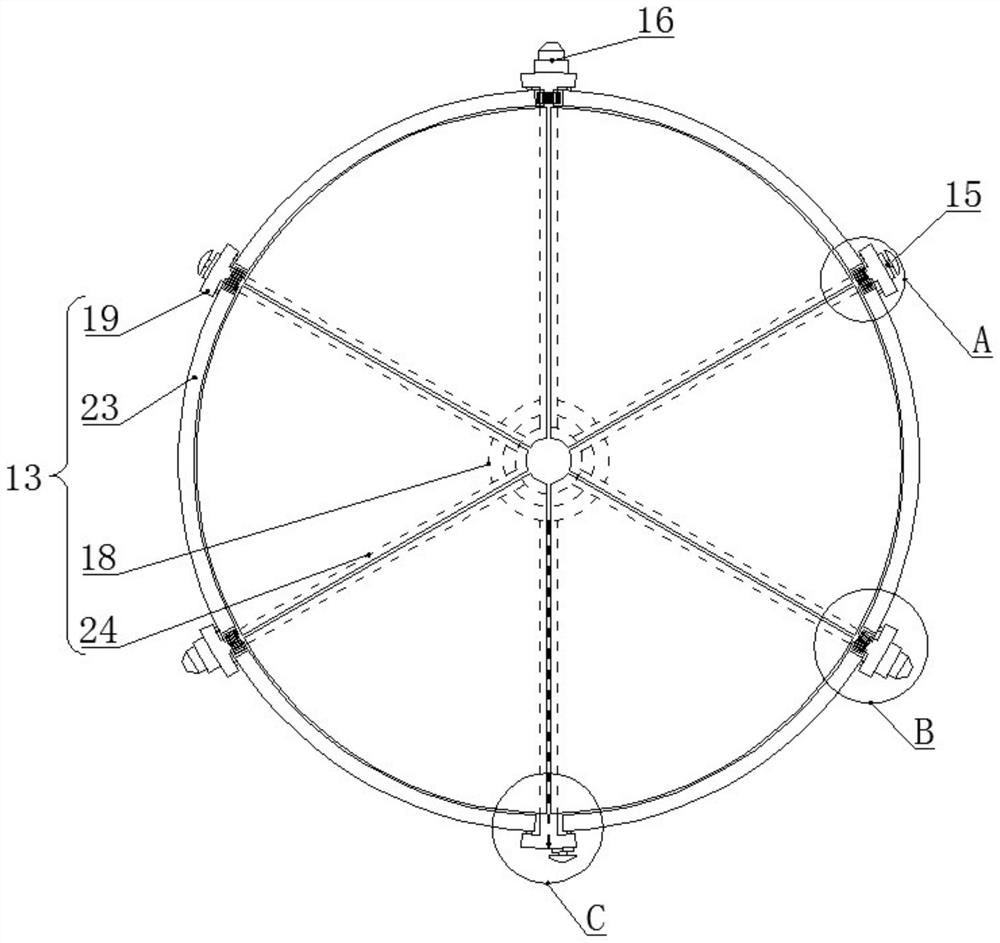

[0033] Such as Figure 1-8As shown, the industrial robot for pipeline welding according to the embodiment of the present invention includes a car body 1, the bottom of the car body 1 is provided with a traveling mechanism 2, and the side of the car body 1 is symmetrically provided with a lateral support mechanism 3, and the lateral support Mechanism 3 is arranged symmetrically on both sides of the vehicle body, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com