Cutting fluid recovery device used for numerically-controlled machine tool

A recycling device, CNC machine tool technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as troublesome, difficult cleaning, cutting droplets falling on clothes or the ground, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

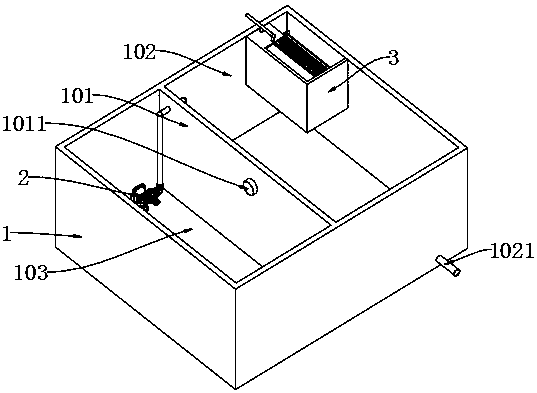

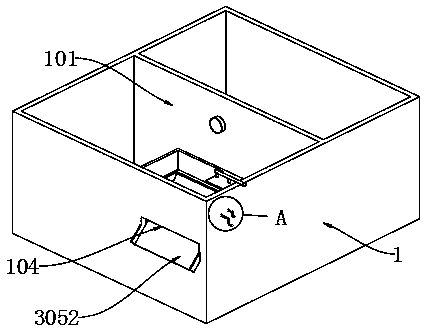

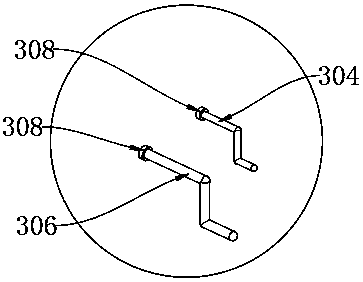

[0033] As attached figure 1 Attached Picture 9 Shown:

[0034] The present invention provides a cutting fluid recovery device for a numerically controlled machine tool, including a recovery tank 1; the recovery tank 1 is provided with a partition 101 in the middle and divided into a liquid storage cavity 102 and a spare cavity 103, and the upper end of the partition 101 is also inserted The overflow pipe 1011, the bottom end of the liquid storage cavity 102 is also provided with a liquid outlet pipe 1021, the bottom end of the spare cavity 103 is fixedly installed with the submersible pump 2, and the delivery pipe 201 is connected to the water outlet end of the submersible pump 2 and passes through the partition. The upper end of the plate 101 is inserted into the liquid storage chamber 102. The inner side of the liquid storage chamber 102 is also fixedly installed with a filter mechanism 3, and the filter mechanism 3 includes a filter frame 301 and a filter screen 303. The filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com