Lightweight partition board cutting device

A technology for lightweight partition boards and cutting equipment, applied in stone processing equipment, stone processing tools, work accessories, etc., can solve problems such as inconvenient use, cutting, uneven thickness of partition boards, etc., and achieve high work efficiency , The installation and cutting surface is smooth, and the end face is smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

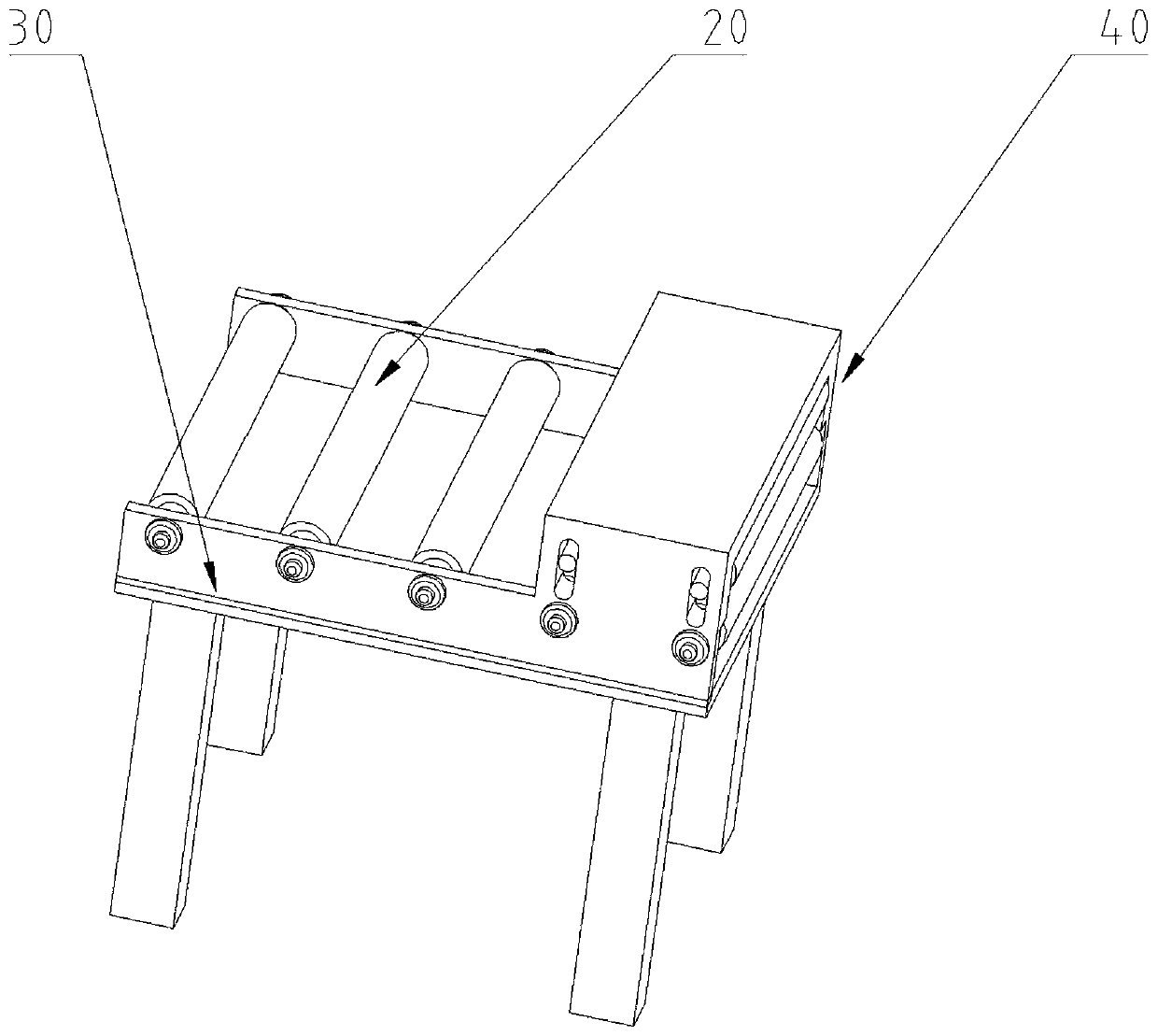

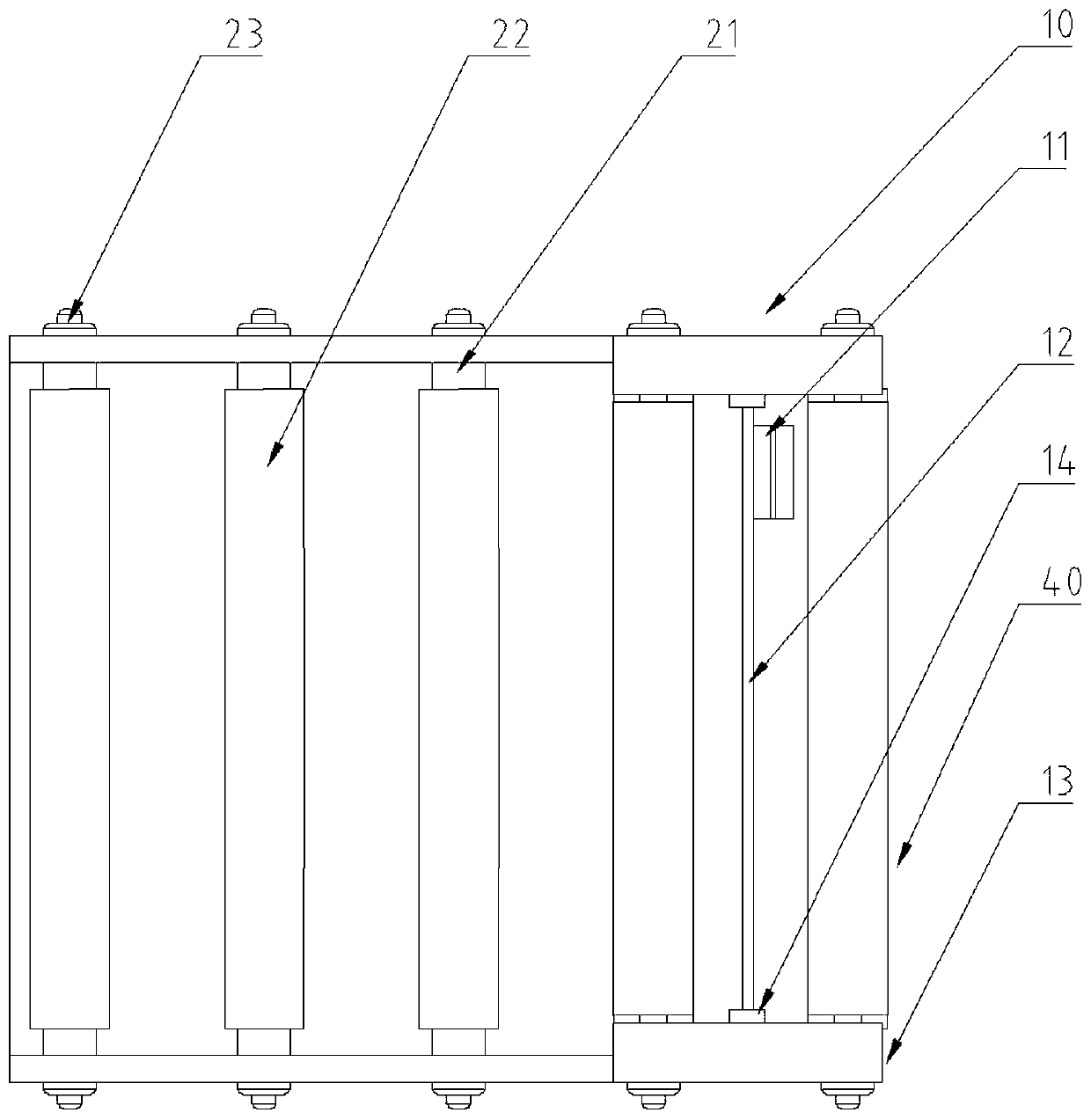

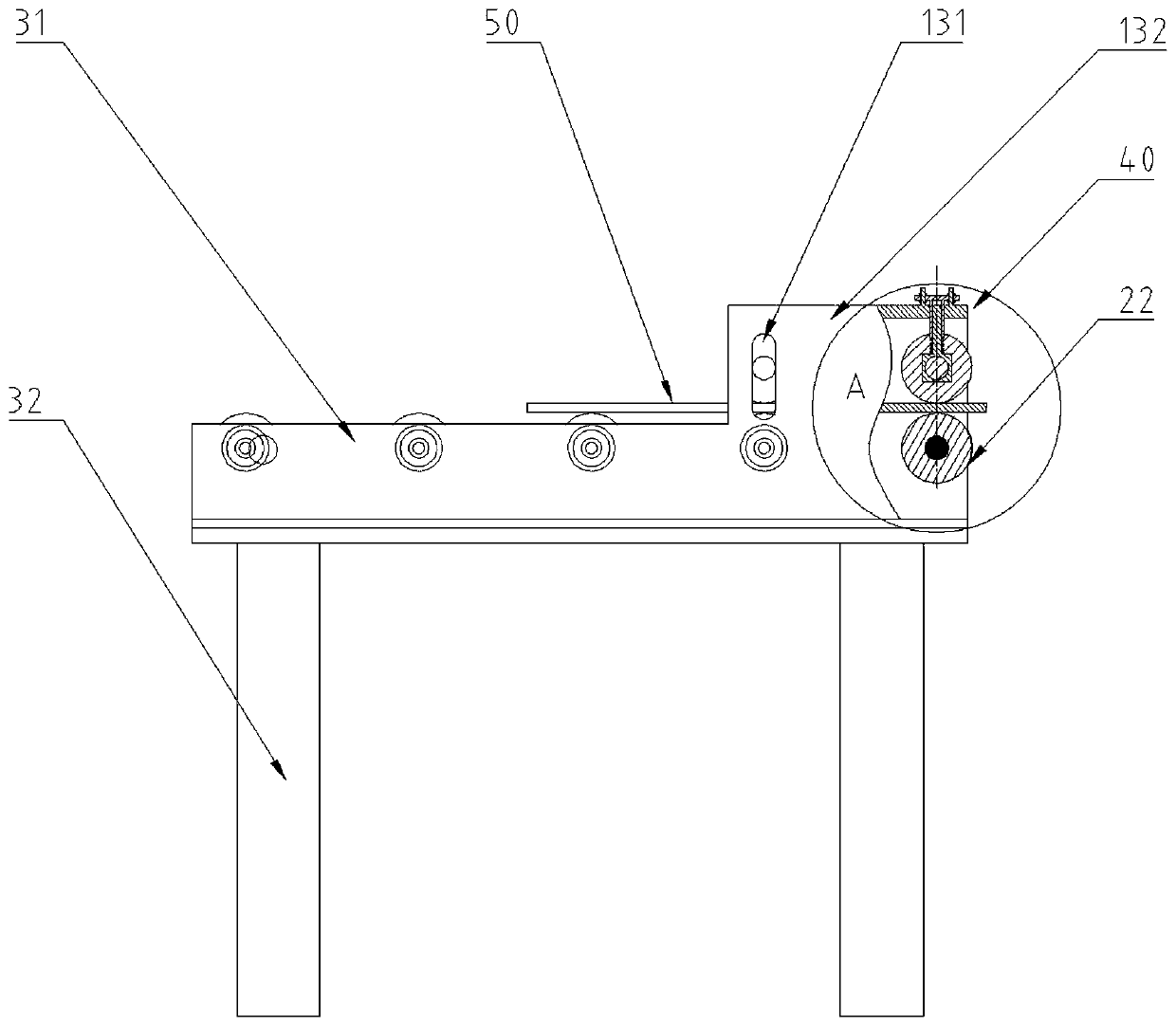

[0021] See Figure 1-3 , A lightweight partition wall cutting equipment, including a cutting mechanism 10, a transmission mechanism 20, a supporting mechanism 30, and a pressing mechanism 40. The cutting mechanism 10 includes a cutting machine 11, a horizontal slide bar 12, a vertical slide bar 14 and The fixing device 13 includes a fixing boss 131 and a limiting groove 132, the fixing boss 131 is symmetrically arranged on the supporting platform 31, and two limiting grooves 132 are symmetrically arranged on the fixing boss 131 , The vertical sliding rod 14 and the fixing boss 131 are detachably connected, preferably a threaded connection, and the horizontal sliding rod 12 and the vertical sliding rod 14 are slidingly connected, so that the horizontal sliding rod 12 can be It is free to move in the vertical direction, and the cutting machine 11 is slidably connected to the horizontal slide bar 12, and the cutting machine 11 can move in the horizontal direction and the vertical ...

Embodiment 2

[0030] See Figure 5 The difference between this embodiment and embodiment 1 is that the spring 43 in this embodiment is matched with the inner wall of the groove of the fixed block 42, one end is connected to the top of the movable block 44, and one end is the same as the The upper end surface of the groove of the fixed block 42 is matched, so that the movable block 44 can move up and down in the fixed block 42 and there is a spring 43 to restrict this movement.

[0031] The working principle of the present invention is: the lightweight partition wall is transported to the pressing mechanism 40 through the rotation of the roller 22, and the lightweight partition wall is moved by the pressing roller 45 located above and The roller 22 underneath is fixed, and the roller 22 is rotatably connected to the movable block 44. The movable block 44 and the fixed block 42 are slidably connected, and a spring 43 is arranged in the middle, which can adapt to different thicknesses. Lightweigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com