Variable-frequency ventilation system for cabin

A technology of ventilation system and variable frequency fan, applied in the direction of hull ventilation/heating/cooling, ship parts, ships, etc., can solve the problems of inability to control the air volume and air pressure of the engine room, poor energy saving effect, waste of electric energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

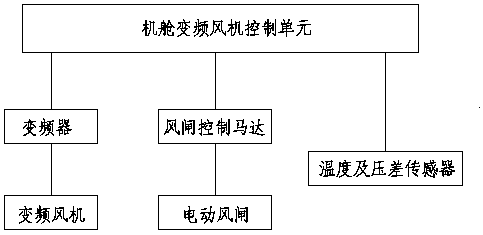

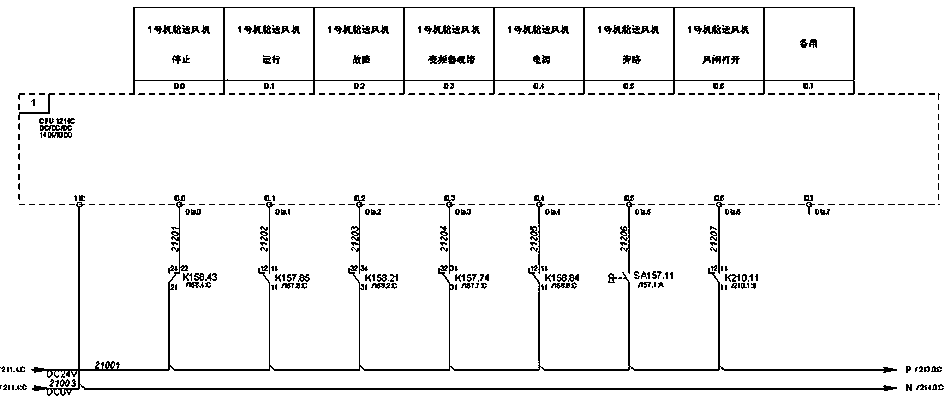

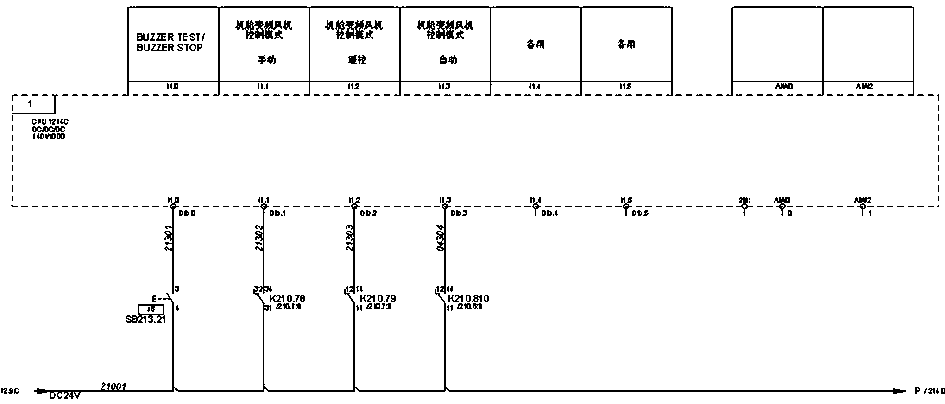

[0019] Including frequency conversion fan control system in engine room, IAS whole ship alarm system, frequency converter, damper control motor, temperature sensor, pressure difference sensor, frequency conversion fan and electric damper; The engine room frequency conversion fan control system, including the engine room frequency conversion fan control system including PLC and touch screen, each fan is equipped with a frequency converter to realize the frequency conversion control of the fan;

[0020] In the engine room, there are 2 differential pressure sensors, one for use and one for standby. The cabin maintains a slight positive pressure of 0-50Pa (can be set), when the pressure difference is higher than 100Pa (can be set) or lower than -20Pa (can be set set), an alarm will be issued (non-stop fan);

[0021] In the engine room, configure 5 temperature sensors and install them in places with typical characteristics. The average value of the measured temperature is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com