Case temperature control device

A temperature control device and chassis technology, which is applied in the direction of using gaseous coolant for modification, cooling/ventilation/heating transformation, electrical components, etc., can solve the problem of inability to measure the external temperature, affect the operation of the whole station, and cannot effectively monitor the operating status of the chassis fan And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

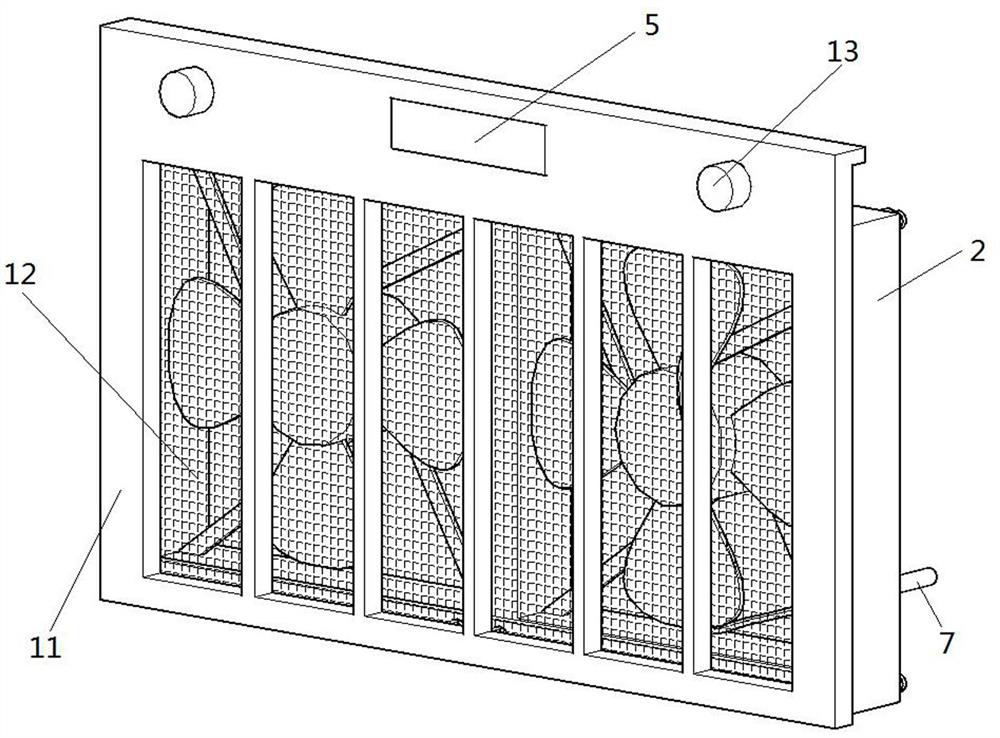

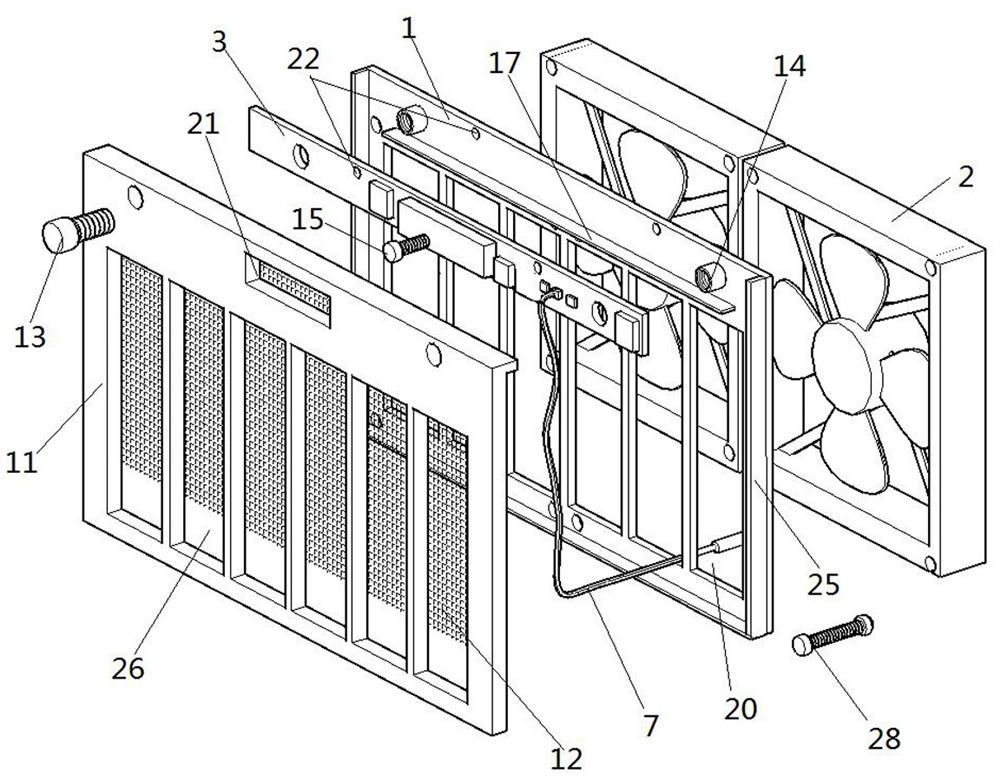

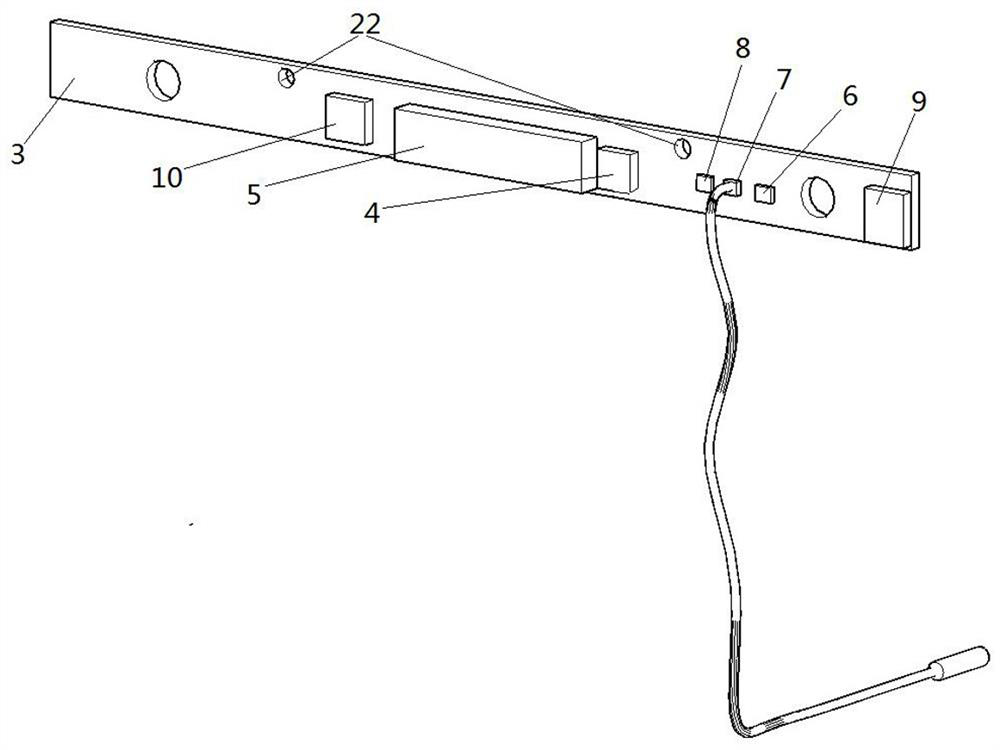

[0033] Such as Figure 1-3 Shown is the first embodiment of the present invention, a chassis temperature control device, including a fixed frame 1, the fixed frame 1 is a cuboid plastic plate made of epoxy resin, the lower part of the fixed frame 1 is hollowed out, and is uniformly cut by a cutting machine Out of multiple through holes a 20, such as figure 1 and figure 2 As shown, two exhaust fans 2 are installed on the lower part of the rear of the fixed frame 1 through bolts 228. The model of the exhaust fan 2 is FD128025EB-N, and the upper part of the front of the fixed frame 1 is not hollowed out. image 3As shown, a central processing unit 4 is set on the circuit board 3, the central processing unit 4 is an MPU, the model is STM32F103C8T6, a power supply module 10 is set on the circuit board 3, a display 5, a temperature sensor 2 7, a real-time clock 8 and a TF card 9 are also set , the model of display 5 is DIG2841BS, the model of temperature sensor 1 6 is DS18B20, th...

Embodiment 3

[0038] Such as Figure 5 Shown is the third embodiment of the present invention. The difference between this embodiment and the first embodiment is that a differential pressure switch 18 is mounted on the horizontal plate 17 through screws, an indicator light 19 is mounted on the circuit board 2, and the power module 10 is The switch 18 is electrically connected with the indicator light 19. When the pressure difference on both sides of the filter screen 12 reaches a certain value, the pressure difference switch 18 is closed, and the indicator light 19 is on, indicating that the filter screen 12 is full and needs to be replaced. Machine punches the through hole five 24 that matches with indicator lamp 19.

Embodiment 4

[0040] Such as Figure 6 Shown is the fourth embodiment of the present invention, the difference between this embodiment and the first embodiment is that the clock backup battery 27 provides backup power for the real-time clock 8, the model of the clock backup battery 27 is CR1220, and the clock backup battery 27 is set at on circuit board 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com