Control method for automatically positioning intelligent logistics conveying line

A technology of automatic positioning and control method, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of material blocking and leakage, and the inability of objects to be accurately conveyed to the designated operating station by automatic logistics conveyor lines. Achieve accurate and efficient transportation, ensure the success rate of transportation, and ensure the effect of transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

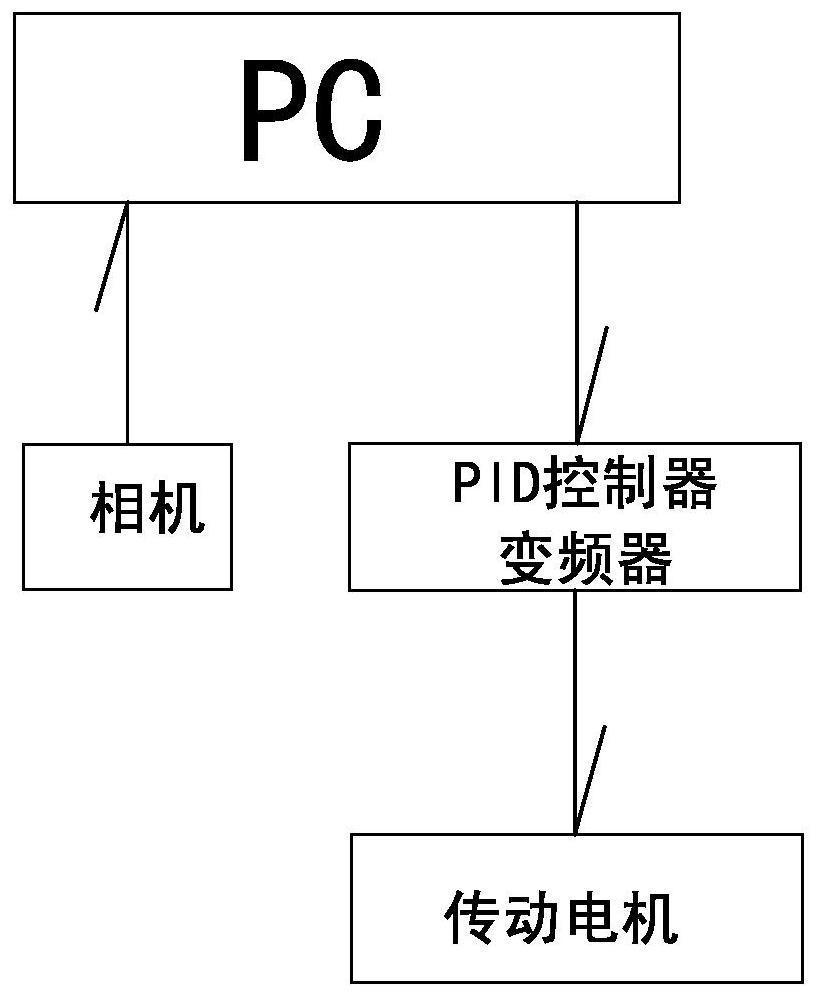

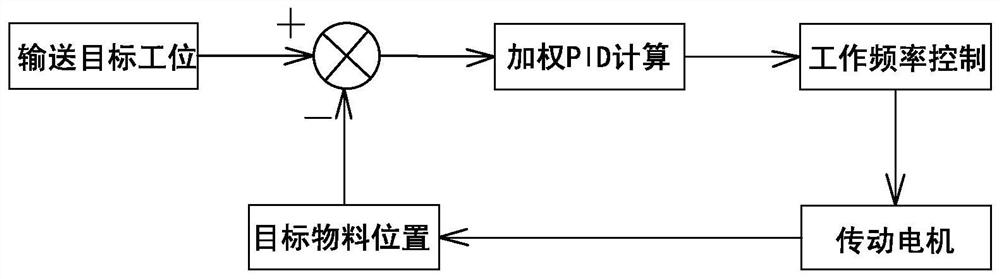

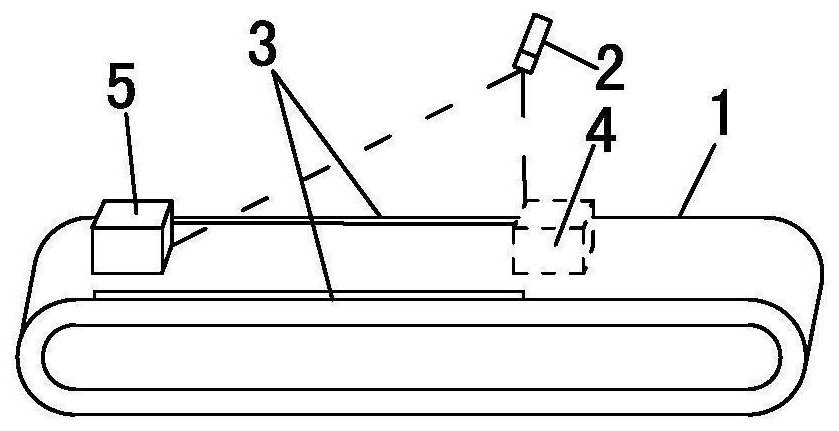

[0025] The invention discloses a control method for automatically positioning a smart logistics conveying line, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, above the conveying line 1 is installed a camera 2 for obtaining the material situation on the conveying line 1 (this camera 2 can be an industrial camera suitable for industrial applications, which is an existing product with different functions camera) and the sorting mechanism 3 set on the side of the conveyor line 1 to push back the materials blocked on the side of the conveyor line 1 to the conveyor line. The conveying action of the conveyor line 1 is realized by the transmission motor The driving is realized, and the driving work of the transmission motor is controlled by a frequency converter, and the operating frequency of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com