The method of using uasb-sbr-eo to treat early landfill leachate to realize deep carbon removal, nitrogen removal and desulfurization

A technology of UASB-SBR-EO and landfill leachate, which is applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problem of high treatment cost and achieve high treatment efficiency and strong driving force , the effect of preventing sludge bulking

Active Publication Date: 2022-03-29

BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This process does not need to add any carbon source for deep denitrification, which is different from other conventional landfill leachate treatment processes, and solves the key problem of high treatment costs caused by the need to add a large amount of carbon source in the denitrification and denitrification process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

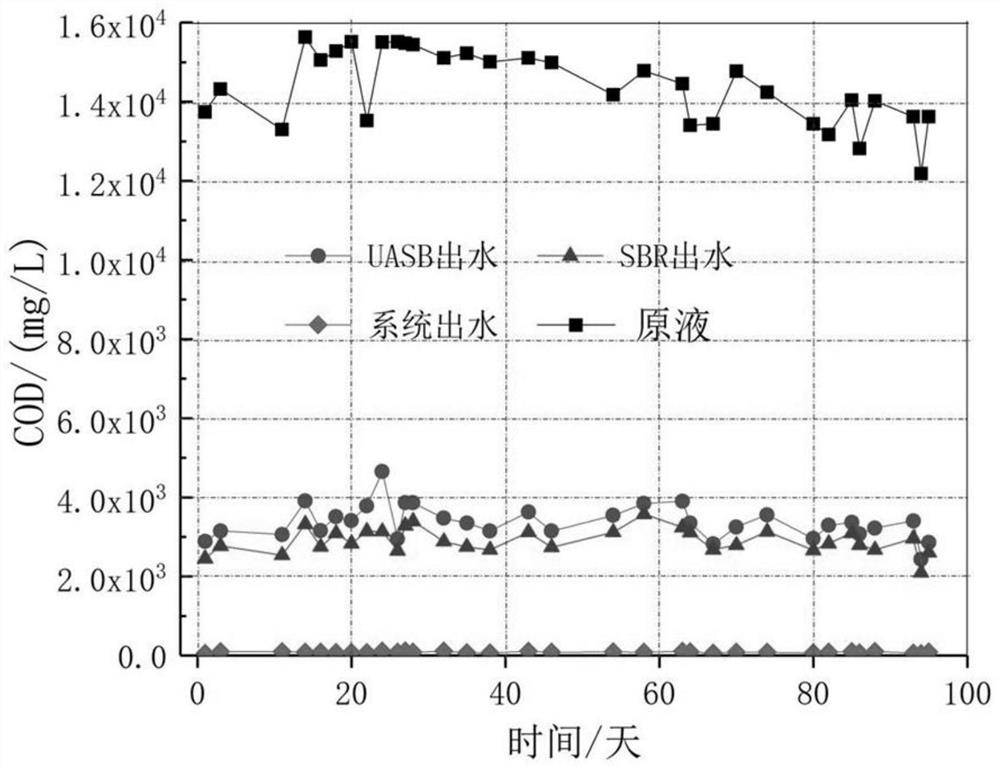

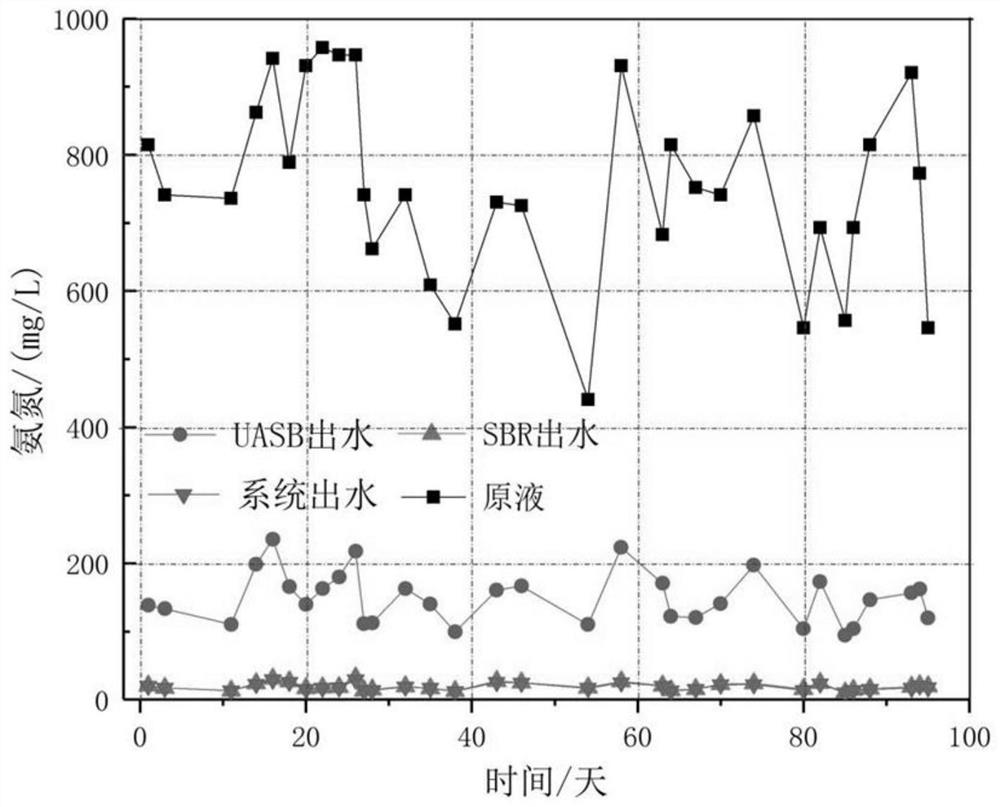

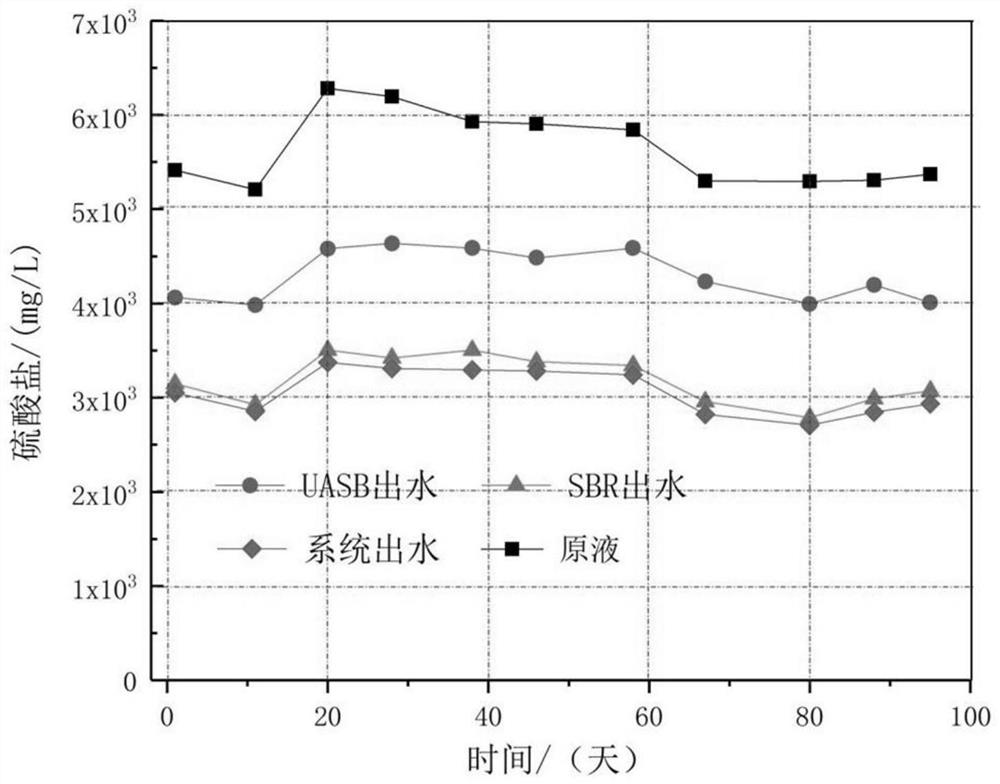

[0040] Combined example: The experimental water is taken from the untreated early landfill leachate of a landfill in Beijing. The water quality is as follows: CODcr is 10000-30000mg / L, NH 4 + -N is 500-1000mg / L, NO x - -N is 0.1-5mg / L, SO 4 2- It is 10000-15000mg / L.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

UASB‑SBR‑EO’s process for treating early landfill leachate to achieve deep carbon, nitrogen, and desulfurization belongs to the technical field of carbon, nitrogen, and desulfurization, and is widely applicable to the advanced treatment of high-concentration organic sewage, especially for the deep removal of early landfill leachate. The effect of carbon denitrification and desulfurization is remarkable. Firstly, the UASB process is used for front-end pretreatment to efficiently remove degradable COD and provide a good physical and chemical environment for the subsequent anammox reactor; the process uses SBR as the anaerobic ammonium oxidation reactor to reasonably control pH and DO. In the case of adding external carbon sources, the advanced treatment of early landfill leachate is realized, that is, the simultaneous removal of organic matter, ammonia nitrogen, and sulfate; the electro-oxidation process is strictly controlled to deeply remove refractory organic matter. The concentrations of organic matter, ammonia nitrogen, and sulfate in the final effluent were 87.511mg / L, 18.545mg / L, and 3065mg / L, and the removal rates of organic matter, ammonia nitrogen, and sulfate were 99.4%, 97.6%, and 79.9%, respectively, and completely Comply with sewage discharge requirements.

Description

technical field [0001] The invention relates to a waste water combined treatment method and device, mainly for deep carbon removal, nitrogen removal and desulfurization for early landfill leachate with high ammonia nitrogen and high organic matter. The process is equipped with an inlet water tank, an upflow anaerobic sludge bed reactor (UASB), an intermediate water tank, a sequencing batch reactor (SBR), an intermediate water tank and an electro-oxidation (EO) device. When the wastewater flows through the UASB, anaerobic biological reaction occurs, which can remove most of the organic matter, and convert the organic nitrogen into ammonia nitrogen during anaerobic decomposition; the intermediate water tank is used to adjust the pH, temperature and other influencing factors; in the SBR, the sub Nitrate-type anaerobic ammonium oxidation and sulfate-type anaerobic ammonium oxidation reactions realize biological simultaneous denitrification and sulfur removal; the effluent passes t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F9/14C02F101/10C02F101/16C02F101/30C02F103/06

CPCC02F3/307C02F1/4672C02F2101/16C02F2101/166C02F2101/101C02F2103/06C02F2101/30C02F2305/023

Inventor 吴莉娜李进闫志斌

Owner BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com