High nitrogen-containing landfill leachate processing method and apparatus

A technology of high-nitrogen garbage and treatment device, which is applied in the field of biological sewage treatment, can solve the problems of difficult biological treatment of high-ammonia-nitrogen landfill leachate, etc., and achieves the effects of good denitrification and phosphorus removal, improved removal efficiency, and high load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

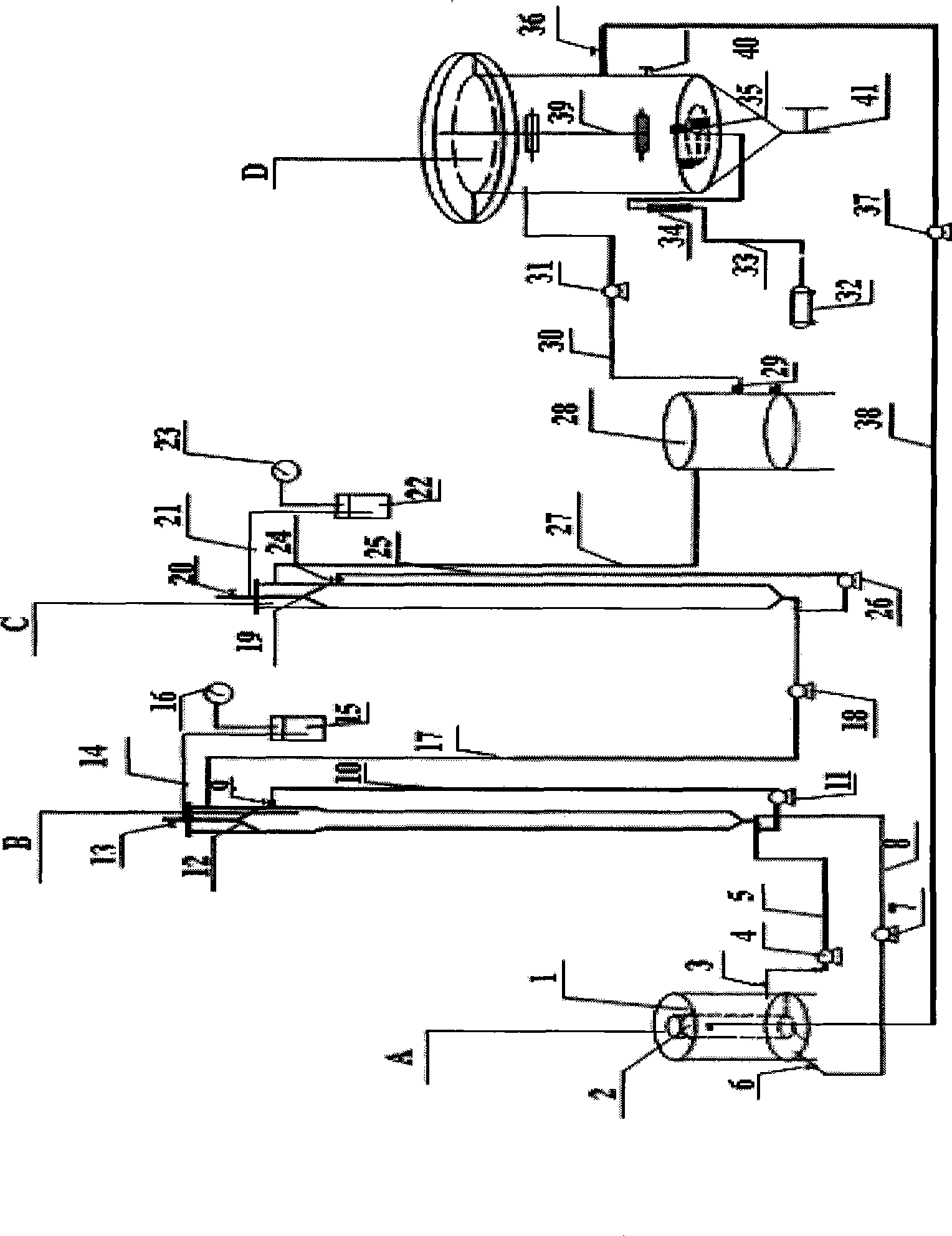

[0036] See figure 1 , The specific process of the present invention for the treatment of landfill leachate is:

[0037] The leachate flows from the original leachate zone 1 through the UASB1 leachate feed pump 4 and the refluxed SBR nitrification supernatant into the UASB1 reactor B. The denitrifying bacteria and anaerobic methanogens in the reactor make full use of the abundant influent water The organic matter undergoes anoxic denitrification and anaerobic methane production reaction, so that the organic matter is fully degraded. The effluent of the UASB1 reactor B enters the UASB2 reactor C from the bottom through the UASB2 water inlet pump 18, and the remaining organic matter in the UASB1 reactor C effluent is further removed by the anaerobic action of methanogens. The effluent water of UASB2 reactor C flows to the intermediate water tank 28 by gravity. After the two-stage UASB treatment, the leachate enters the SBR reactor D. First, through the aerobic respiration of heterot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com