Anti-backflow centrifugal fan system

A centrifugal fan and anti-backflow technology, applied in radial flow pumps, cooling/ventilation/heating transformation, components of pumping devices for elastic fluids, etc., can solve the problem of temperature rise of electronic components and acceleration of electronic components Aging, affecting user experience and other issues, to achieve the effect of accelerating aging, reducing backflow, and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] The terms used herein in the description of the present invention are for the purpose of describing specific embodiments only, and are not intended to limit the present invention. As used herein, the term "and / or" includes any and all combinations of one or more of the associated listed items.

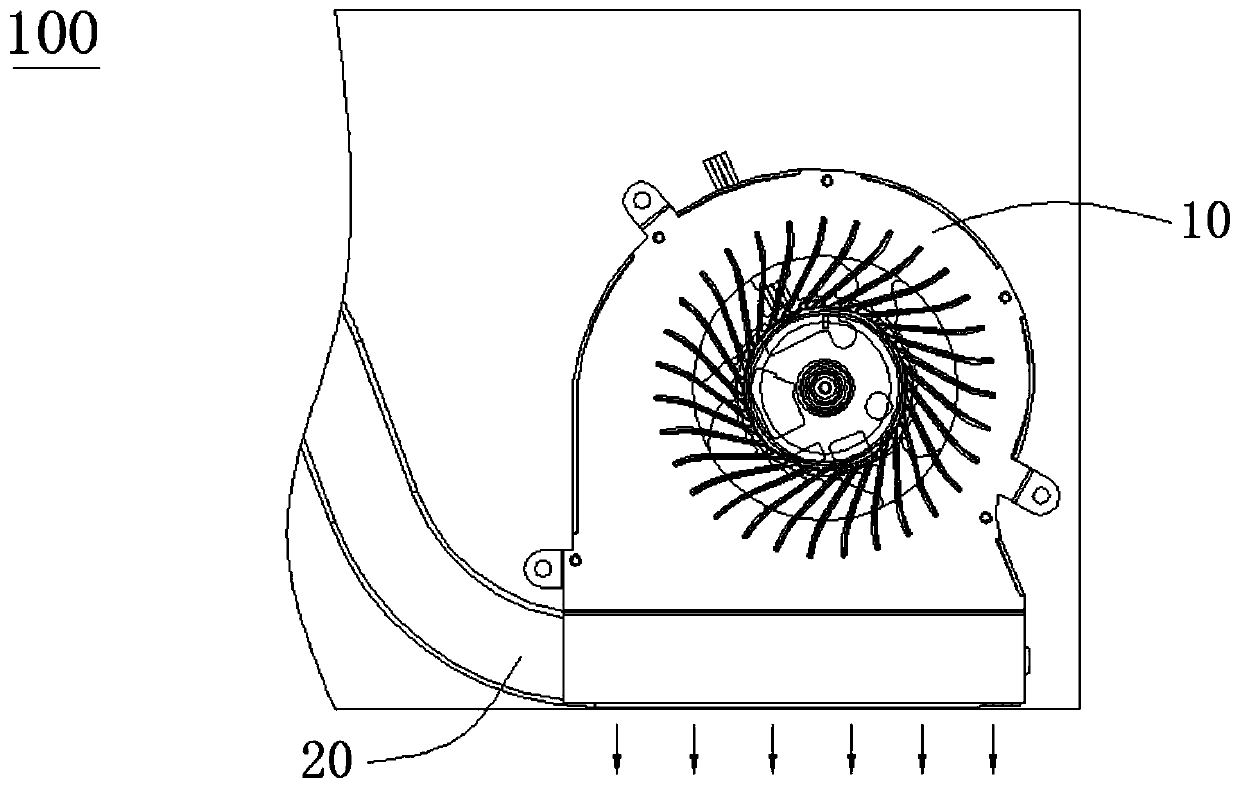

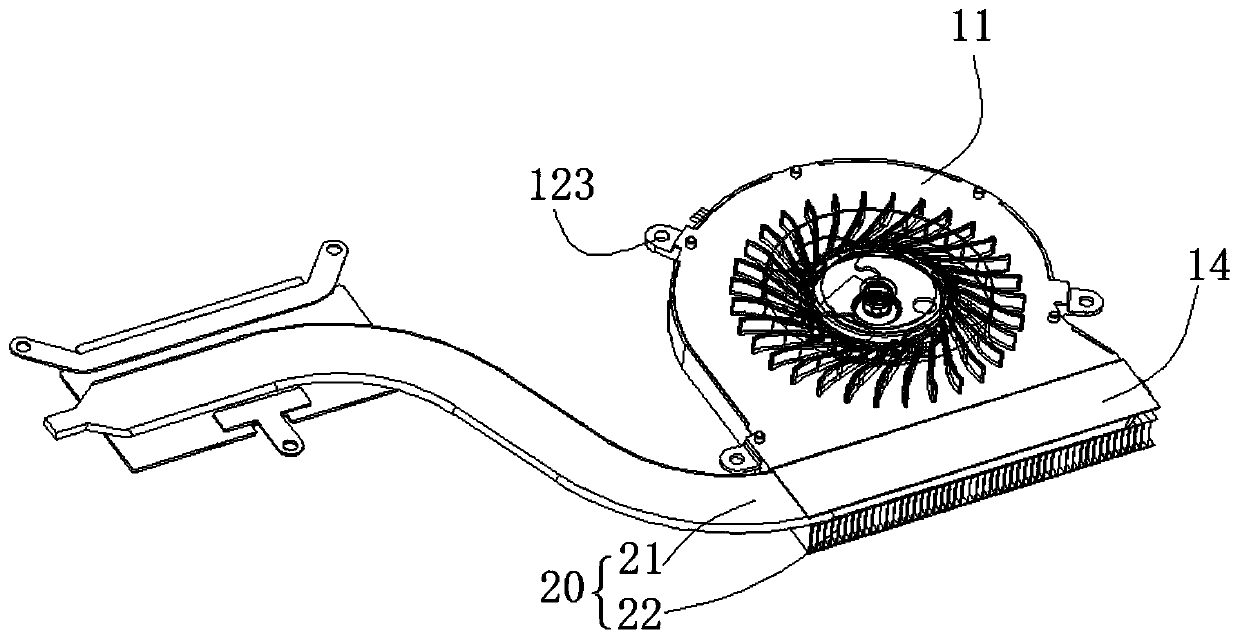

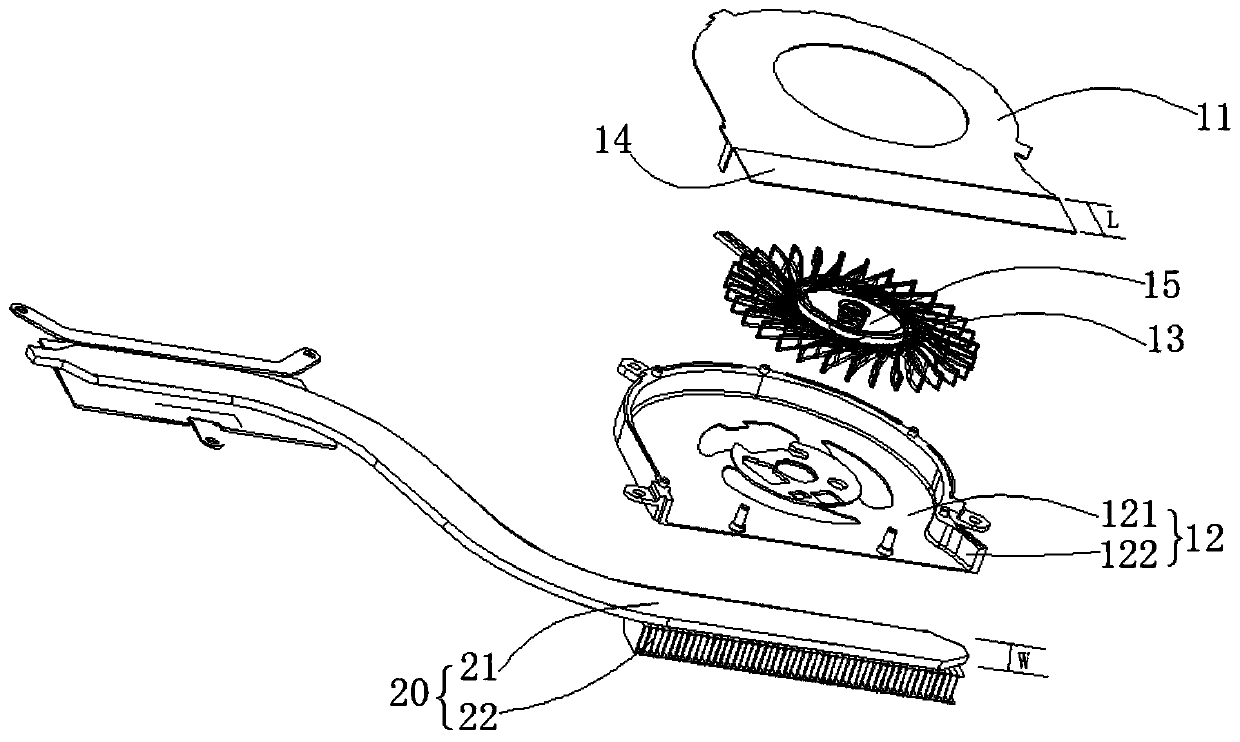

[0025] Please also refer to figure 1 , figure 2 and image 3 , is an anti-backflow centrifugal fan system 100 provided by an embodiment of the present invention.

[0026] The anti-backflow centrifugal fan system 100 includes an anti-backflow centrifugal fan 10 and a cooling module 20; the anti-backflow centrifugal fan 10 includes: an anti-backflow fan upper cover 11, a centrifugal fan lower cover 12, a centrifugal fan blade 13 and T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com