Full-rolling movable tooth one-tooth-difference planetary speed reducer

A planetary reducer, movable tooth technology, applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of not eliminating large sliding friction, unsuitable for high-power transmission, and complex structure of the movable gear frame. , to achieve the effect of simple structure, long life and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

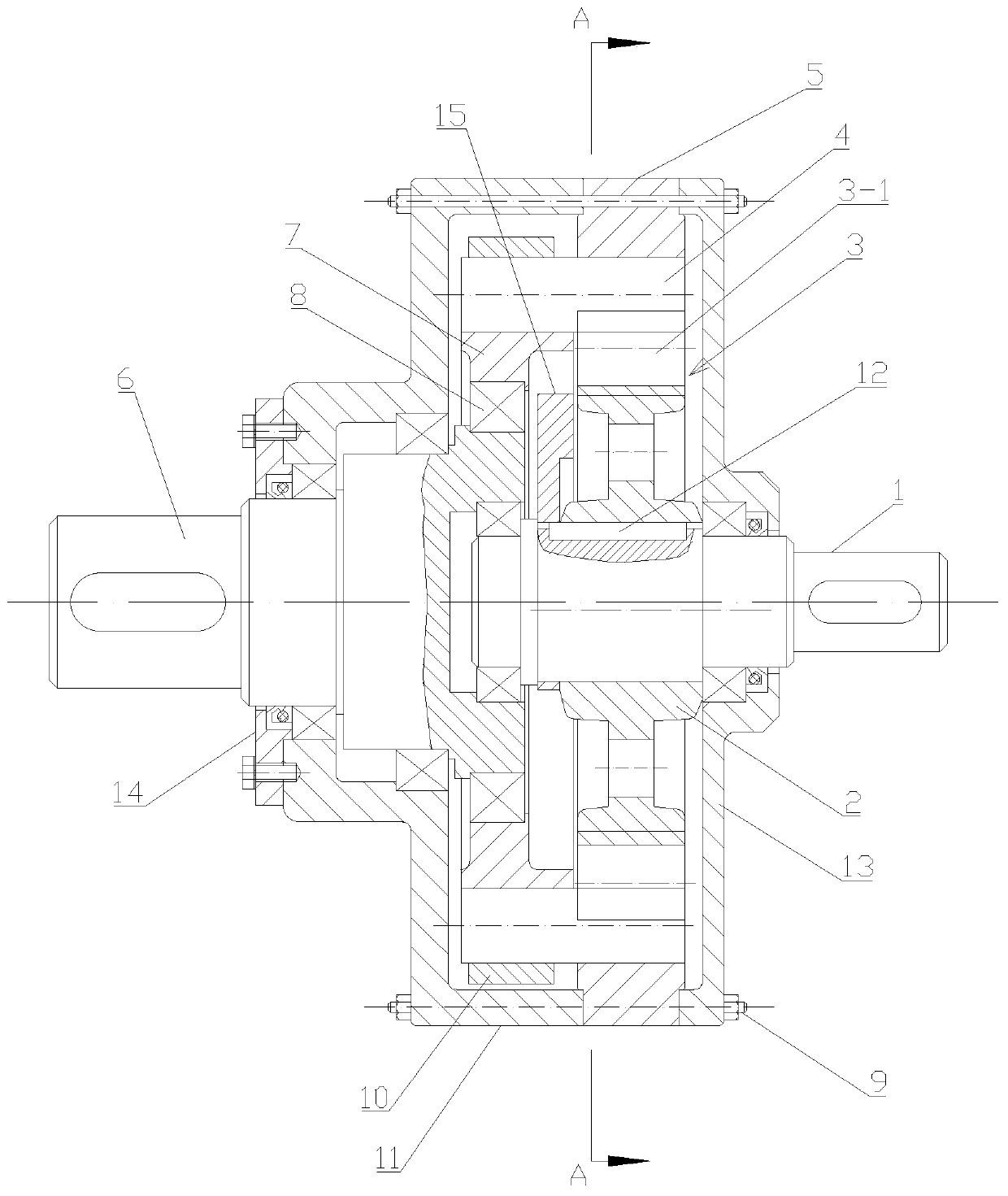

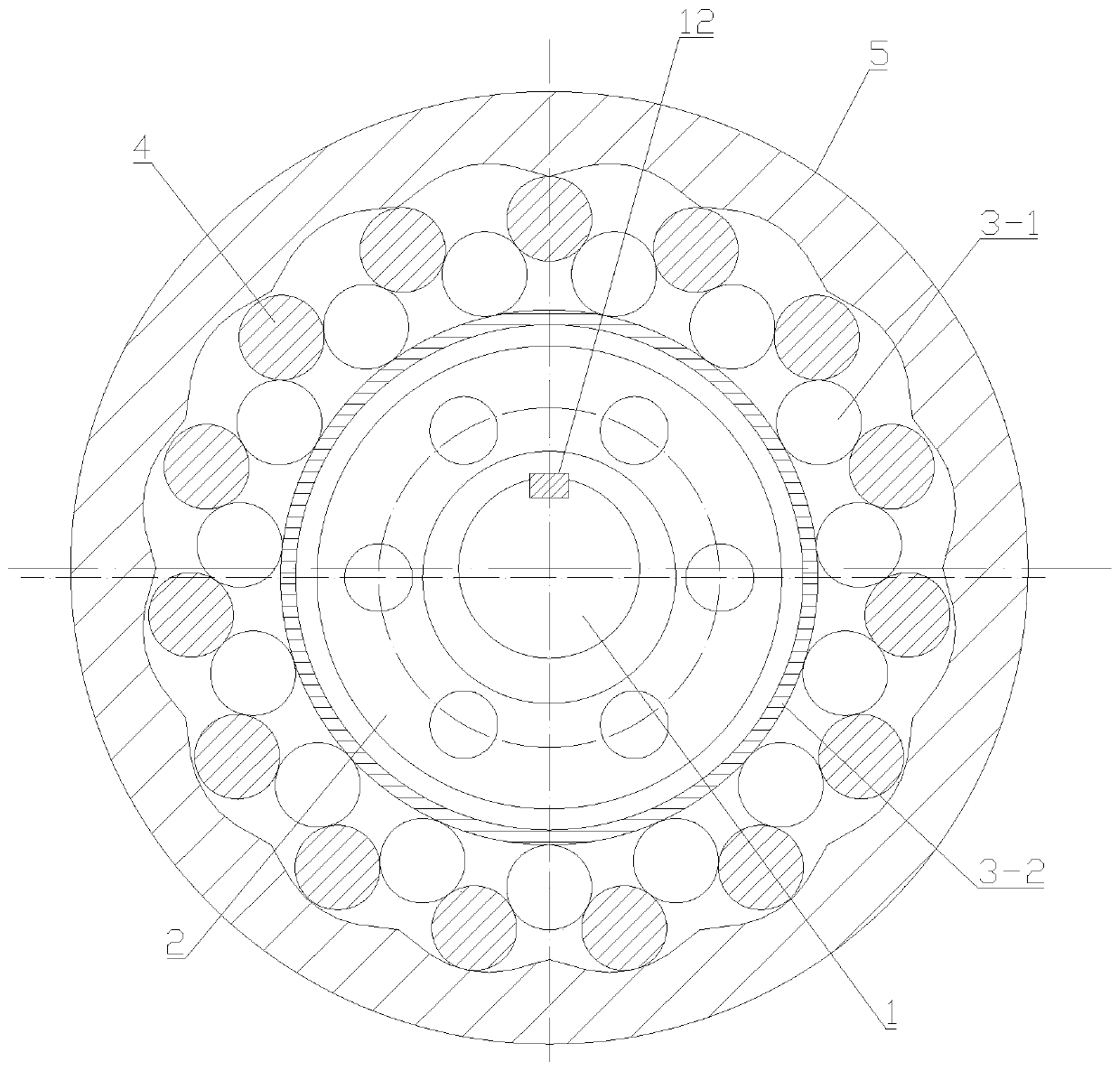

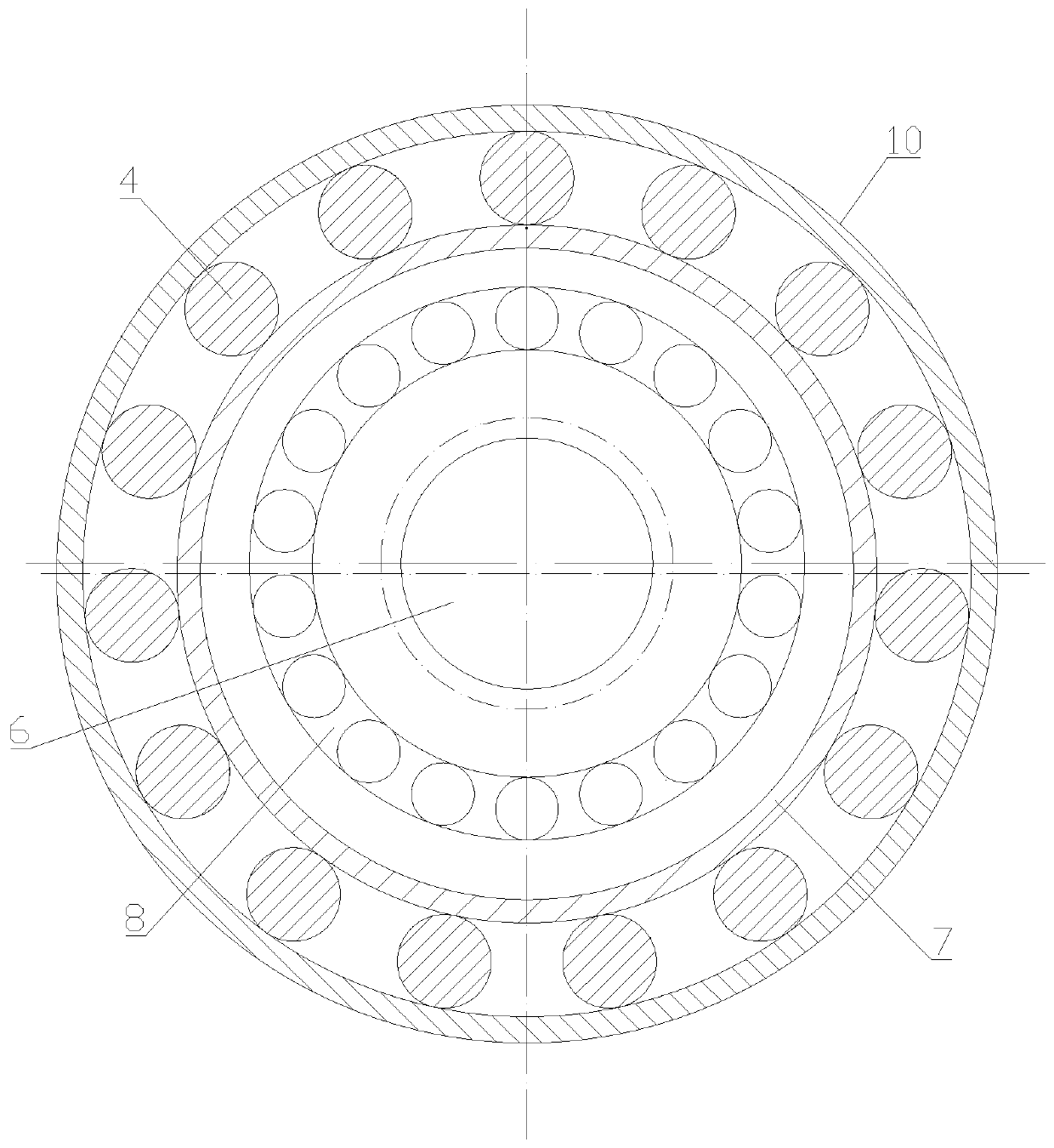

[0033] Such as figure 1 , figure 2 with image 3 As shown, the present invention includes a rolling-type input mechanism and an eccentric ring-type output mechanism, between which the input mechanism and the eccentric ring-type output mechanism perform reduction transmission in a rolling manner through a tooth difference planetary transmission mechanism, and the input mechanism includes The input shaft 1 and the eccentric sleeve 2 sleeved on the input shaft 1, the one-tooth difference planetary transmission mechanism includes the inner ring gear 5 and the movable ring gear arranged in the inner ring gear 5, and the movable ring gear includes a plurality of The movable tooth 4 meshed with the tooth profile of the inner ring gear 5, and the arm bearing 3 without outer ring which can play the role of the tooth seat ring is arranged between the input end of the movable ring gear and the outer ring of the eccentric sleeve 2, The input end of the movable tooth 4 in the movable ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com