Gear pitch deviation measuring method and measuring tool thereof

A technology of deviation measurement and gear teeth, applied in the field of measuring tools, can solve the problems of difficult control of errors and affect the accuracy of measurement, and achieve the effect of accurate lateral movement and positioning, convenient adjustment and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention will be described in detail below.

[0050] A method for measuring gear pitch deviation, the method comprising the following steps:

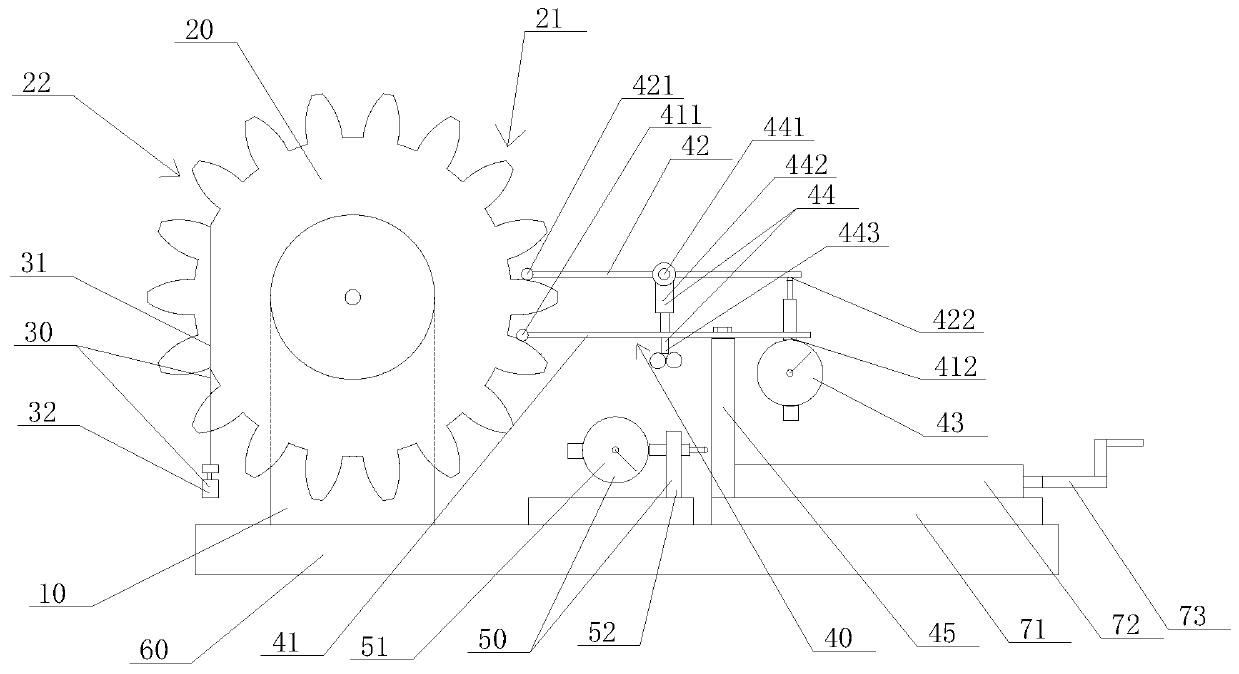

[0051] (1) Install the gear under test 20 vertically on the upper end of the shaft support 10, adjust the heights of the fixed claw 41 and the movable claw 42 of the pitch measuring mechanism 40, so that the measured reference teeth of the gear under test 20 are located at Between the fixed jaw 41 and the movable jaw 42;

[0052] (2) The measuring force weight 32 is hoisted on the constant force applying side 22 of the tested gear 20 by the lanyard 31, and then the sliding tooth pitch measuring mechanism 40 approaches the tested gear 20, so that the movable measuring head of the movable claw 42 421 and the fixed measuring head 411 of the fixed jaw 41 come into close contact with the middle position of the tooth center of the measured reference tooth;

[0053] (3) The measuring head of the second dial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com