Constant-beam-width biconical array and constant-beam-width biconical array beam forming method

A constant beam width, cone-shaped technology, used in positioning, radio wave measurement systems, instruments, etc., can solve the problem of inability to accurately obtain the accurate value of radiated noise in the same area, so as to improve the ability of broadband detection and estimation, reduce the number of applications, and improve the The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following examples describe the present invention in more detail.

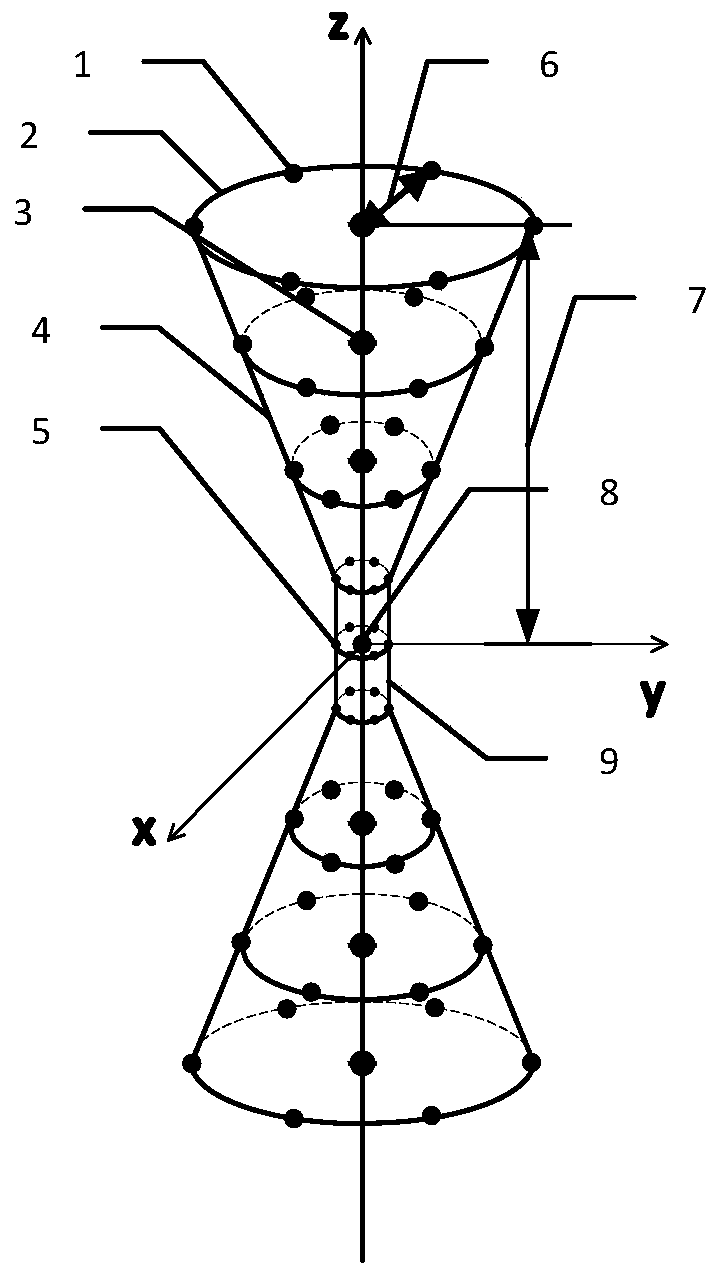

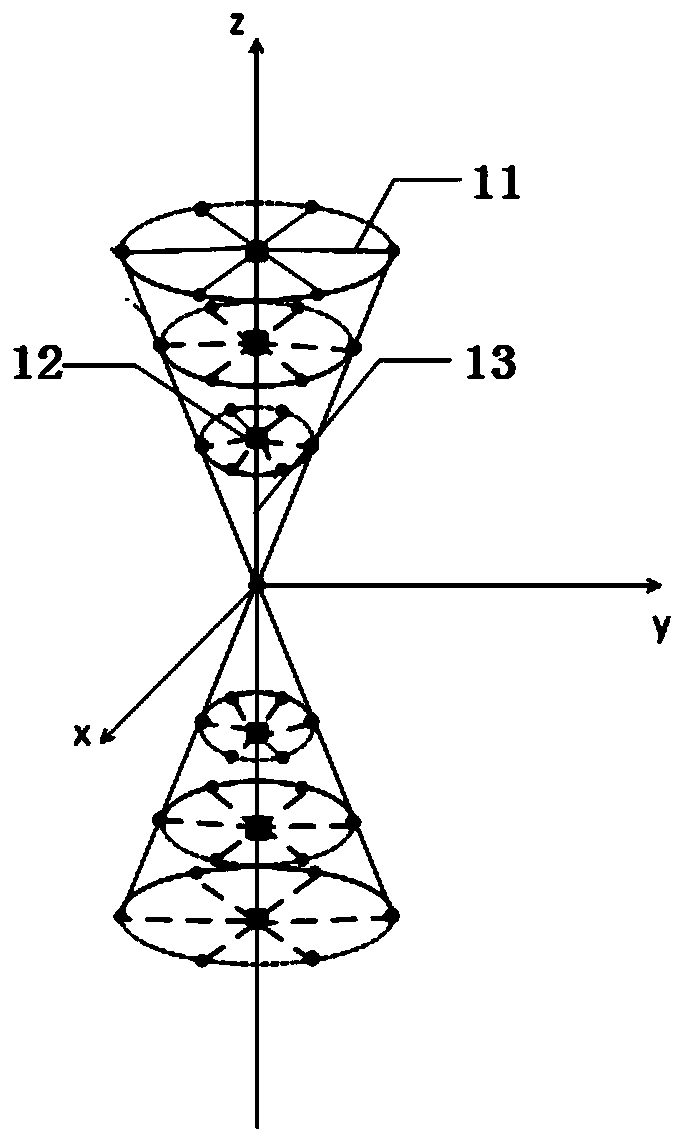

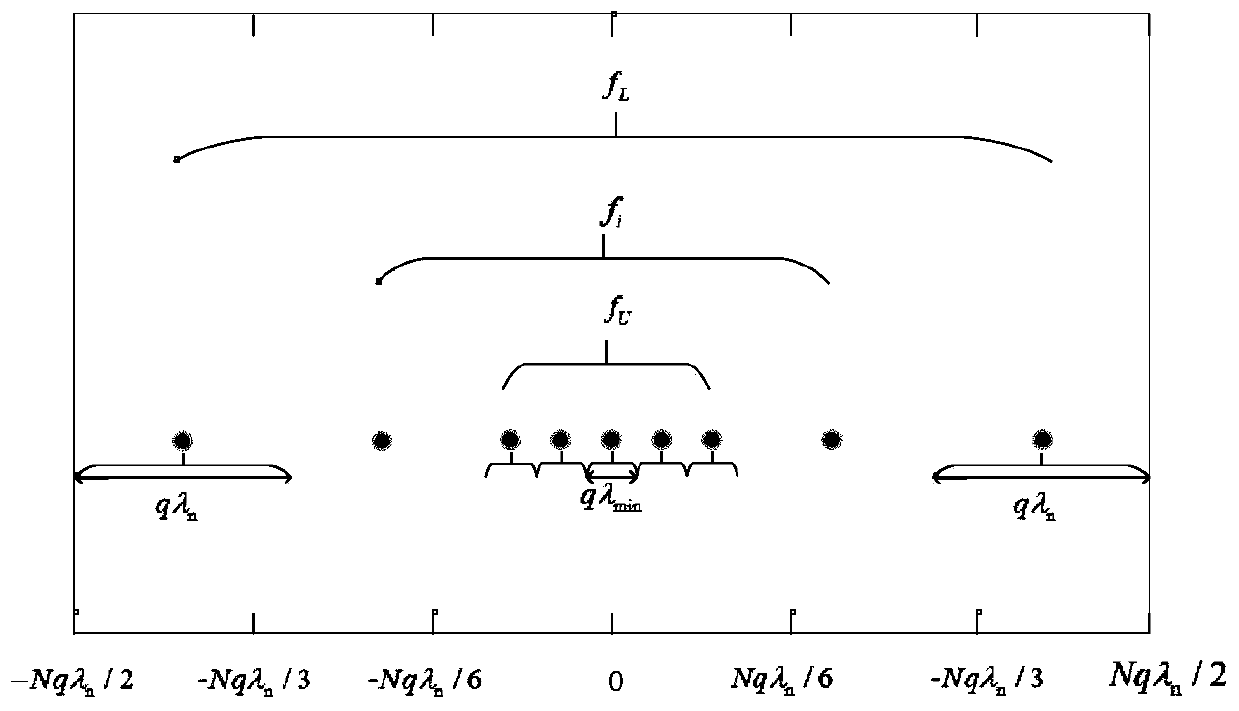

[0036] combine figure 1 , The composition of the first embodiment of the constant beam width bicone array of the present invention includes a vector hydrophone 1 and a vector hydrophone fixing frame. The vector hydrophone fixing frame includes two groups of circular frames 2 with decreasing radii and two conical frames 4 connecting the circular frames with decreasing radii into a cone shape. The same number of vector hydrophones is suspended on each circular frame to form a circular array, a group of circular arrays with decreasing radii are connected by a cone frame to form a cone array, and the tops of two cone arrays are connected to form a double cone array. figure 1 Among them, the circular frame is a circular frame, 6 represents the radius of the circular array, and 3 represents the center position of the circular array; each circular array includes 6 vector hydrophones, and each vector hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com