A porous medium water separator for fuel cells

A porous medium and fuel cell technology, applied in fuel cells, fuel cell control, fuel cell additives, etc., can solve problems such as solenoid valve failure, corrosion, and reduced system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

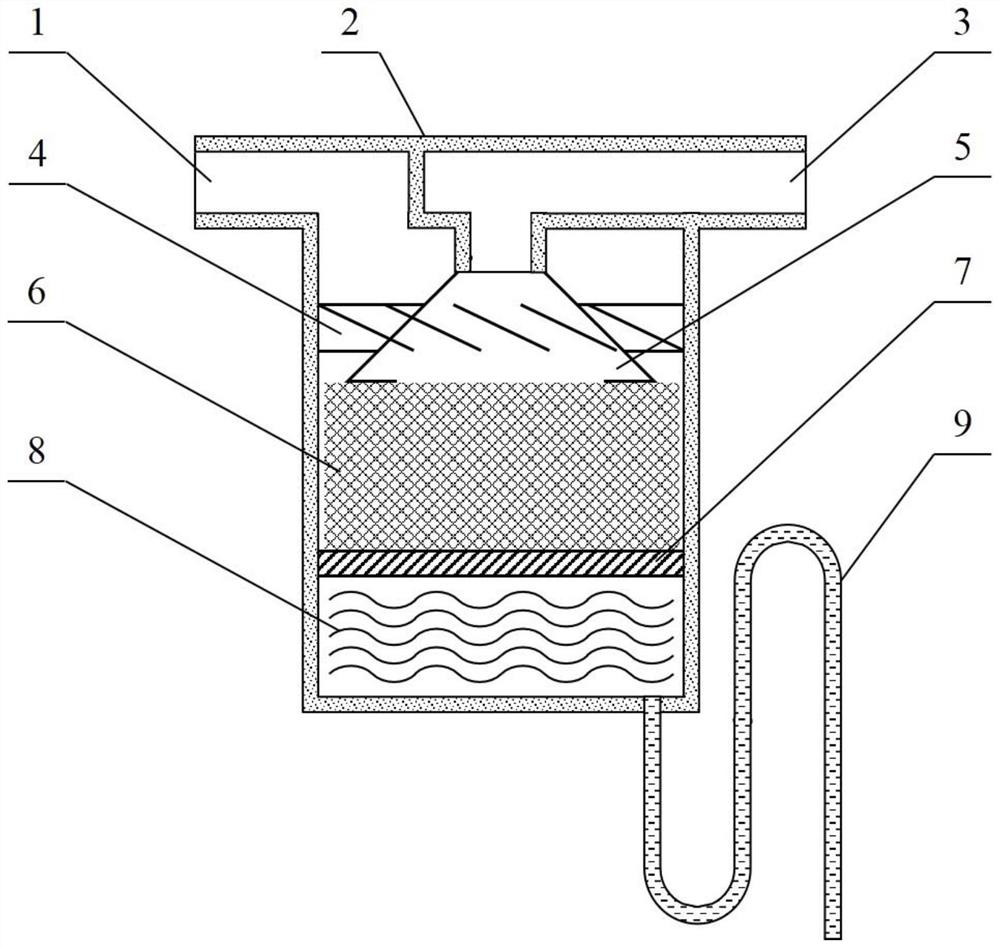

[0024] This embodiment is a water separator for the air outlet of the fuel cell. Including the container 2, the container 2 is provided with an air inlet 1, an air outlet 3 and a drain pipe 9; a porous medium plate 7 is arranged in the container 2 (the porous medium plate 7 uses a porous graphite plate, and its aperture is 12 μm , the contact angle is 63 °), the porous medium plate 7 is fixedly connected with the inner wall of the container 2 shell, and the container 2 is divided into an air cavity above the porous medium plate 7 and a water cavity positioned at the bottom of the porous medium plate 7; in the air cavity Among them, fins 4, flow splitter 5 and filter element 6 are arranged (the filter element uses a sponge).

[0025] When in use, the air inlet 1 of the water separator is connected with the air outlet 3 of the fuel cell, the air outlet 3 of the water separator is connected with the exhaust gas discharge pipeline, and its drain pipe 9 is connected with the liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com