Feed batching device for livestock and pigs

The technology of feed and pretreatment device is applied in the field of feed batching device for animal husbandry and pig breeding, which can solve the problems of uneven feed nutrients, reduce feeding effect, etc., and achieve the effects of avoiding repeated heating, avoiding feed waste and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

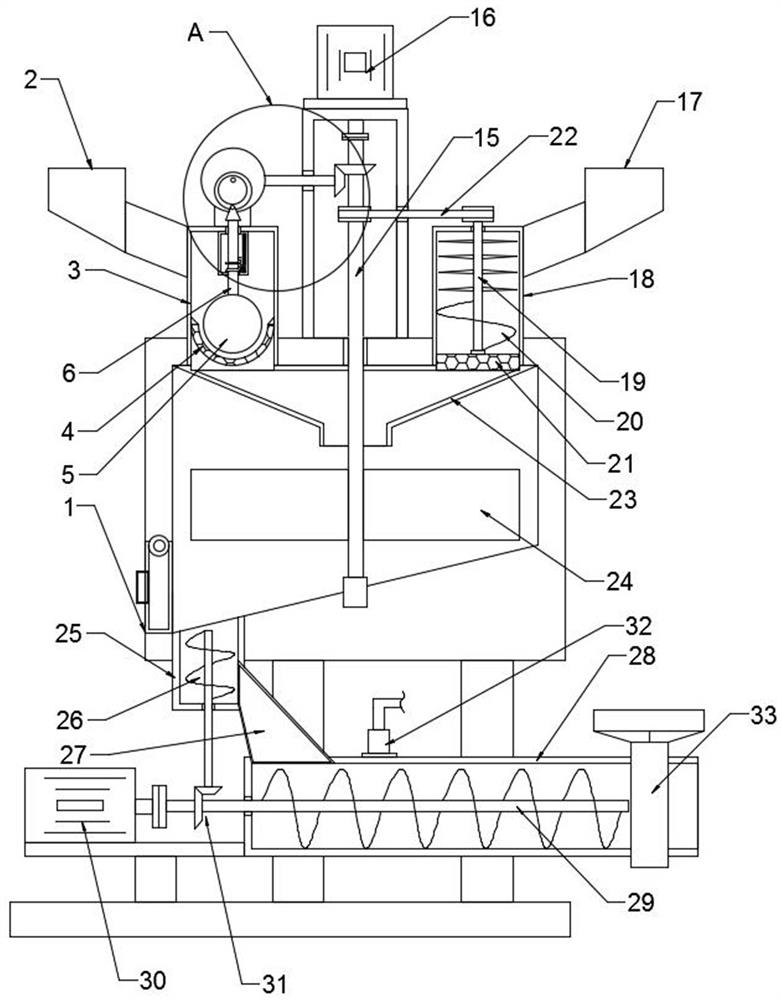

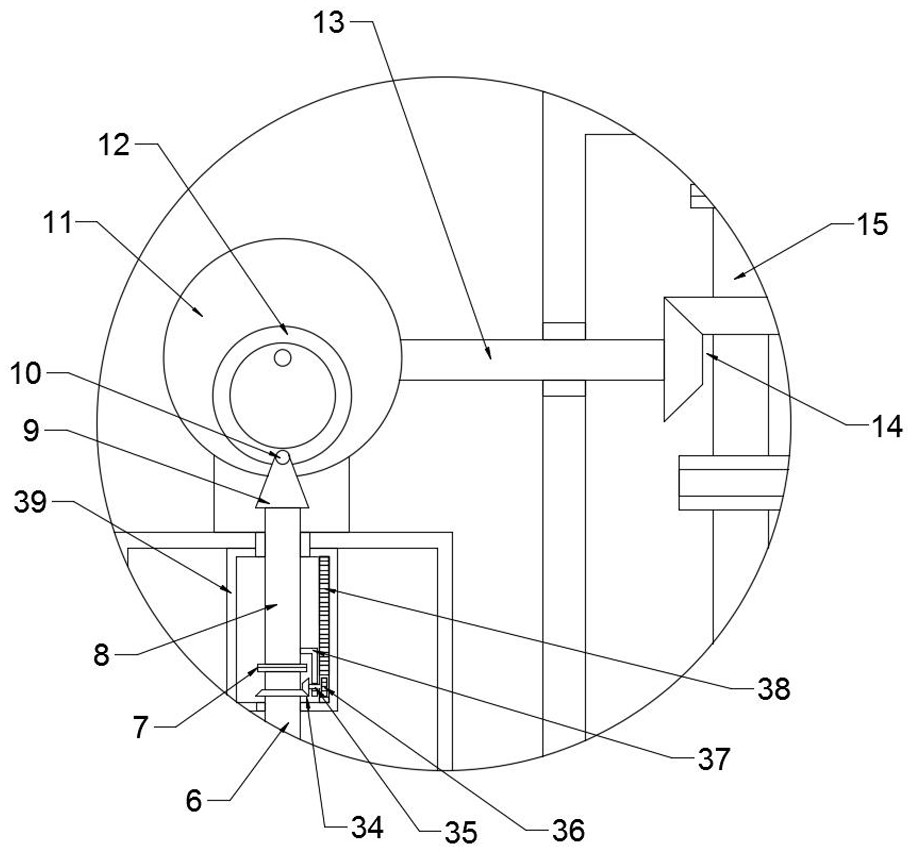

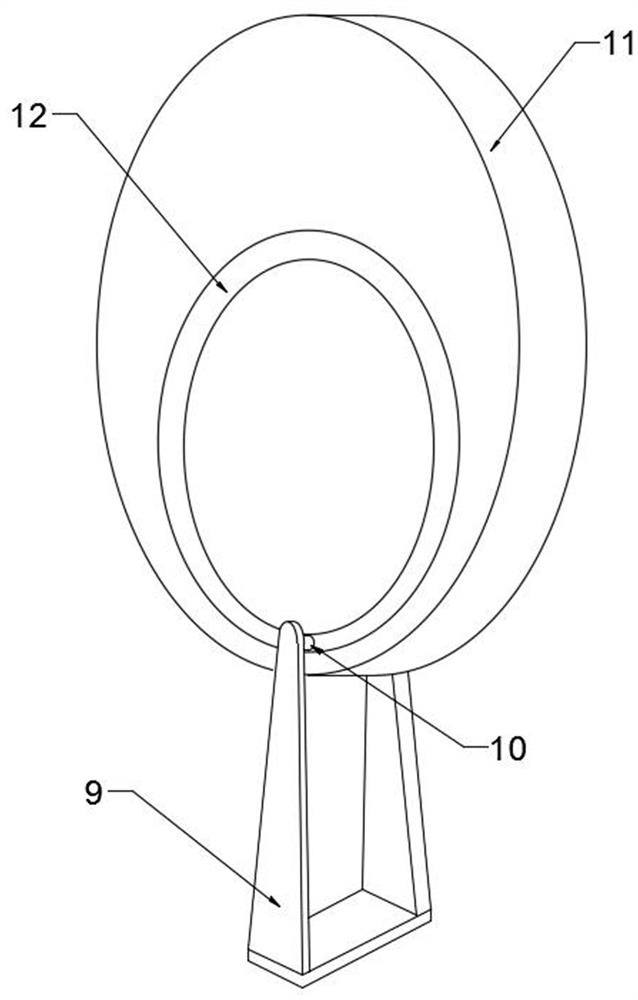

[0021] see figure 1 , in an embodiment of the present invention, a feed batching device for animal husbandry and raising pigs includes a mixing box 1 and a feed pretreatment device; Crushing cylinder 18; the upper end of the crushing cylinder 3 is connected with the first feeding hopper 2, and the lower end of the crushing cylinder 3 is connected with the mixing box 1, and granular feed such as soybeans and corns are put into the crushing cylinder 3 through the first feeding hopper 2; The crushing cylinder 3 is provided with a grinding shell 4, the grinding shell 4 is a hemispherical shell, and the grinding shell 4 is provided with uniformly distributed through holes; the grinding shell 4 is nested with a grinding ball 5, and the upper end of the grinding ball 5 is connected to a drive mechanism, the driving mechanism drives the grinding ball 5 to rotate up and down, and the grinding ball 5 cooperates with the grinding shell 4 to rotate and squeeze the pellet feed falling into...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is that: the lower part of the mixing box 1 is connected with a water-adding and discharging mechanism, and the water-adding and discharging mechanism includes a feeding pipe 25 and a discharging cylinder 28, and the feeding pipe 25 is connected with a discharging pipe through a communication groove 27. The material cylinder 28, the discharge tube 25 is provided with a spiral discharge roller 26, and the discharge cylinder 28 is provided with a spiral discharge roller 29, and the spiral discharge roller 29 extends to the outside of the discharge cylinder 28 and is connected with a second shaft coupling. The second motor 30 and the spiral unloading roller 26 extend to the bottom of the unloading pipe 25 and are connected and driven by the third transmission gear set 31 to the spiral unloading roller 29, thereby realizing unloading at a uniform speed.

[0028] The discharge cylinder 28 is connected with a hot water pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com