Raw material grinding equipment for ceramic membrane production

A raw material and ceramic membrane technology, which is applied in the field of raw material grinding equipment for ceramic membrane production, can solve the problems of high manpower and material resources, low grinding efficiency, and poor grinding effect, and achieve the effect of increasing operating efficiency, good grinding effect, and convenient stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

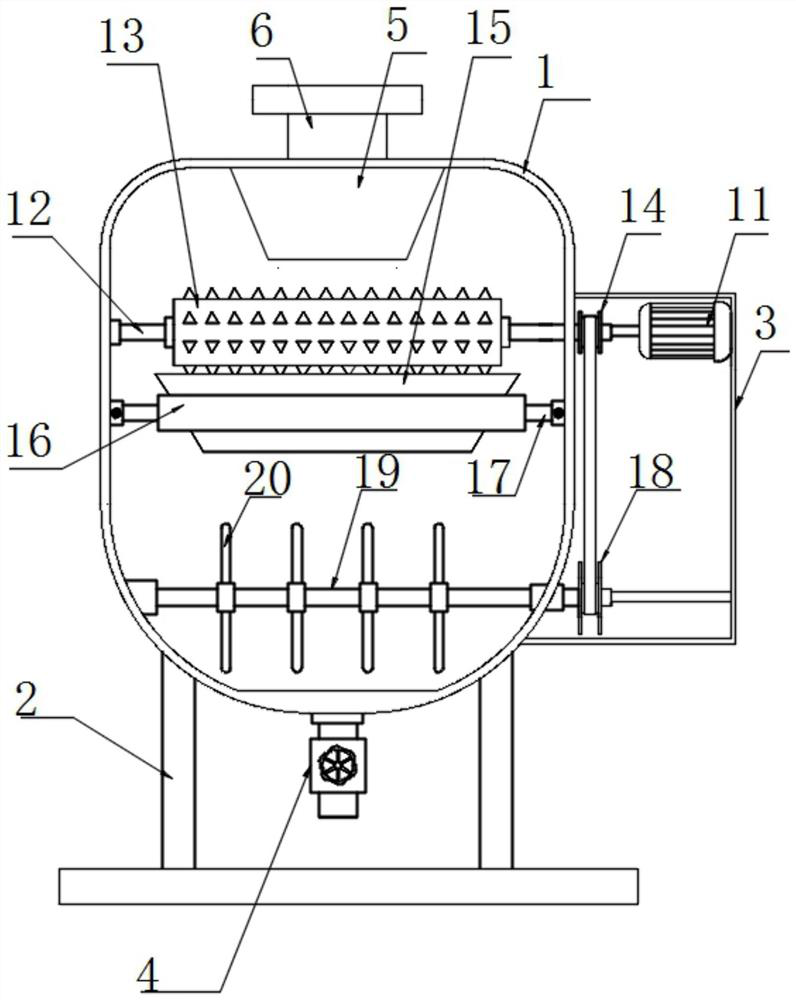

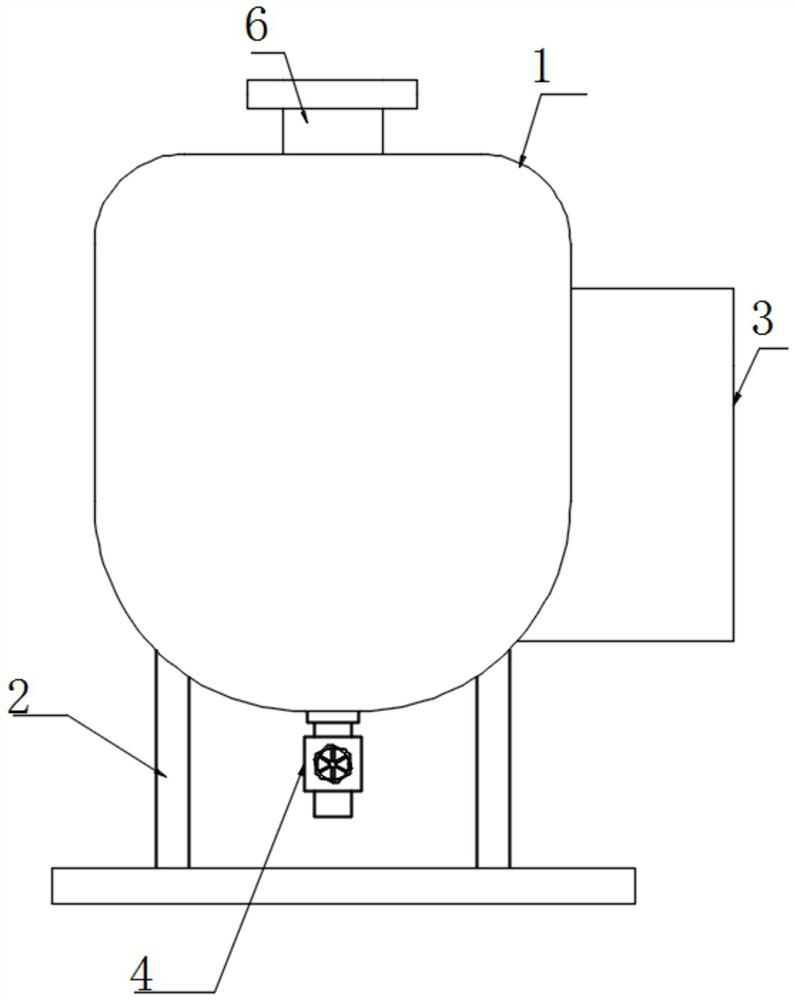

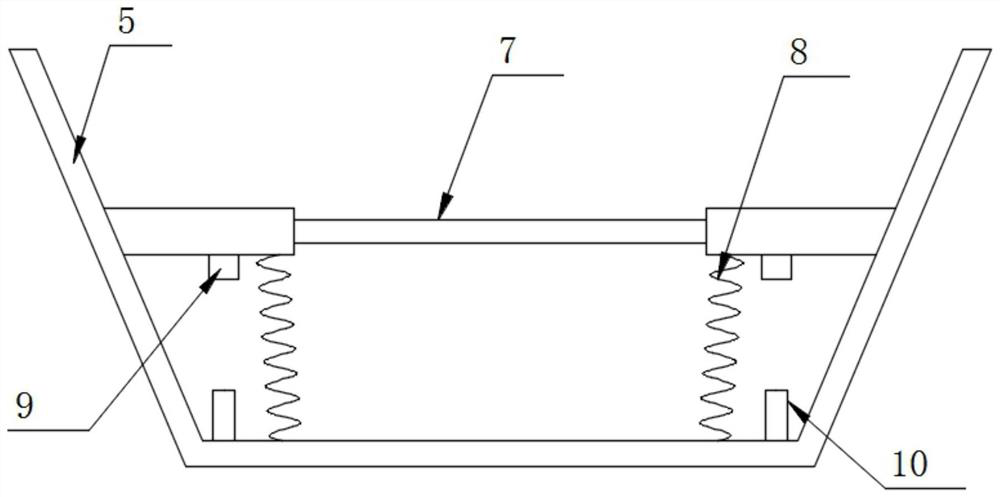

[0024] The embodiment is specifically: start the drive motor 11, pour the raw material into the quantitative box 5 through the feed pipe 6, the raw material falls on the solenoid valve 7, the solenoid valve 7 falls under the action of gravity, and finally the first electrode block 9 and the second electrode block The block 10 is in electrical contact, the valve of the electromagnetic valve 7 is opened, and then the raw material falls between the crushing rollers 13 to be crushed. It makes the amount of crushing uniform each time, the stirring is more sufficient, and the grinding effect is better.

[0025] The working principle of the present invention:

[0026] First close the motor box 4, then start the drive motor 11, pour raw materials into the quantitative box 5 through the feed pipe 6, the raw materials fall on the solenoid valve 7, the solenoid valve 7 falls under the action of gravity, and finally the first electrode block 9 and the second electrode block The two elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com