Flour extruding device for fried balls and ball frying device

An extrusion device and fabric technology, applied in oil/fat baking, food forming, food science, etc., can solve the problem of inconvenient use of meatball frying equipment, achieve easy cleaning and maintenance, high work efficiency, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] see Figure 1 to Figure 10 .

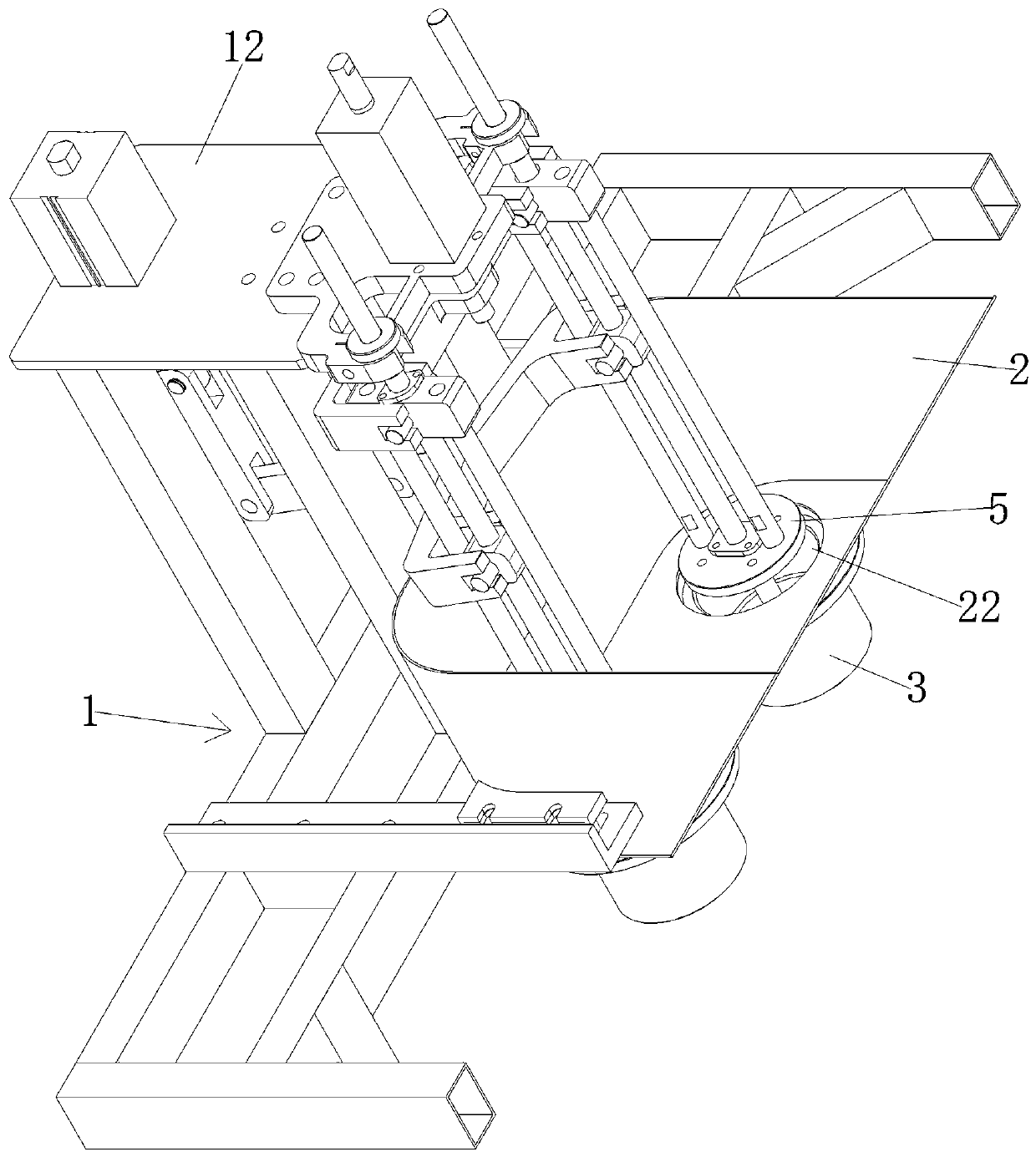

[0050] Such as figure 1 As shown, the fabric extruding device for deep-fried meatballs provided by the embodiment of the present invention includes a mounting frame 1 and a hopper 2, and the mounting frame 1 plays a supporting role. 1 is provided with two supporting angle steels 11, and the two sides of the hopper 2 are respectively provided with ear plates 21, and the ear plates 21 are fixed on the supporting angle steels 11 by bolts.

[0051] In this embodiment, the bottom surface of the hopper 2 is provided with two discharge ports 22, and the bottom of each discharge port 22 is provided with a cutting cylinder 3 to increase the speed of extruding the small fabric dough and improve the efficiency.

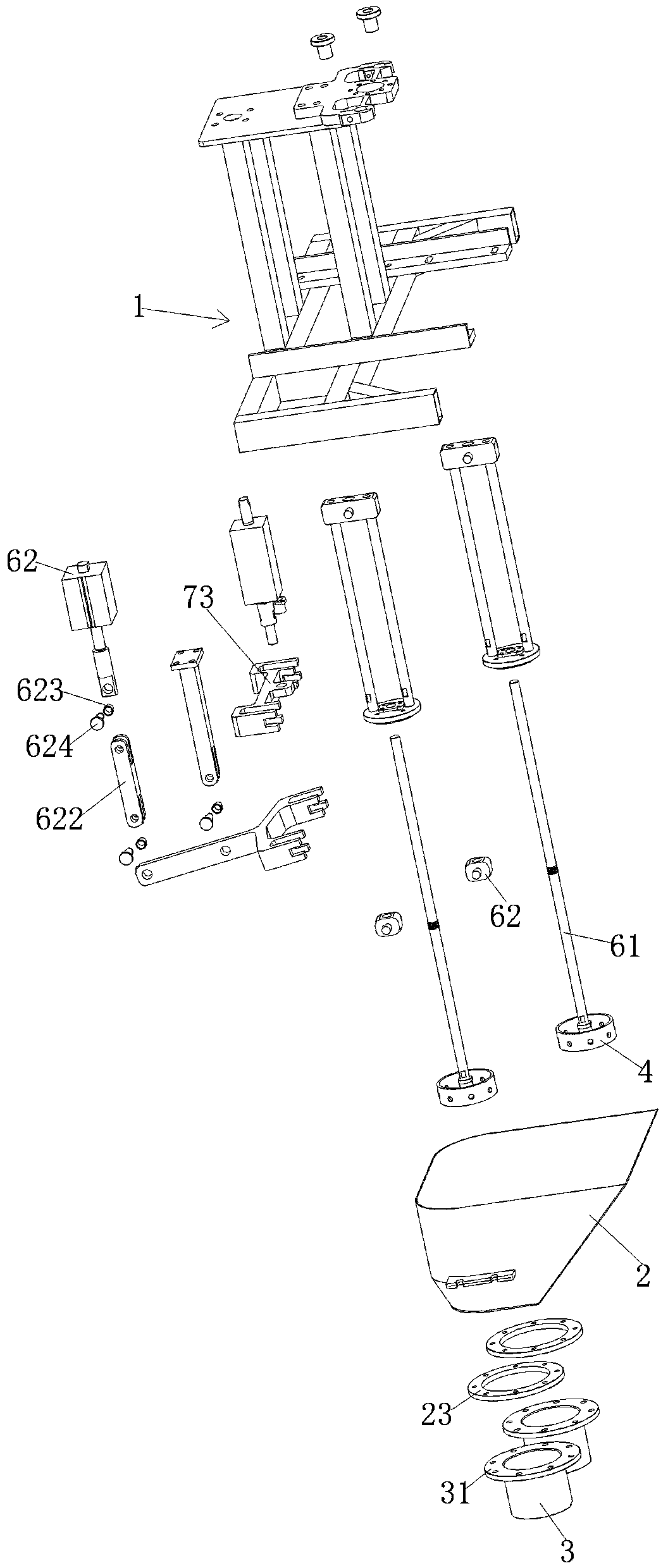

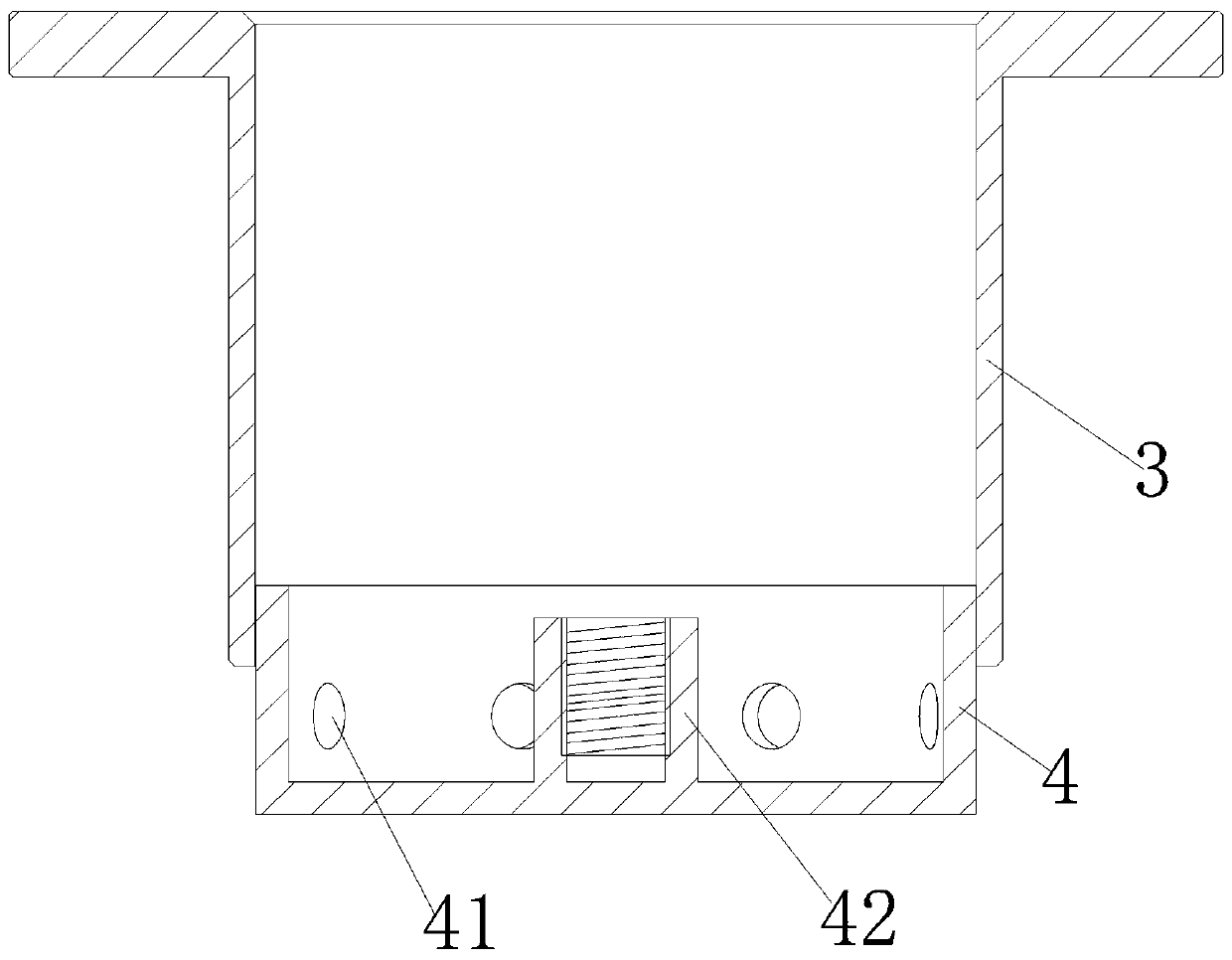

[0052] Such as figure 2 As shown, the lower surface of the hopper 2 is provided with an upper flange 23 corresponding to the position of the lower material opening 22, and the upper flange 23 is welded into one body with the lower surfac...

Embodiment 2

[0072] A kind of meatball frying equipment, please refer to Figure 11 .

[0073] Such as Figure 11 , the meatball frying equipment of the embodiment of the present invention comprises pan support 9, and the fabric extruding device of deep-fried meatball in embodiment 1, is provided with oil pan 91 on pan support 9, and the bottom of oil pan 91 is heated by electricity or gas Heating, a support frame 92 is provided at one end of the pan support 9, and the installation frame 1 of the fabric extruding device of fried meatballs is arranged on the support frame 92, and the fabric extruding device of this fried meatballs is positioned at the oil pan 91 tops. The fabric extruding device of the deep-fried balls above the oil pan 91 constantly extrudes the fabrics to become small fabric balls and falls into the oil pan to fry into balls.

[0074] Further, a slide rail 921 is provided on the support frame 92, and a slide block 14 is correspondingly provided at the bottom of the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com