Low-vacuum electrostatic flocking device

An electrostatic flocking and low-vacuum technology, which is applied in the direction of devices and coatings that apply liquid to the surface, can solve the problems of slow falling speed and affect the flocking effect, etc., to achieve simple and convenient operation, improve flocking efficiency, firm The effect of flocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

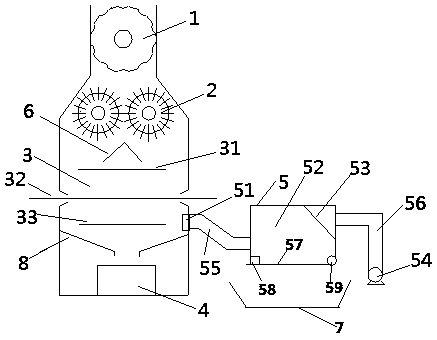

[0016] like figure 1 Shown, a kind of electrostatic flocking device comprises feed roller 1, bristle roller 2, flocking chamber 3 and surplus velvet collection box 4, and described low pressure mechanism 5 comprises air suction port 51, dust box 52, filter 53 and Mechanical pump 54; the surface of the feed roller 1 is evenly provided with feeding grooves, and the fluff falls on the bristle roller 2 through the groove, and the bristle roller 2 is two rollers that are the same in size and rotate at the same speed in the opposite direction, so that the fluff can be Fully break up; the broken fluff enters the flocking chamber 3 after passing through the splitter plate 6, and the flocking chamber 3 is externally connected to a low-pressure device 5, and the low-pressure device 5 makes the flocking chamber 3 in a low vacuum state by means of pumping air .

[0017] The flocking chamber 3 includes a negative plate 31, a yarn delivery area 32 and a positive plate 33, the yarn delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com