Soil remediation device

A technology of soil remediation and crushing device, which is applied in the field of soil remediation and can solve the problems of slow response, low remediation efficiency, uneven dosing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

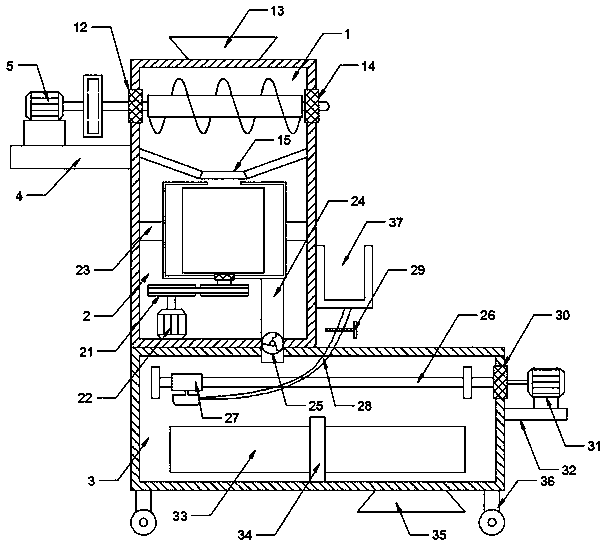

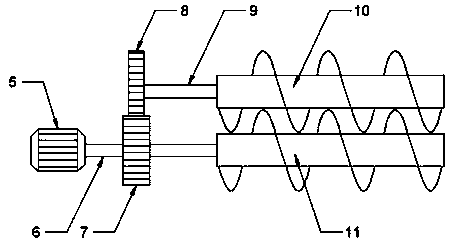

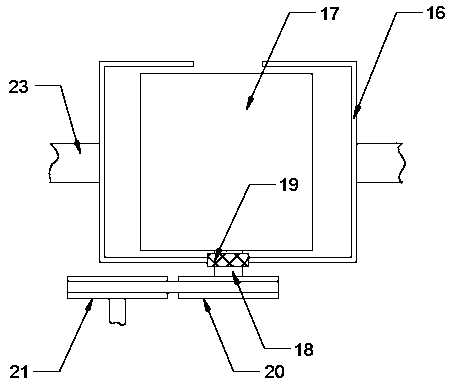

[0022] see Figure 1~3 , in an embodiment of the present invention, a soil remediation device includes a crushing device, a centrifugal device and a stirring device, the crushing device includes a crushing box 1, a second crushing roller 10 and a first crushing roller 11, the crushing box 1 The left outer wall is fixedly connected to the first support plate 4, the top of the first support plate 4 is fixedly connected to the first motor 5, and the output end of the first motor 5 is fixedly connected to the first rotating shaft 6, on which the first rotating shaft 6 The first gear 7 is fixedly socketed, and the first gear 7 and the second gear 8 are connected in transmission. The right end of the second gear 8 is fixedly connected to the second rotating shaft 9, and the right end of the first rotating shaft 6 is fixedly socketed on the first The crushing roller 11, the right end of the second rotating shaft 9 is fixedly sleeved with the second crushing roller 10, the second crus...

Embodiment 2

[0028] see Figure 4 , the present embodiment optimizes the bacteria storage box 37, the top of the right wall of the bacteria storage box 37 is fixedly connected to the strut 42, and the strut 42 is connected to the end cover 41 by hinge rotation, and the right end of the end cover 41 is fixedly connected Magnet 39, the right wall top of described bacteria storage box 37 is fixedly connected with iron block 40, the right side upper end of described pole 42 and the top middle part of described end cover 41 are respectively connected the two ends of spring 38, is provided with end cover 41 To prevent the preparation from being polluted, the provided magnet 39 and iron block 40 facilitate the opening and closing of the end cover 41 .

[0029] The electrical components appearing in this article are all connected with the external main controller and 220V mains electricity, and the main controller can be a conventional known device that plays a control such as a computer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com