Tundish flow control system capable of filtering inclusions in steel

A tundish and flow system technology, which is used in casting melt containers, manufacturing tools, metal processing equipment, etc., can solve problems such as clogging of flow control devices, and achieve the effects of preventing filter clogging, improving continuity and efficiency, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

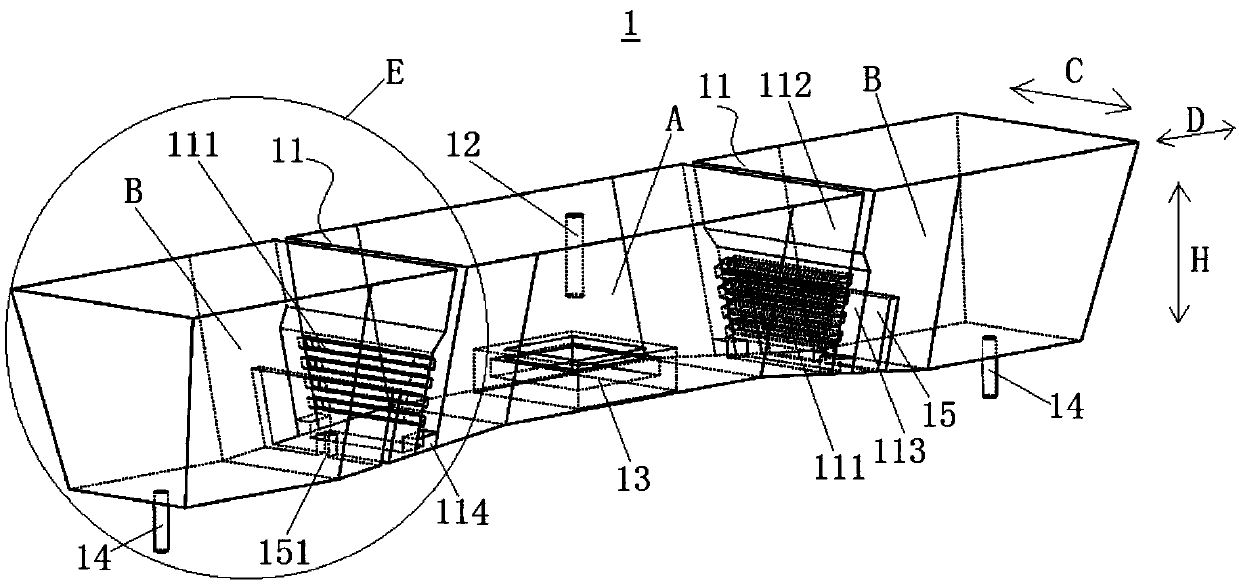

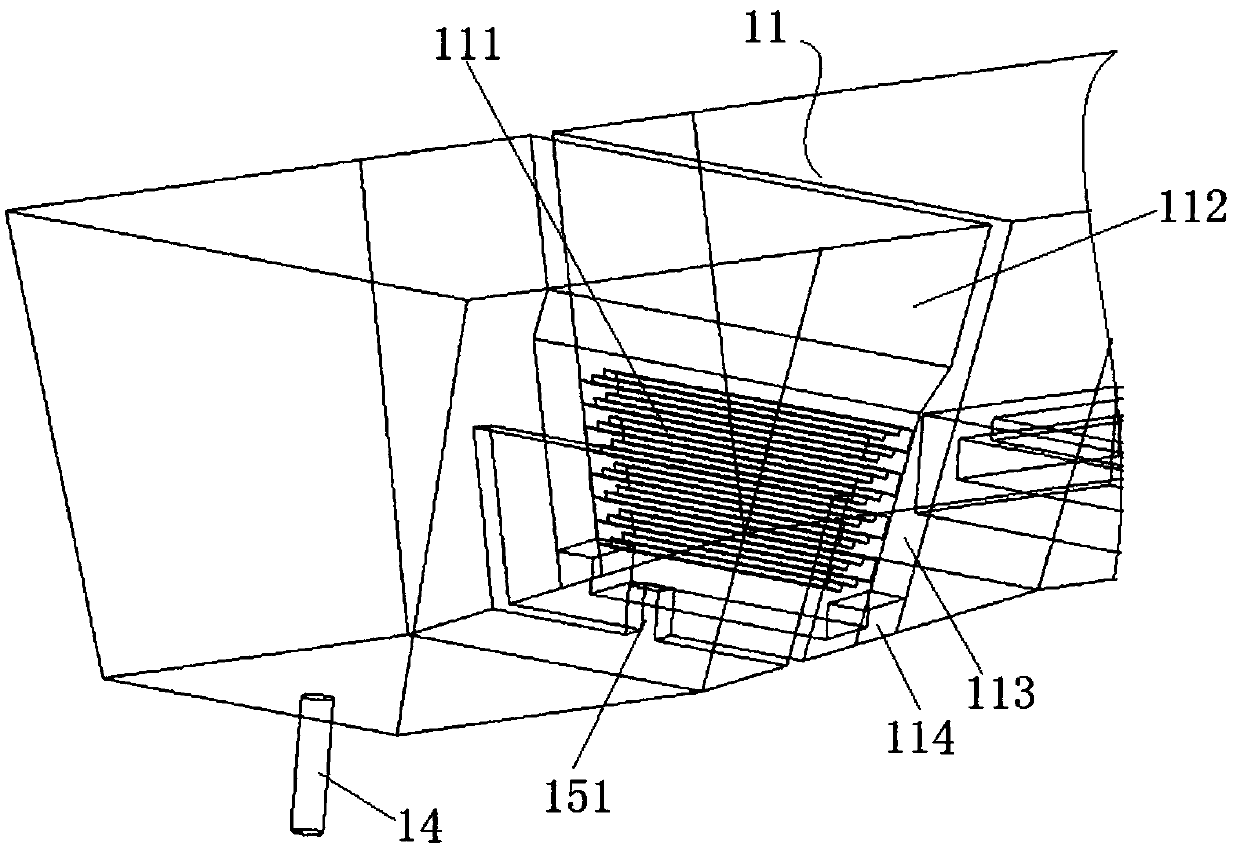

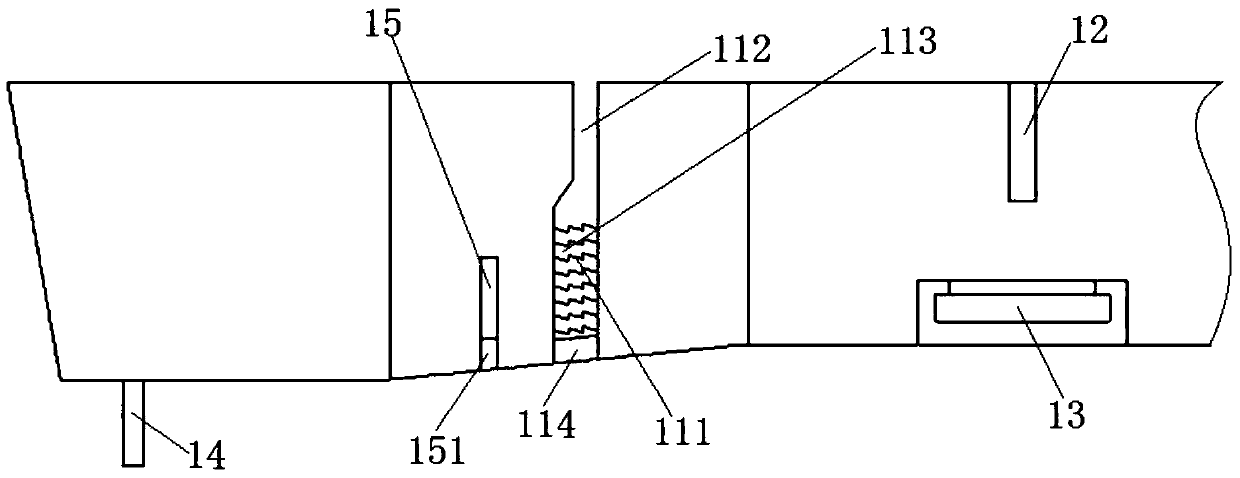

[0031] The tundish flow control system capable of filtering inclusions in steel of embodiment 1, its specific structure is as follows figure 1 shown. Comparative example 1 is a conventional tundish in the prior art.

[0032] According to the flow state of molten steel in the tundish, the inner space of the tundish can be divided into: mixing zone, piston zone and dead zone. The mixing zone is located near the injection flow of the ladle, and the molten steel is mixed with the injection flow from the ladle; the piston zone is generated between the mixing zone and the water outlet, and the fluid in this zone pushes forward and flows with partial back mixing; the dead zone Adjacent to the piston area, the fluid in this area exchanges slowly with the outside world. The ideal tundish structure and corresponding flow control technology should be able to create as large a piston area as possible and as small a dead area as possible.

[0033]Since the fluid flow in the tundish belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com