An adjustable protection device applied to blade finishing

A protection device and blade technology, which is applied to used abrasive treatment devices, abrasives, metal processing equipment, etc., can solve the problem that the gap between the intake and exhaust edges cannot be adjusted, the quality of the intake and exhaust edges is poor, and the parts are damaged. problems, to achieve the effect of improving processing quality, eliminating positioning gaps, and optimizing the linear speed of abrasive grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

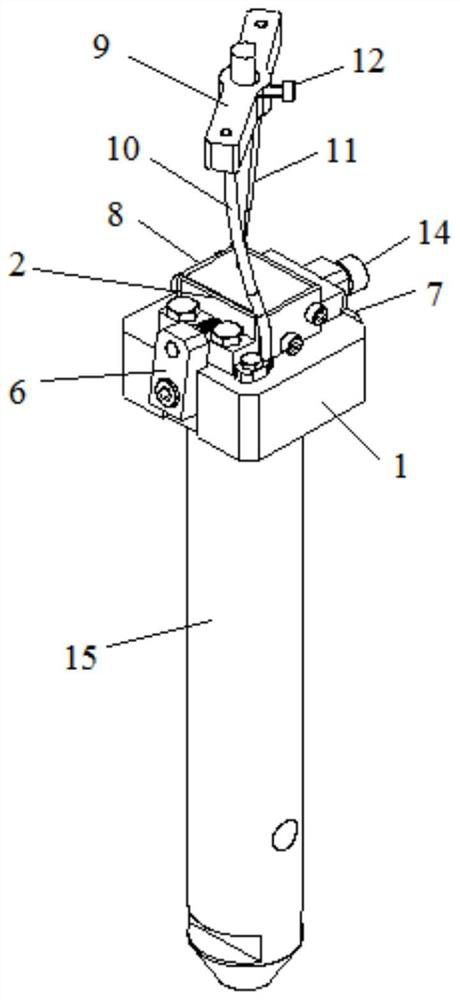

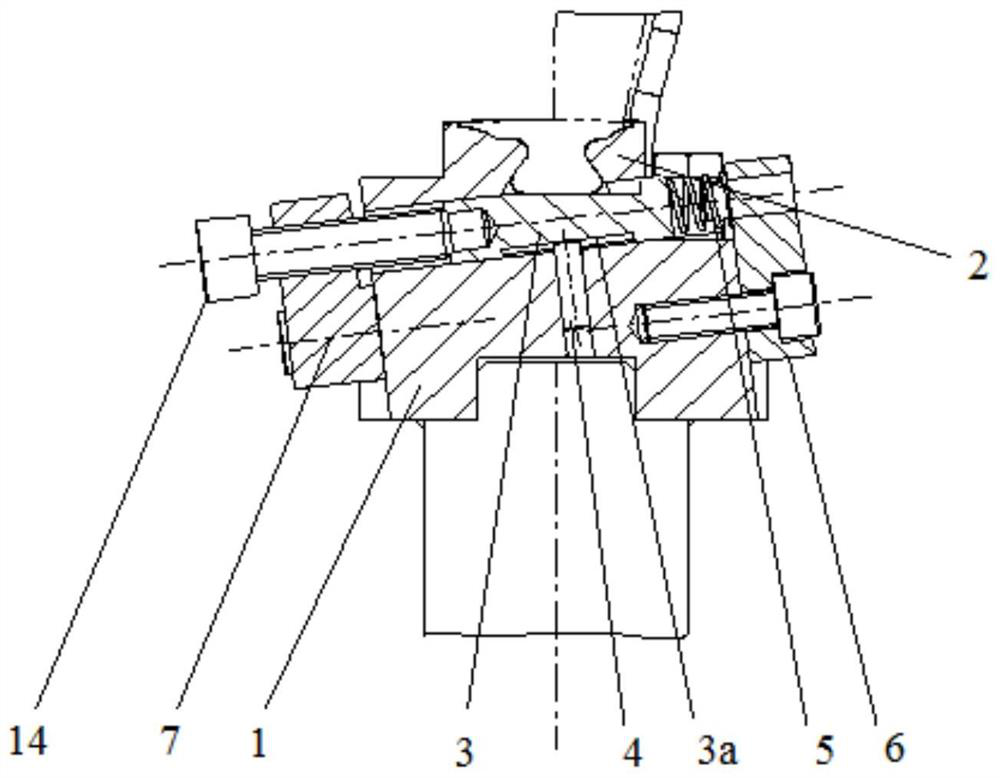

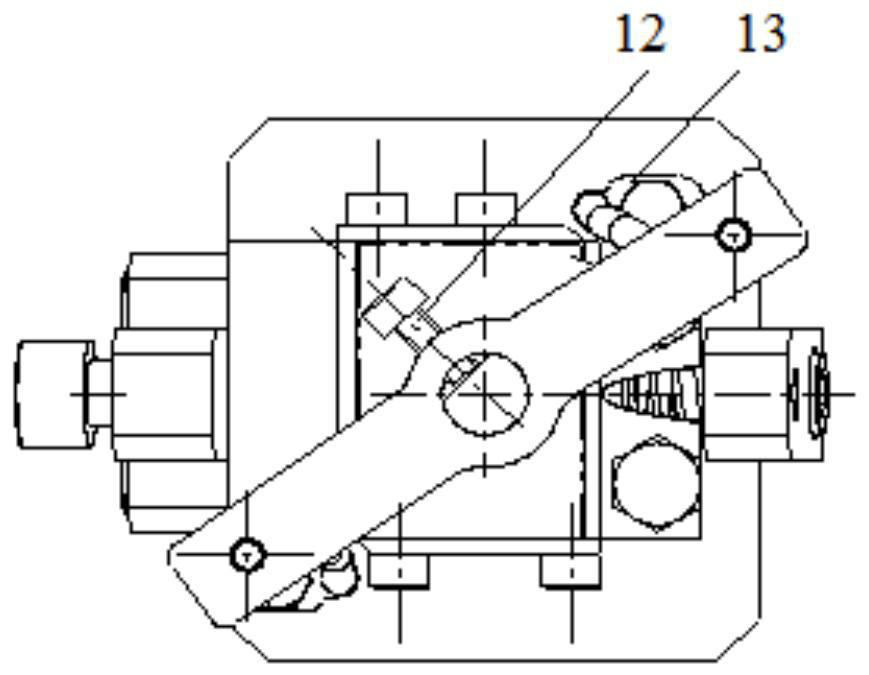

[0020] Such as Figure 1-6 As shown, an adjustable protection device applied to blade finishing, including: base 1, positioning block 2, ejector pin 3, guide post 4, spring 5, support plate I6, support 7, baffle plate 8, support plate Ⅱ9. Exhaust side bar 10, intake side bar 11, jacking bolt Ⅰ12, adjusting piece 13, jacking bolt Ⅱ14, mandrel 15, bolt 16;

[0021] The mandrel 15 is welded to the lower part of the base 1, and the left and right sides of the upper part of the base 1 are provided with inclined-plane through holes that are high on the right and low on the left. The support plate I6 is fixed on the right side of the base 1, and the support 7 is fixed on the left side of the base 1. From right to left, there are spring 5, jacking pin 3 and jacking bolt II14 in sequence. The right side of spring 5 is fixed on support plate I6, and jacking bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com