Three-dimensional paster processing method

A processing method and sticker technology, applied in the field of sticker processing, can solve the problems of slow forming, product deformation, difficult demoulding, etc., and achieve the effect of saving driving resources, good forming effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

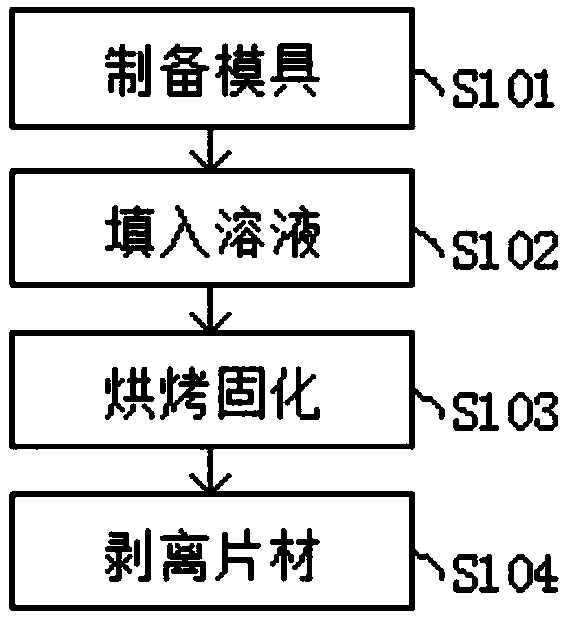

[0032] Embodiments of the present invention provide a three-dimensional sticker processing method, such as figure 1 shown, including the following steps:

[0033] Step S101: Prepare a mold

[0034] Select the metal plate to be engraved, and engrave the cavity and the liquid storage tank on the surface of the metal plate to obtain the mold; the cavity matches the pattern of the three-dimensional sticker; the liquid storage tank is used to store the PVC solution overflowing from each cavity.

[0035] Step S102: Filling in the solution

[0036] Fill the mold with PVC solution until the bottom of the reservoir on the mold is filled.

[0037] Step S103: baking and curing

[0038] Bake the mold filled with the PVC solution until the PVC solution on the mold solidifies into a PVC sheet.

[0039] Step S104: peeling off the sheet

[0040] After the PVC solution on the mold solidifies into a patterned PVC sheet, the PVC sheet is peeled off.

[0041] Using the processing method pro...

Embodiment 2

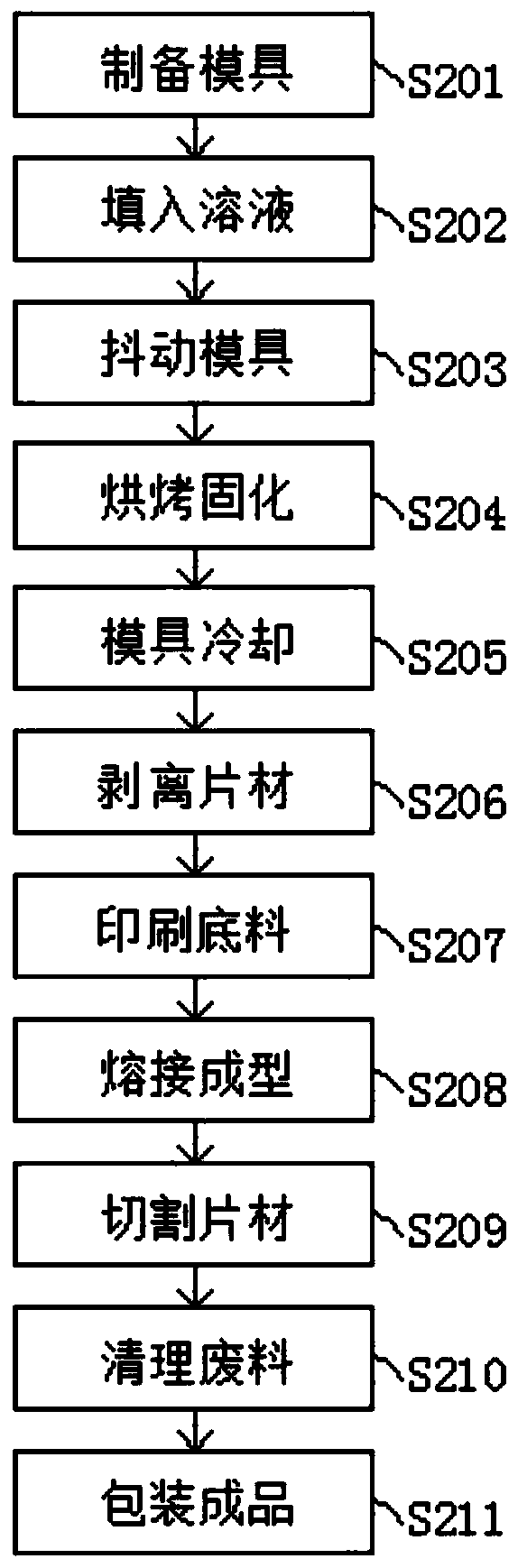

[0043] Embodiments of the present invention provide a three-dimensional sticker processing method, such as figure 2 shown, including the following steps:

[0044] Step S201: Prepare the mold

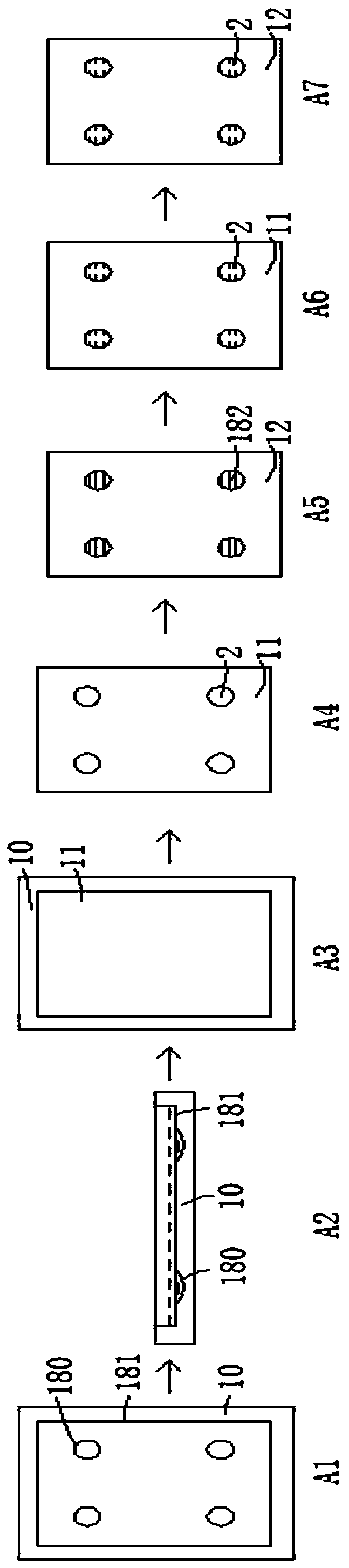

[0045] Select the metal plate to be engraved, and after engraving the cavity 180 and the liquid storage tank 181 on the surface of the metal plate, the mold 10 is obtained; the cavity 180 matches the three-dimensional sticker pattern 2; the liquid storage tank 181 is used to store the overflow from each cavity 180 PVC solution.

[0046] In this embodiment, the design color picture of the three-dimensional sticker pattern is converted into a 3D relief effect picture, and then the metal plate can be carved according to the 3D relief file to make a mold. Preferably, JD software can be used to make 3D relief files, and a fine engraving machine can be used to engrave copper molds.

[0047] Step S202: Filling in the solution

[0048] Fill the PVC solution into the mold 10 until the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com