Automobile crawler belt anti-skid device

An anti-skid device and crawler technology, which is applied in anti-skid devices, vehicle parts, transportation and packaging, etc., can solve the problems of small contact area, difficulty in preventing slipping, and lack of anti-skid effect, so as to achieve good contact area, prevent automobile skidding, The effect of flexible and practical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

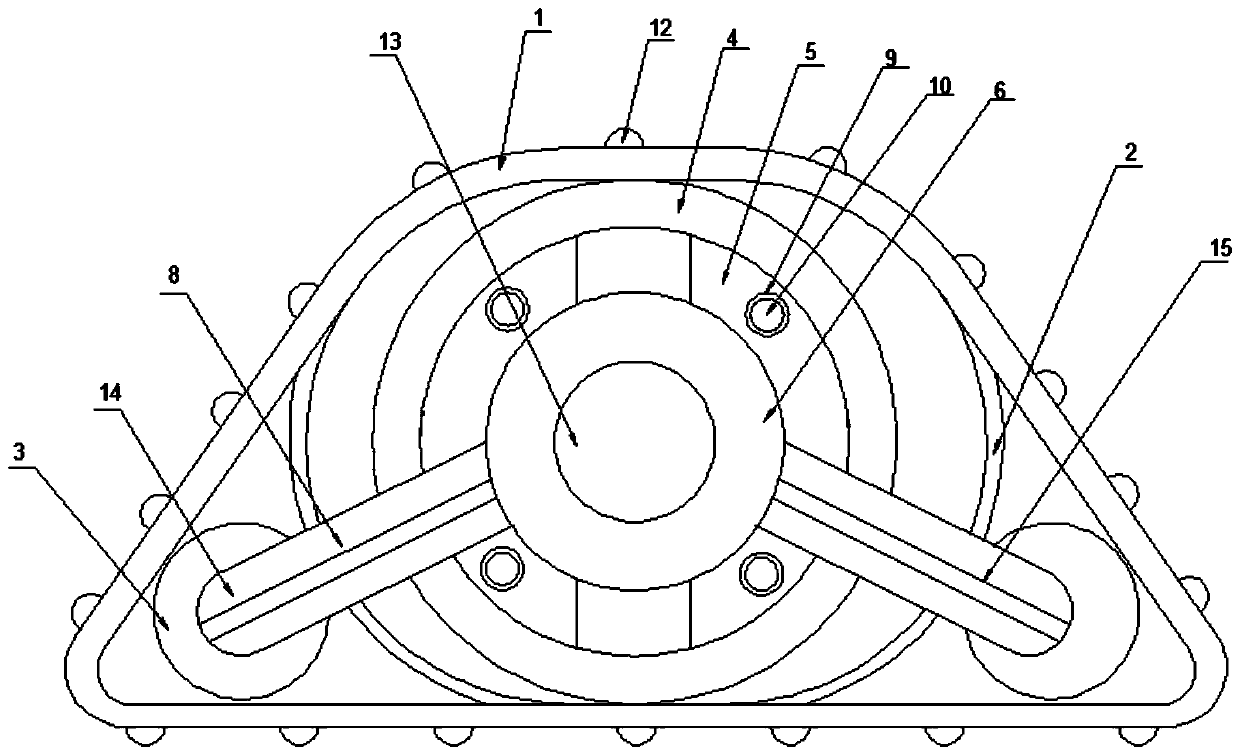

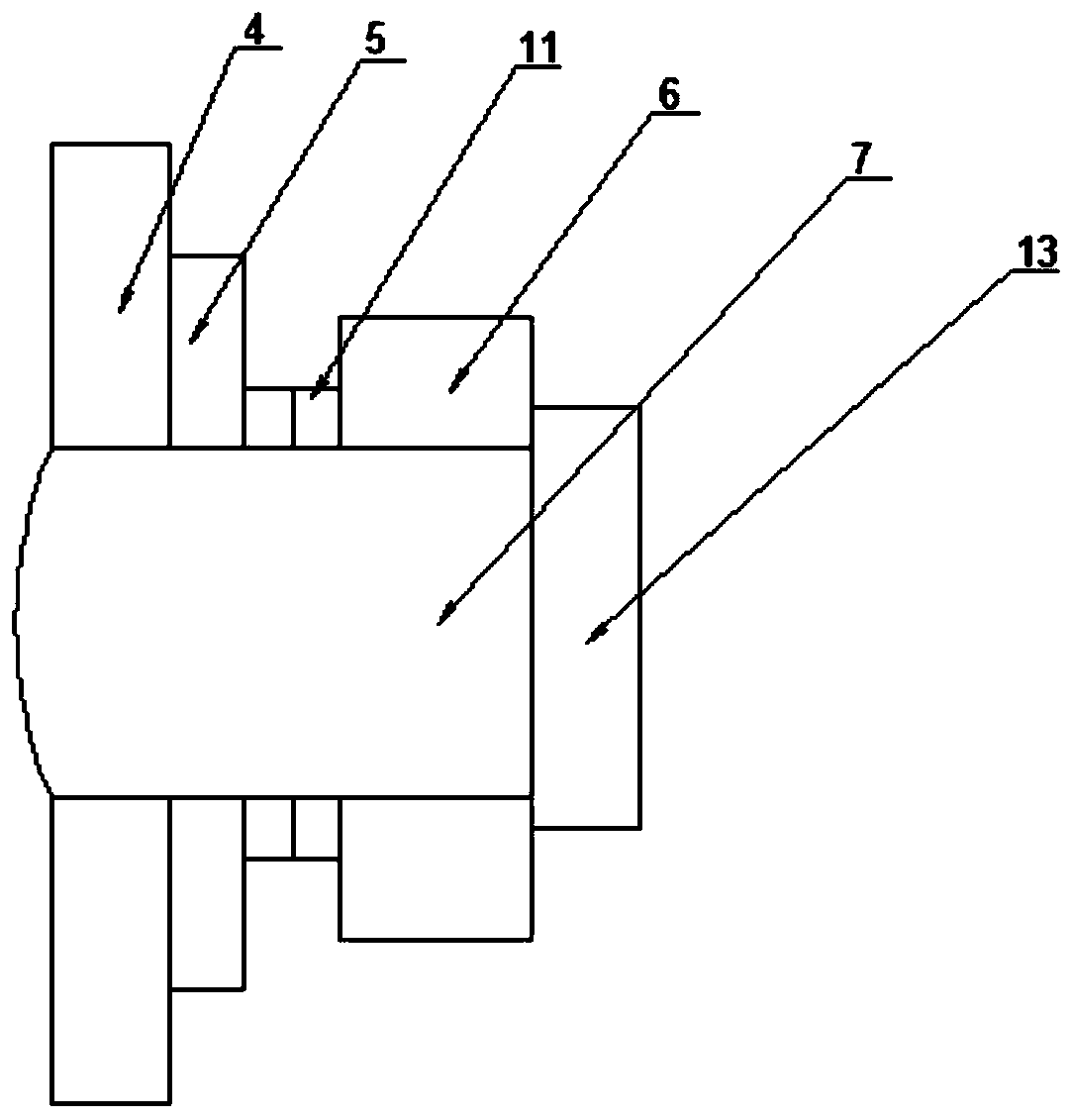

[0022] Such as Figure 1-2 As shown, the automobile crawler anti-skid device according to the embodiment of the present invention includes an anti-skid crawler 1, and both sides of the anti-skid crawler 1 are respectively provided with supporting seats 2 matched with it, and the inside of the supporting seat 2 is provided with The matching shaft 3 of the non-slip crawler 1, the middle position inside the non-slip crawler 1 is symmetrically provided with a mounting plate 4, and the side of the mounting plate 4 away from the non-slip crawler 1 is provided with a fixed plate matching it 5. The side of the fixed plate 5 far away from the anti-slip track 1 is provided with an axis fixing frame 6, and the side of the axis fixing frame 6 close to the anti-skid track 1 is provided with a The fixed bearing rod 7 is fixed, and the two sides of the shaft center fixing frame 6 are respectively provided with matching frames 8 matched with the matching shaft 3 .

[0023] Let's talk about t...

Embodiment 2

[0026] Such as Figure 1-2 As shown, the interior of the fixed plate 5 is provided with a number of evenly distributed fixed holes 9, the interior of the fixed holes 9 is provided with fixed pins 10, and the shaft center bracket 6 and the fixed plate 5 are provided with Connect the bearing ring 11, the outer wall of the non-slip track 1 is provided with a number of uniformly distributed protective bumps 12, the end of the fixed bearing rod 7 away from the anti-slip track 1 is provided with a protective fixed ring 13, the matching frame 8 and A connecting bearing plate 14 is provided between the matching shafts 3, and an identification reflective strip 15 is provided on the outer wall of the matching frame 8. It is not difficult to see from the above design that the connecting bearing ring 11 can be bumped and shaken, causing the equipment to move to both sides. slippage phenomenon.

[0027] In order to facilitate the understanding of the above-mentioned technical solution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com