A kind of insulating and heat-conducting material for semiconductor and preparation method thereof

A technology of insulation and heat conduction, heat conduction and insulation fillers, applied in the direction of heat exchange materials, insulators, organic insulators, etc., can solve the problems of difficulty in ensuring the insulation of composite materials, damage to the insulation performance of composite materials, and difficulty in application, etc., to achieve high thermal conductivity, Improve heat dissipation efficiency and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

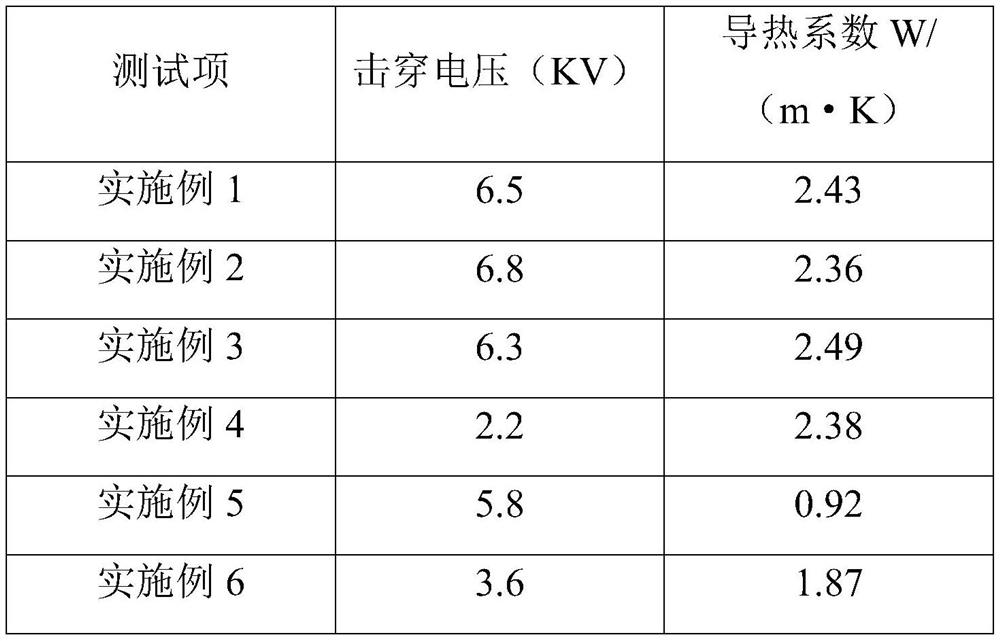

Examples

Embodiment 1

[0021] According to the weight of the weight, 60 parts of the thermoplastic resin, 10 parts of dispersing agent, 15 parts of adhesive, 9 expanded graphite and 12 bubble powder were prepared, and the semiconductor was prepared in the following method:

[0022] (1) In the adhesive, the expanded graphite and the sea bubble powder are added to the adhesive, and the mixture is mixed after mixing.

[0023] (2) The thermoplastic resin and dispersing agent, the curing agent are added to the mixture obtained from step (1), and the insulative thermally conductive material for the semiconductor is obtained at 100 to 160 ° C.

[0024] Among them, the thermoplastic resin is polymethyl methacrylate, the dispersant is polyvinylpyrrolidone, and the adhesive is a polystyrene adhesive and acetate adhesive, polystyrene adhesive and ethyl acetate. The mass ratio of the adhesive is 2: 5.

Embodiment 2

[0026] According to the weight of the weight, 50 parts of the thermoplastic resin, 7 parts dispersants, 10 parts of adhesives, 6 expanded graphite and 8 seafubi powder were prepared, and the semiconductor was prepared in the following method:

[0027] (1) In the adhesive, the expanded graphite and the sea bubble powder are added to the adhesive, and the mixture is mixed after mixing.

[0028] (2) The thermoplastic resin and dispersing agent, the curing agent are added to the mixture obtained from step (1), and the insulative thermally conductive material for the semiconductor is obtained at 100 to 160 ° C.

[0029] Among them, the thermoplastic resin is a polyamide, the dispersant is polyoxyethylene ether methacrylate, and the adhesive is a polystyrene adhesive and acetate adhesive, polystyrene adhesive and acetate The mass ratio of the ester adhesive is 1: 3.

Embodiment 3

[0031] According to the weight of the weight, 70 thermoplastic resins, 13 parts dispersants, 20 partial adhesives, 13 expanded graphite and 15 semibubic powder were prepared, and the semiconductor was prepared as described below:

[0032] (1) In the adhesive, the expanded graphite and the sea bubble powder are added to the adhesive, and the mixture is mixed after mixing.

[0033] (2) The thermoplastic resin and dispersant are added to the mixture obtained from step (1), and the curing agent is added to obtain a semiconductor insulated thermally conductive material in 100 to 160 ° C.

[0034] Among them, the thermoplastic resin is polyphenylene ether, the dispersant as polyoxyethylene ether acrylate, adhesive is a polystyrene adhesive and acetate adhesive, polystyrene adhesive and acetic acid The mass ratio of ethyl adhesive is 1: 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com