Automatic exhaust device of hydraulic circuit breaker

A hydraulic circuit breaker and automatic exhaust technology, which is applied to valve devices, machines/engines, liquid fuel engines, etc., can solve problems such as unsatisfactory exhaust effects, achieve simple installation, good sealing effect, and avoid cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

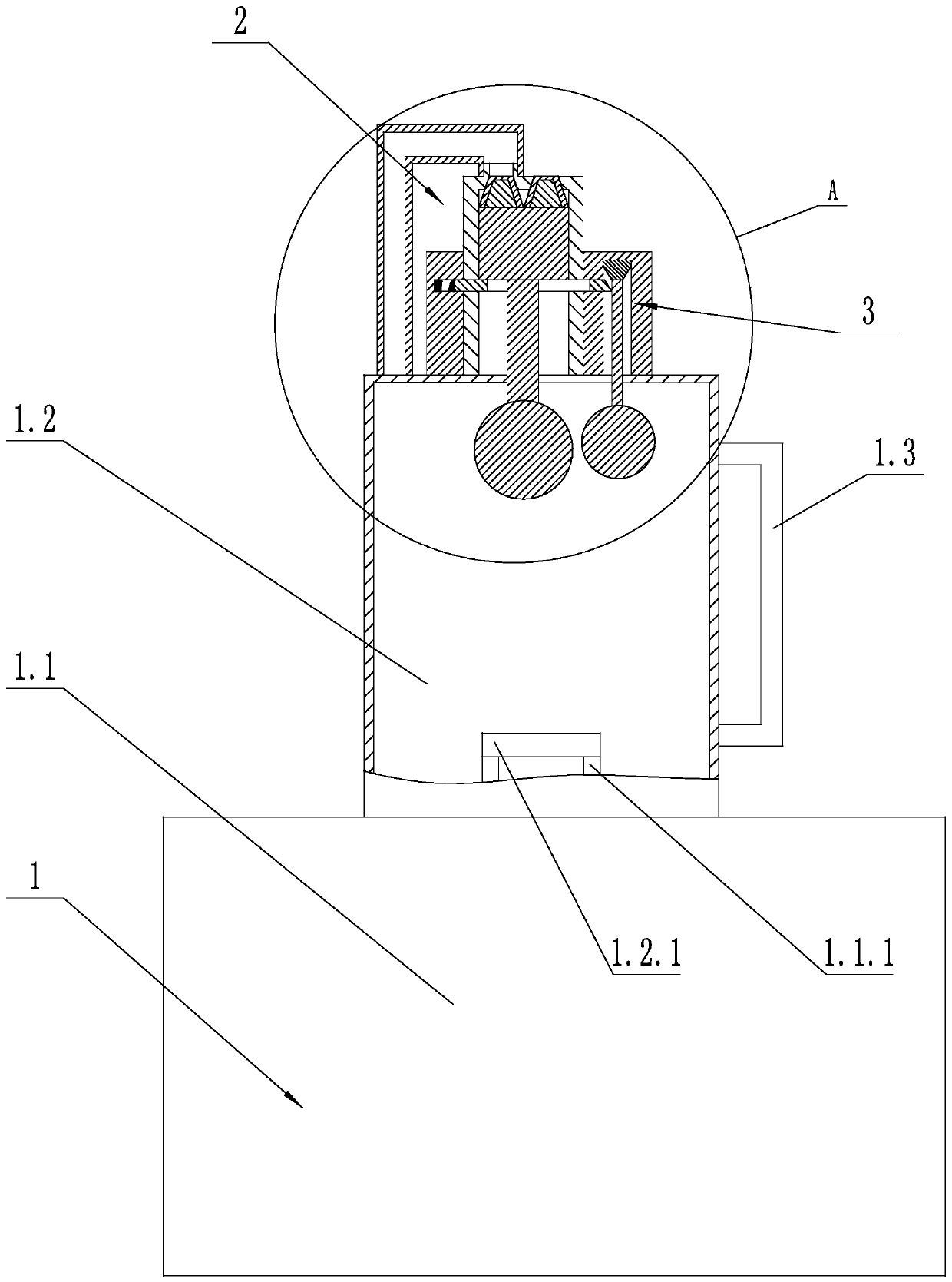

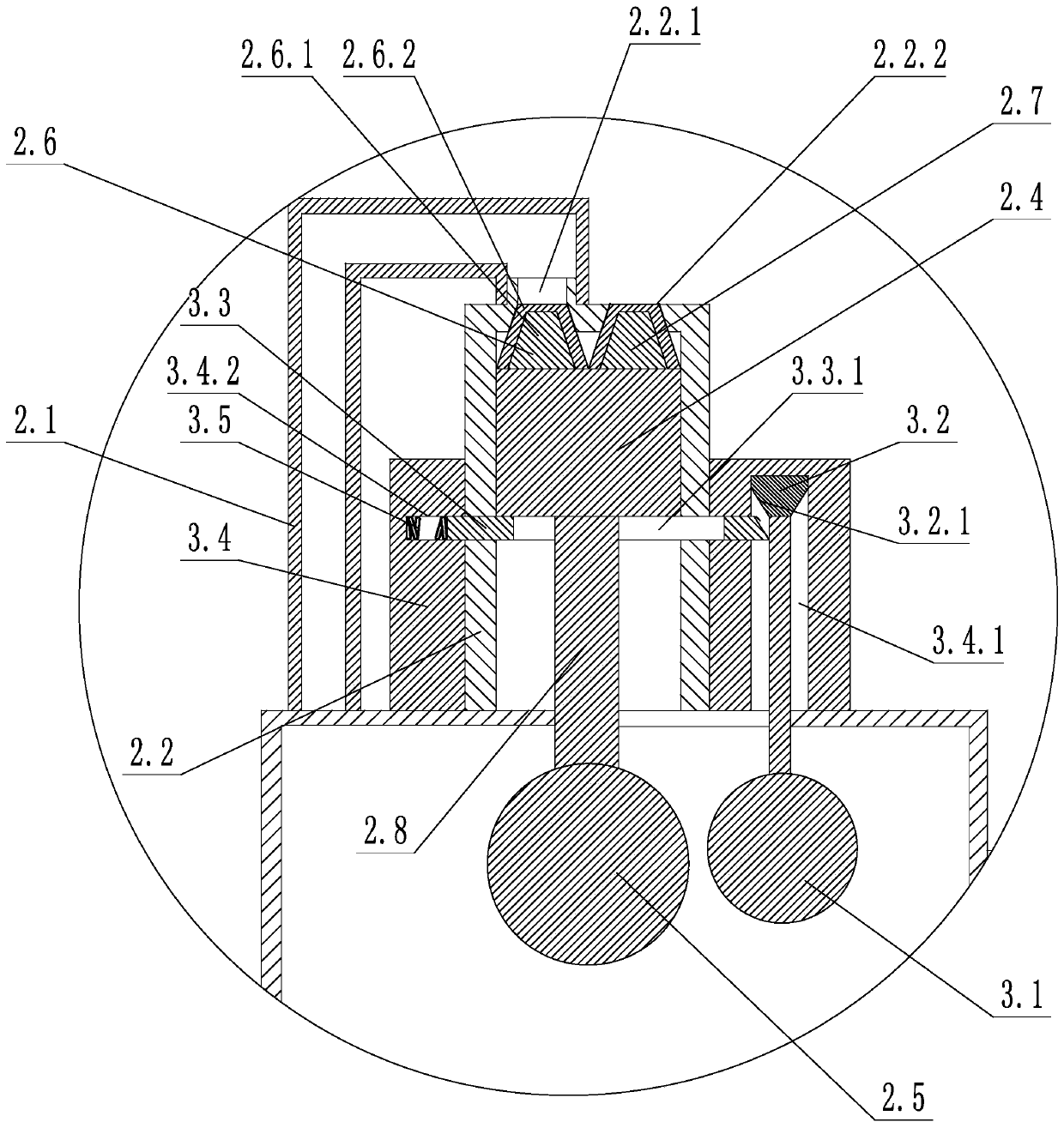

[0030] Such as figure 1 and figure 2 As shown, an automatic exhaust device for a hydraulic circuit breaker includes an oil pump 1. The oil pump 1 includes a pump body 1.1 and an air collecting tank 1.2. The air collecting tank 1.2 is arranged on the top of the pump body 1.1. .1, the bottom of the gas collecting tank 1.2 is provided with an internally threaded hole 1.2.1 adapted to the externally threaded pipe 1.1.1, and the gas collecting tank 1.2 communicates with the pump body 1.1 through the externally threaded pipe 1.1.1, the gas collecting tank 1.2 There is a liquid level display tube 1.3 on the outside; an exhaust assembly 2 is provided above the gas collection tank 1.2, and the exhaust assembly 2 includes an intake pipe 2.1, a connecting pipe 2.2, a slider 2.4 and a first floating ball 2.5;

[0031] The upper end of the connecting pipe 2.2 is provided with an air inlet 2.2.1 and an air outlet 2.2.2, the lower end of the connecting pipe 2.2 communicates with the gas co...

Embodiment 2

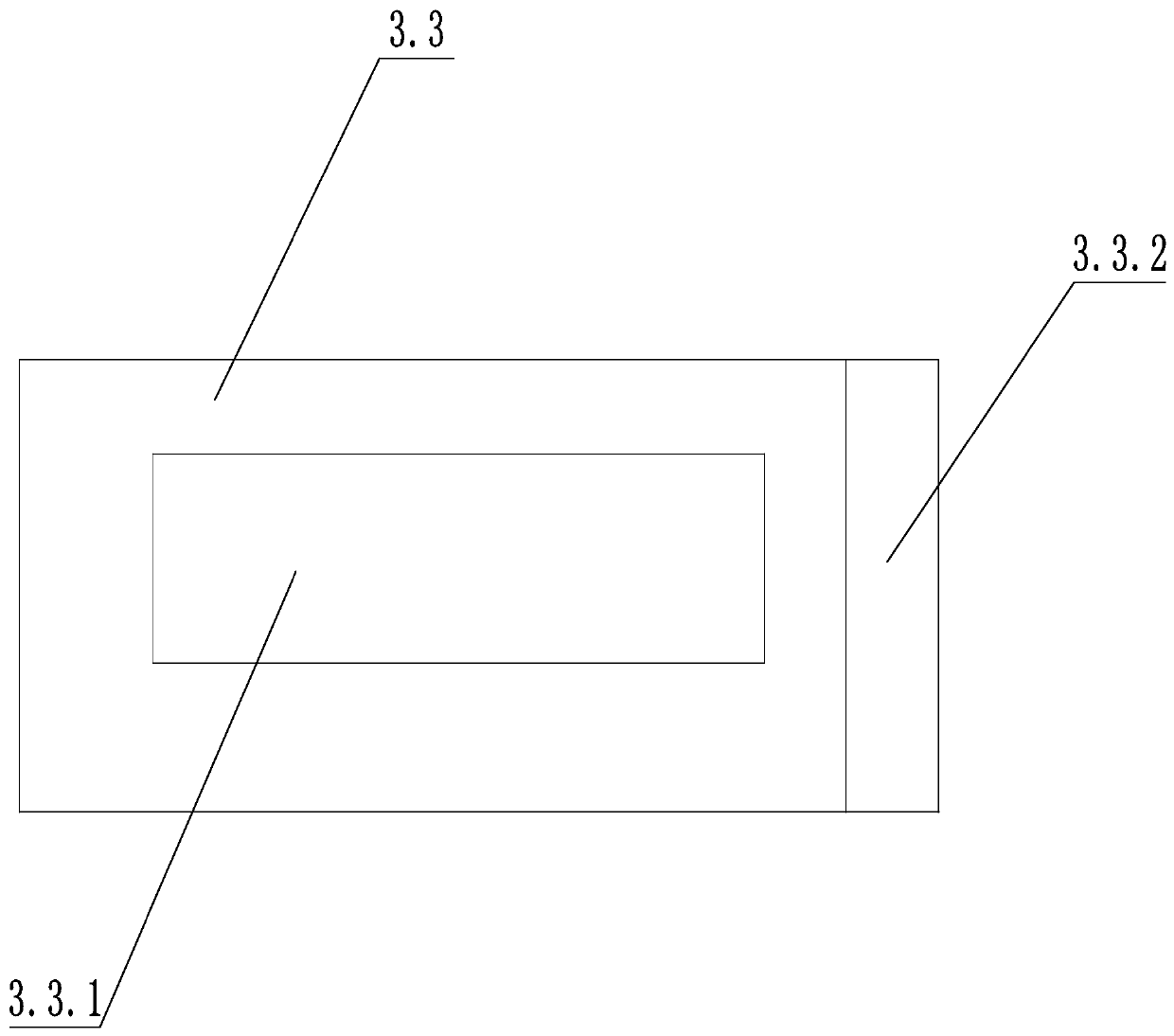

[0035] Such as figure 2 and image 3 As shown, on the basis of Embodiment 1, a hysteresis assembly 3 is also included, and the hysteresis assembly 3 includes a second floating ball 3.1, an unlocking block 3.2, a locking block 3.3, a fixed block 3.4 and a telescopic spring 3.5, and the fixed block 3.4 is provided with The first chute 3.4.1 and the second chute 3.4.2 communicate with each other, the first chute 3.4.1 is vertically arranged, and the unlocking block 3.2 is slidably arranged on the first chute 3.4.1; the second chute 3.4.2 Horizontal setting, the locking block 3.3 is slidably set in the second chute 3.4.2, the telescopic spring 3.5 is set in the second chute 3.4.2, and one end of the telescopic spring 3.5 is connected with the locking block 3.3, stretching The other end of the spring 3.5 is connected with the fixed block 3.4, the second chute 3.4.2 is connected with the connecting pipe 2.2, the locking block 3.3 is provided with an avoidance groove 3.3.1, and the...

Embodiment 3

[0038] Such as Figure 4 As shown, on the basis of Embodiment 2, when the slider 2.4 is lowered to the lowest position, the sliding side is still in contact with the locking block 3.3. The structure can ensure that the locking block 3.3 will not protrude after the slide block 2.4 descends, and ensure that the slide block 2.4 can move up and down freely before returning to the sealing position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com