Termination assembly

A termination and assembly technology, applied in the direction of pipes/pipe joints/fittings, pipe components, electrical components, etc., to solve problems such as unbalanced load transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

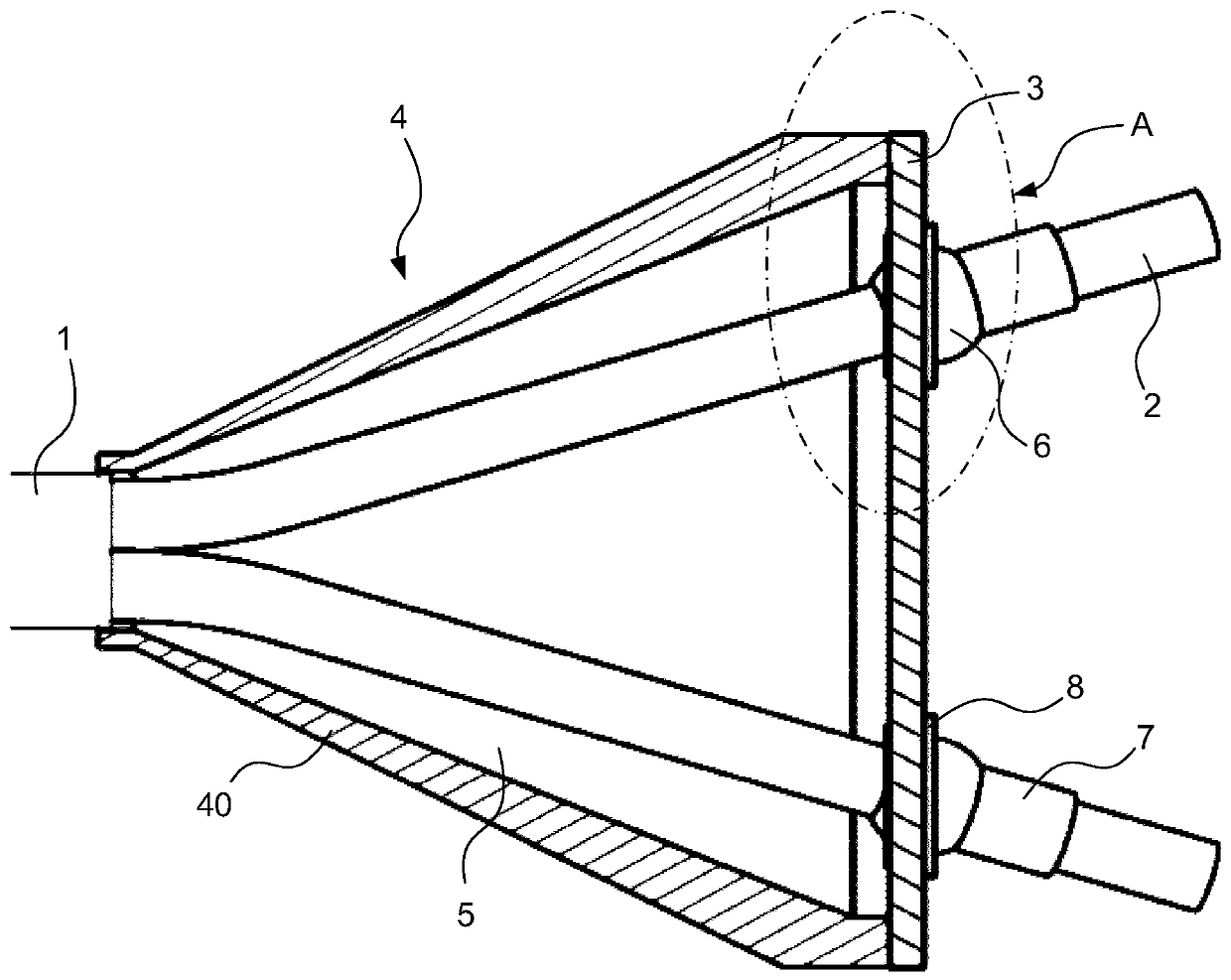

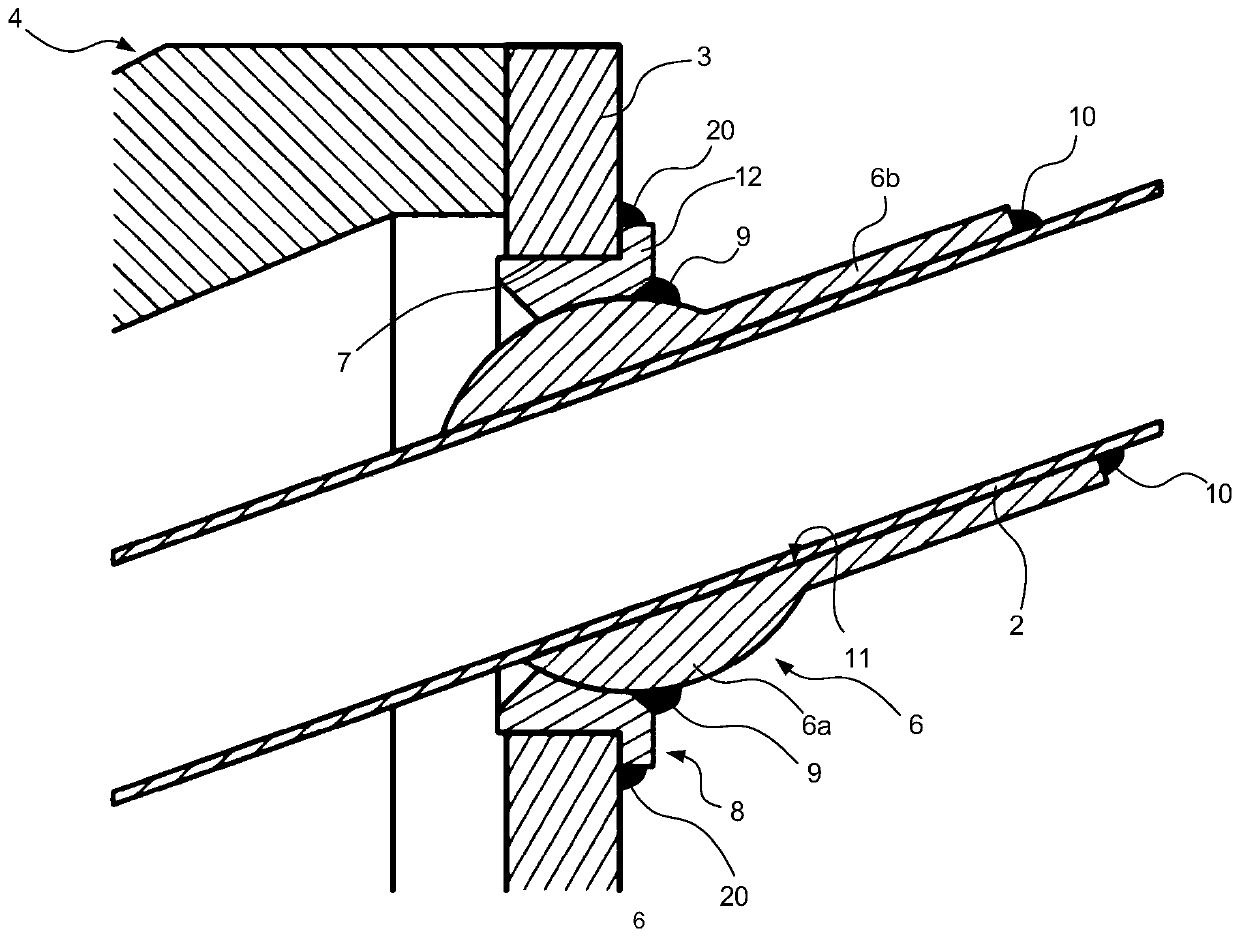

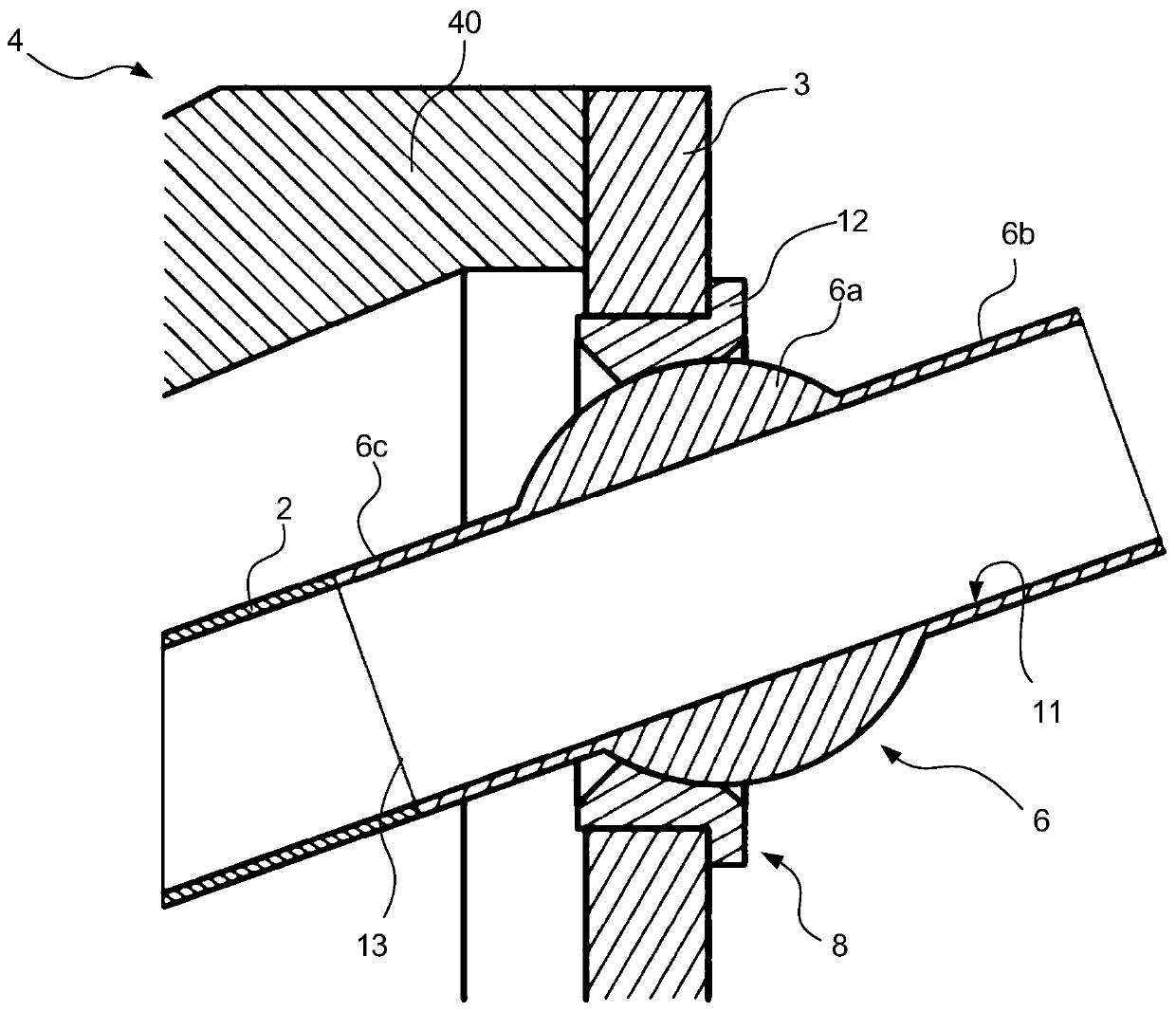

[0031] figure 1An embodiment of a termination assembly 4 for an umbilical 1 according to the invention is shown. In this embodiment, the termination assembly 4 comprises a plurality of umbilical elements, however only two steel pipes 2 are shown in the figure. The pipe 2 extends from the umbilical 1 through the termination cavity 5 of the termination assembly 4 and through corresponding holes in the steel bulkhead plate 3 . Additional umbilical elements will also pass through the bulkhead plate 3 . The bulkhead plate 3 is fixed on the terminal assembly 4 to form a terminal cavity 5 . In the arrangement shown, the conical pot portion 40 forming the body of the termination assembly 4 may be formed in multiple parts connectable together.

[0032] from figure 1 It can be seen that the steel pipe 2 is bent at a slight angle close to the end of the umbilical 1, but is relatively straight. As such, minimal machining of the tube is required to form the termination assembly. This...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com