Carbon Fiber Composite Fragile Cover

A composite material and fragile cover technology, applied in the direction of launching devices, etc., can solve the problems of difficult control of quality stability, large number of woven fabric layers, and large separation area range, achieving light weight, good overall performance, and improved resistance. The effect of bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

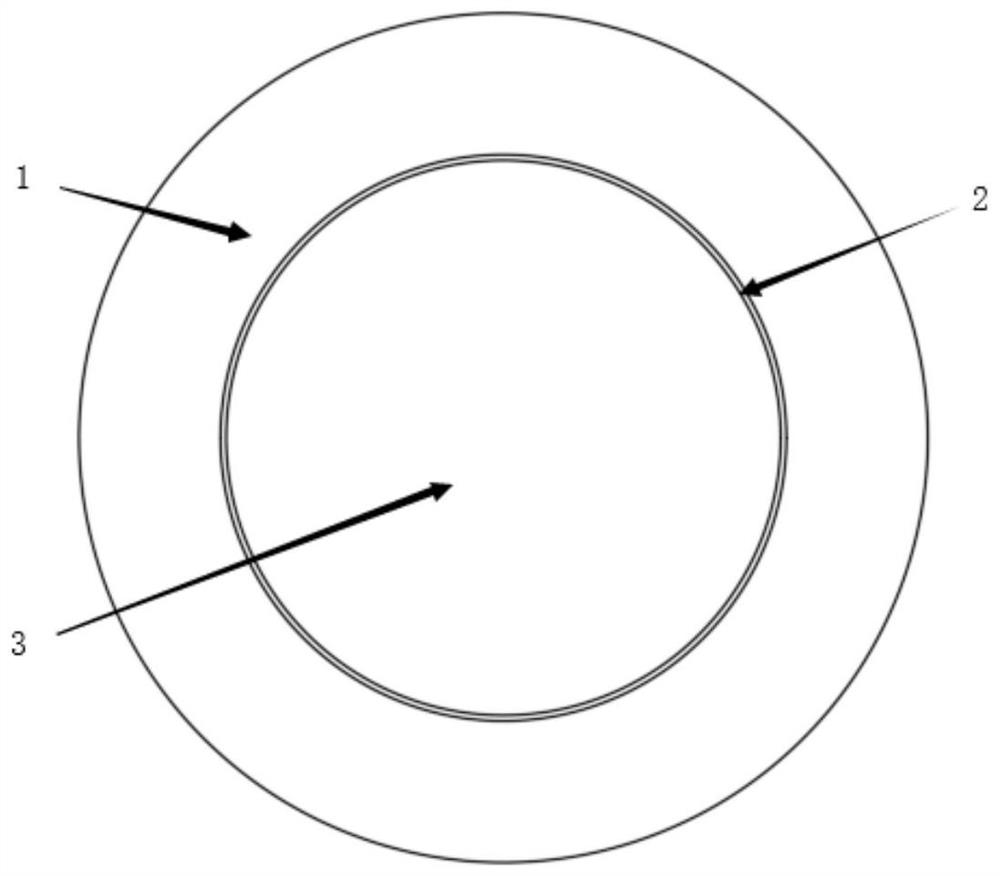

[0024] like figure 1 As shown, a carbon fiber composite frangible cover is mainly designed and manufactured with carbon fiber cloth and epoxy resin glue as the main material for the missile launch box cover. Specifically, the multi-functional flat composite launch case cover of the present invention mainly includes: a flange surface 1, which is a circular ring, and a throwing body 3 is arranged in the middle; the weak zone 2 is located between the flange surface 1 and the throwing The middle part of the connection of the body 3 is a ring concentric with the flange surface; the throwing body 3 is a circle concentric with the flange surface and the weak area, and adopts carbon fiber layup.

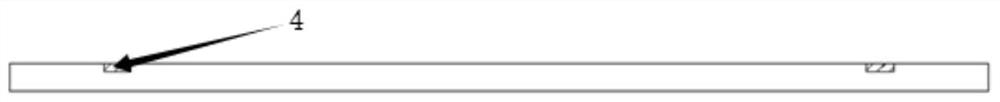

[0025] like figure 2 As shown, what is shown is a sectional structure of a fragile cover made of carbon fiber composite material. The middle weak area 2 is obtained by opening a groove 4 on the overall circular flat plate. Cured and formed, the carbon fiber cloth layer is a ladder laminat...

Embodiment 2

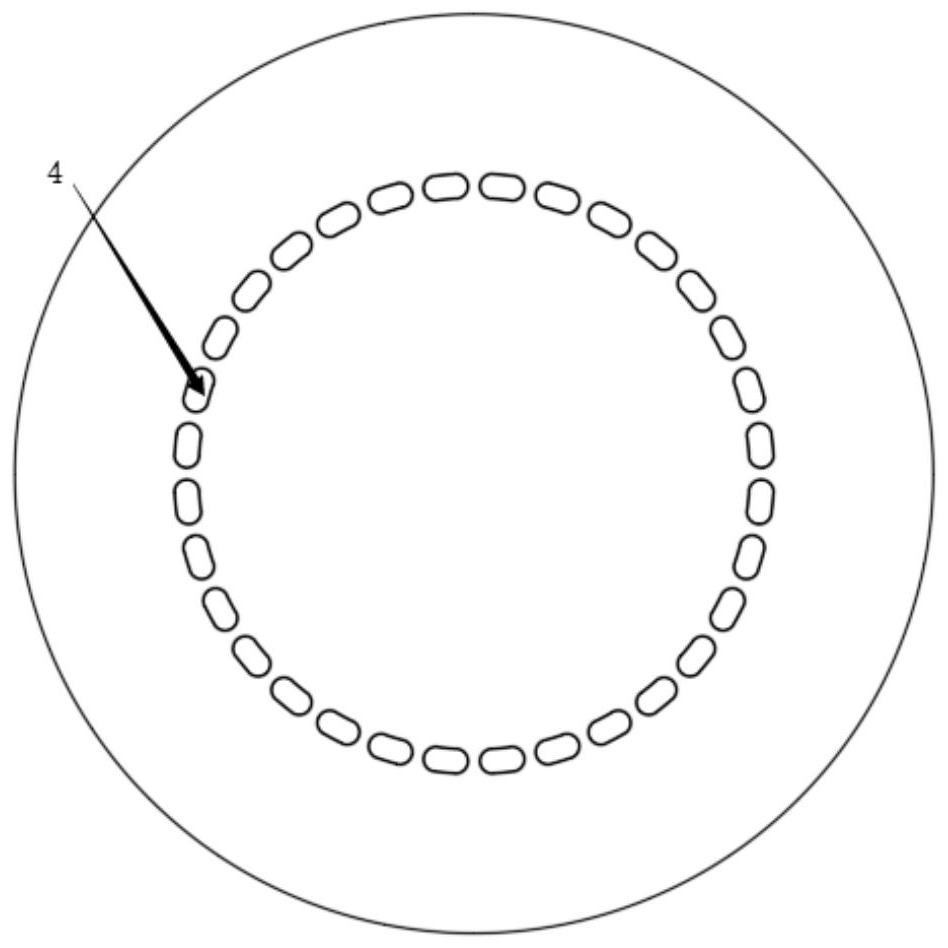

[0027] like image 3 As shown, what is shown is a fragile cover of carbon fiber composite material, which is mainly designed and made of missile launch box cover with carbon fiber cloth and epoxy resin as the main materials. Specifically, the carbon fiber composite frangible cover of the present invention mainly includes: a flange surface 1, which is a ring with a throwing body 3 in the middle; In the middle of , there is a ring concentric with the flange surface 1, and a fixed number of cashew-shaped holes are opened in the ring part, such as Figure 4 As shown, the hole is filled with resin material; the projectile body 3 is a circle concentric with the flange surface and the weak area, and adopts carbon fiber layup.

[0028] like Figure 5 The sectional structure of a fragile cover made of carbon fiber composite material shown is the same as that of Example 1. Open cashew-shaped holes in the weak area according to a fixed size and a fixed number, and fill them with epoxy...

Embodiment 3

[0030] like image 3 As shown, a carbon fiber composite fragile cover is mainly designed and manufactured with carbon fiber cloth and epoxy resin as the main material of the missile launch box cover. Specifically, the carbon fiber composite frangible cover of the present invention mainly includes: a flange surface 1, which is a ring; A ring concentric with the flange surface, the ring is partially opened with a fixed number of cashew-shaped holes, such as Figure 4 As shown, the hole is filled with resin material; the throwing body 3, the throwing body is a circle concentric with the flange surface and the weak area, and adopts carbon fiber layup.

[0031] like Figure 5 The sectional structure of a fragile cover made of carbon fiber composite material shown is the same as that of Example 1. Open cashew-shaped holes in the weak area according to a fixed size and a fixed number, and fill them with epoxy resin. When the overall diameter of the cover is set to 300mm, the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com