A semi-automatic demolding integrated machine and demolding method for large and small Marshall test pieces

A Marshall test piece and demoulding integrated technology, applied in the field of road engineering materials, can solve the problems of complex demoulding type mold switching, large influence of demoulding error samples, cumbersome demoulding process, etc., to achieve good social and economic benefits, Convenient and quick demoulding, solving the effect of messy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific working method of the present invention will be described in detail below with reference to the accompanying drawings.

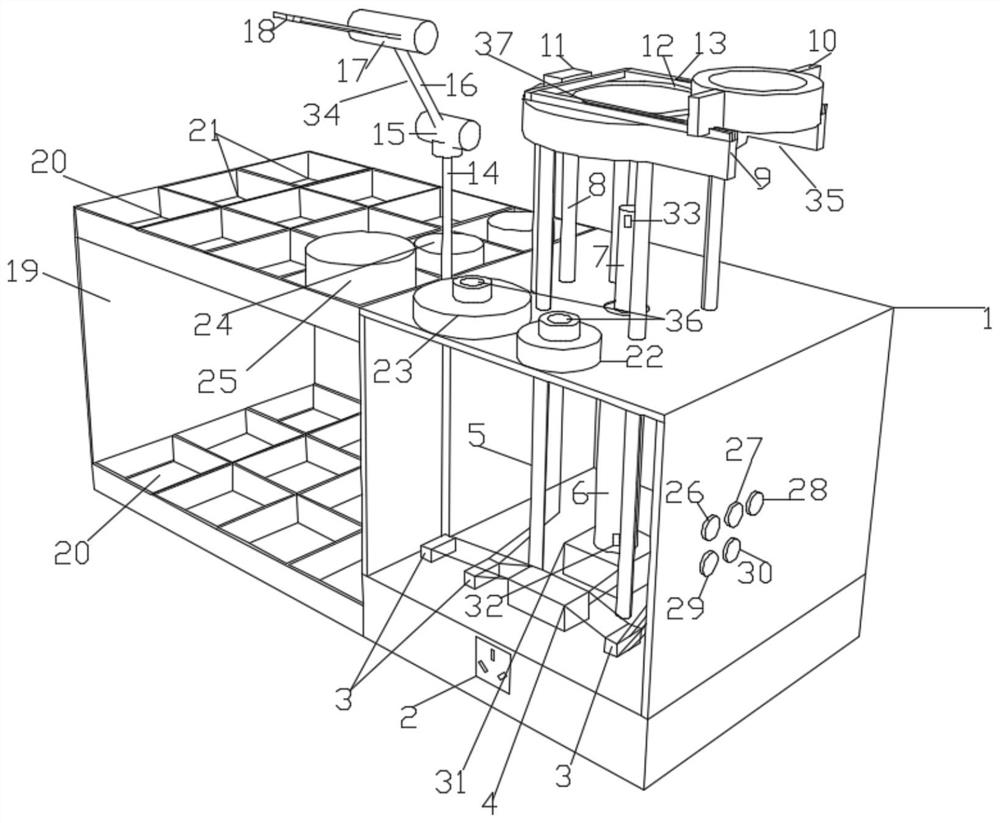

[0042] like figure 1 As shown in the figure, a semi-automatic demolding machine for large and small Marshall specimens includes a metal frame 1 on which a hub 3, a master controller 4, a hydraulic press 6, a hydraulic press motor 31, an electric mechanical arm 34, and a large and small Marshall specimen electric The card-block integrated machine 35, the hub transmits the signal of the signal control button to the master controller 4 through the signal line, and then transmits the instruction to each component.

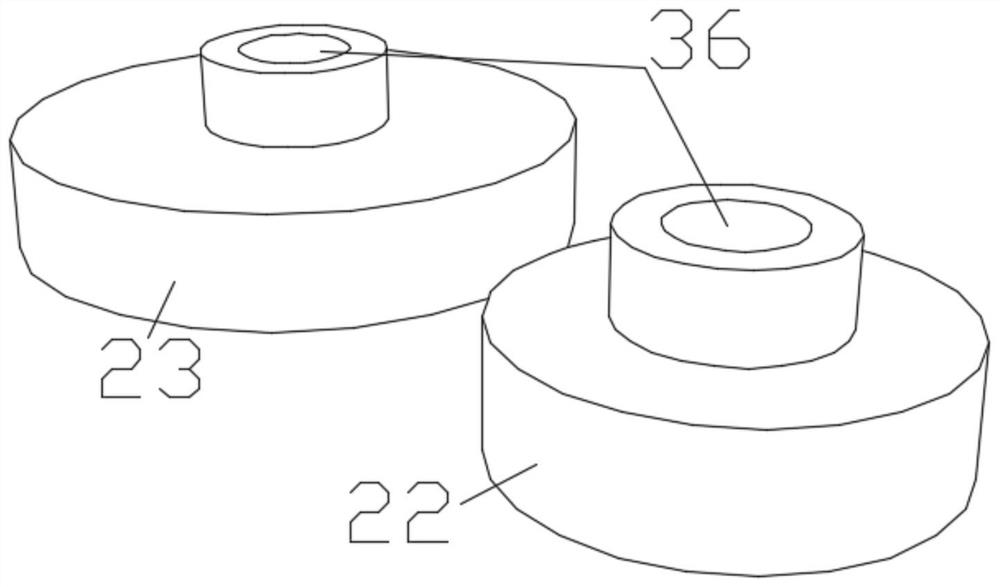

[0043] like figure 2As shown in the figure, a large Marshall test piece magnetic top block 23 and a small Marshall test piece magnetic top block 22 are provided with a non-penetrating groove in the middle, and the diameter of the middle groove 36 is matched with the diameter of the hydraulic press ejector rod 7, so as to In ord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com