An online testing method for dynamic characteristics of 3D printing of cement-based materials

A cement-based material, 3D printing technology, applied in the direction of flow characteristics, flow characteristics of non-Newtonian fluids, analysis of materials, etc. Reduce the effect of human intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

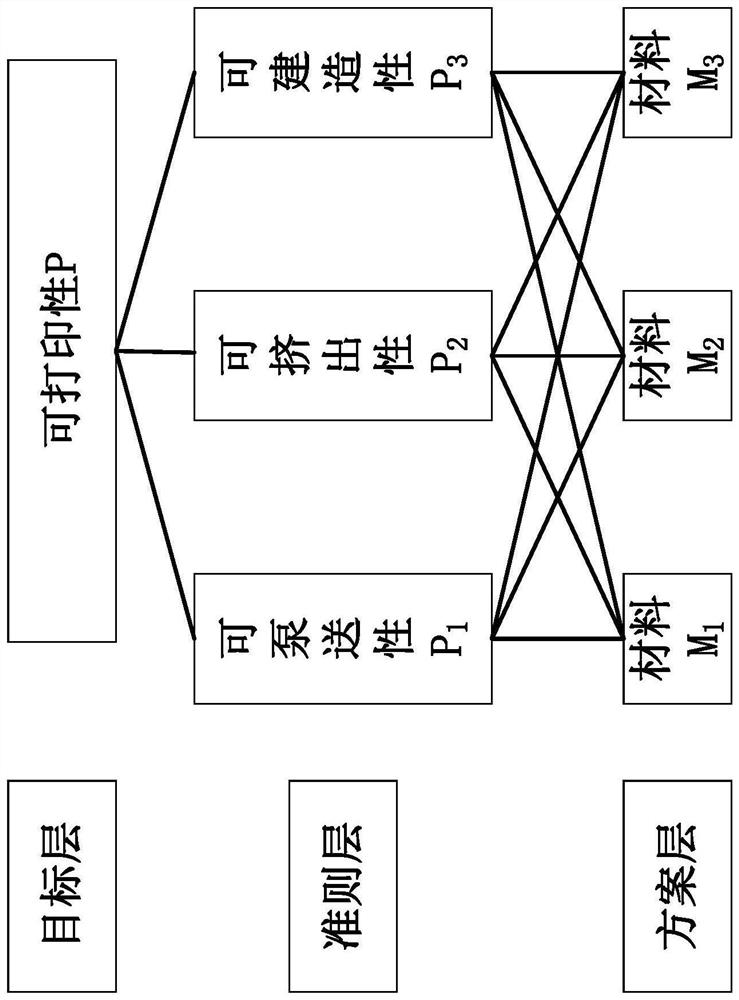

[0034] The invention provides an online testing method for 3D printing dynamic characteristics of cement-based materials, which is used to characterize and test the printability of cement-based materials.

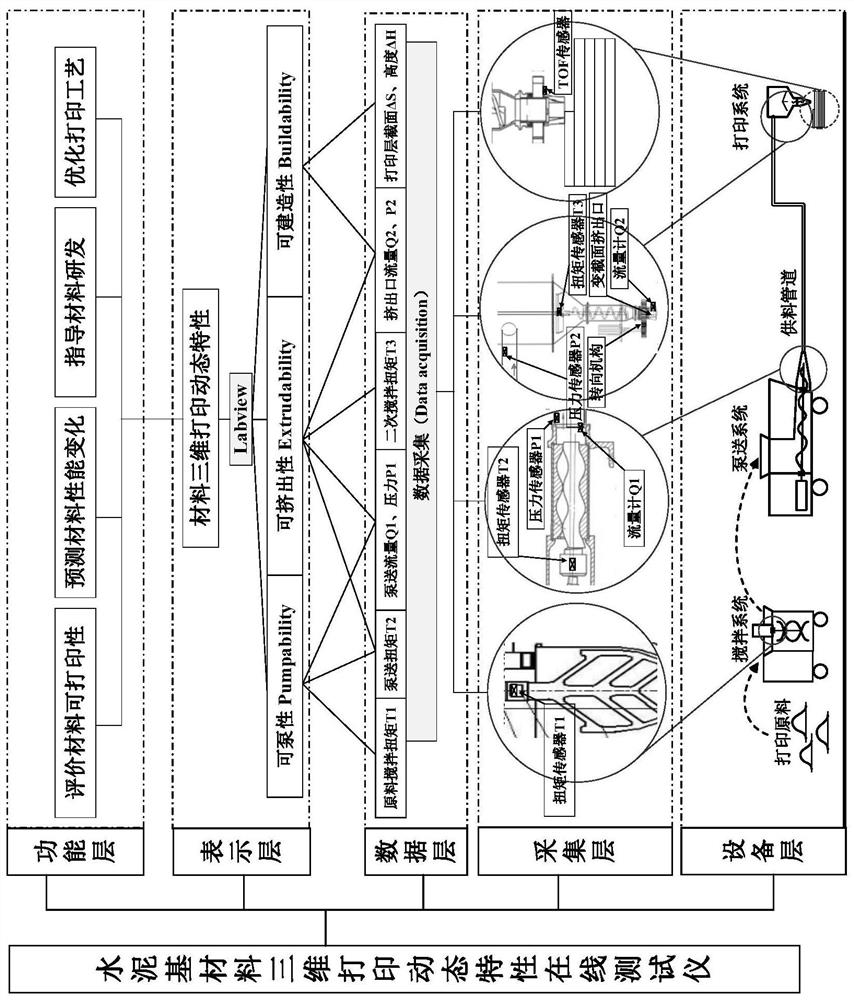

[0035] The overall structure of the online testing platform for 3D printing dynamic characteristics of cement-based materials is as follows: figure 1 shown. The instrument architecture is "bottom-up" with equipment layer, acquisition layer, data layer, presentation layer and function layer in sequence. Among them, the equipment layer (hardware platform) includes the mixing system, pumping system, CNC control system, feeding pipeline and extrusion printing system, etc.; The sensor T2 is located at the screw shaft of the pumping system, the torque sensor T3 is located at the extrusion screw shaft of the extrusion printing system, the pressure sensor P1 and the pressure sensor P2 are respectively located at the beginning and end of the feeding pipeline, and the flow meter Q1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com