Direct tire pressure sensor learning system, online learning system and method

A tire pressure sensor and vehicle technology, which is applied in the direction of instruments, tire measurement, tire parts, etc., can solve problems that do not involve tire pressure sensor identification methods, etc., so as to improve the success rate of tire pressure reading, optimize ergonomics, reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

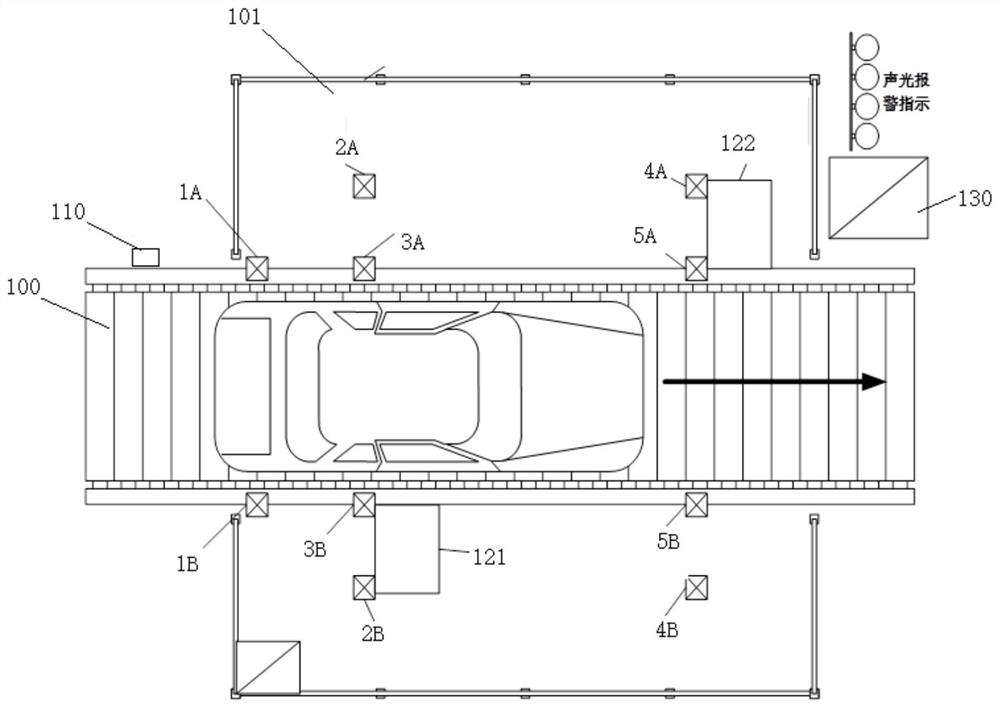

[0040] Such as figure 1 As shown, the vehicle conveying device 100 may be, but not limited to, a chain conveying device or a skid conveying device. It has an identification area 101 (also called a work station). The edge of the vehicle conveying device 100 in the recognition area 101 is provided with a vehicle identification device 110, the vehicle identification device 110 adopts RFID identification, and the downstream of the vehicle identification device 110 (vehicle transmission direction) is provided with vehicle position detection devices 1A, 1B, vehicle position detection device 1A , 1B is a photoelectric detection device, specifically an infrared detection device, which is used to detect whether the vehicle enters the scanning area.

[0041] The edge of the downstream vehicle conveying device 100 is provided with first wheel position detection devices 3A, 3B. The wheel position detection devices 3A, 3B are photoelectric detection devices, specifically infrared detectio...

Embodiment 2

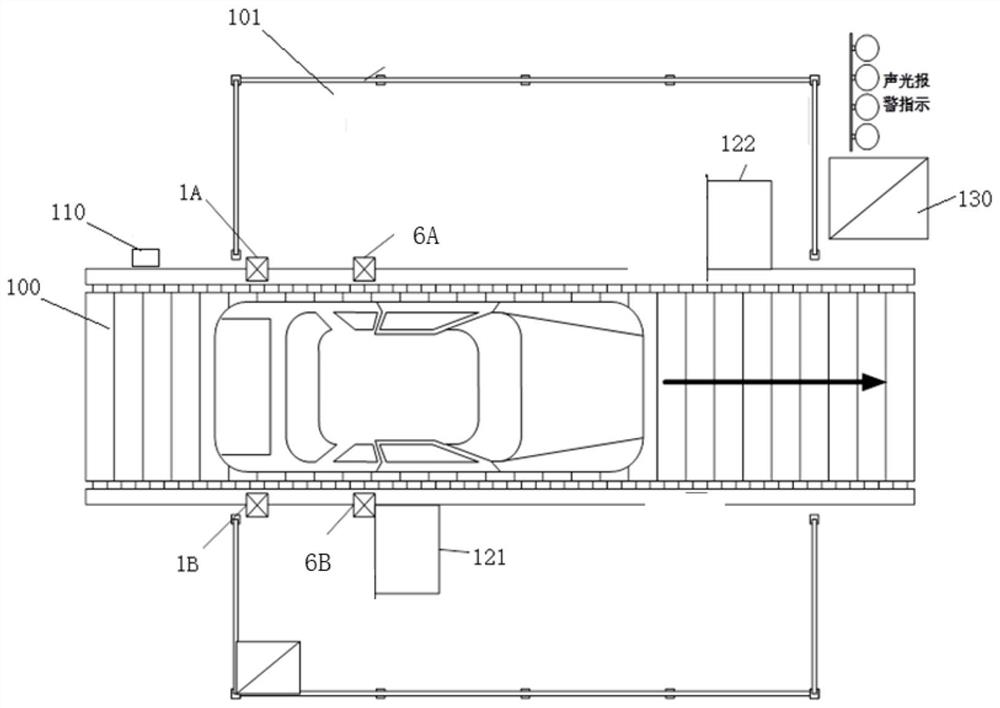

[0059] Such as image 3 As shown, the difference from Embodiment 1 is that in this embodiment, only one set of wheel position detection devices 6A and 6B is provided on the edge of the vehicle conveying device 100, and other devices are the same as in the embodiment.

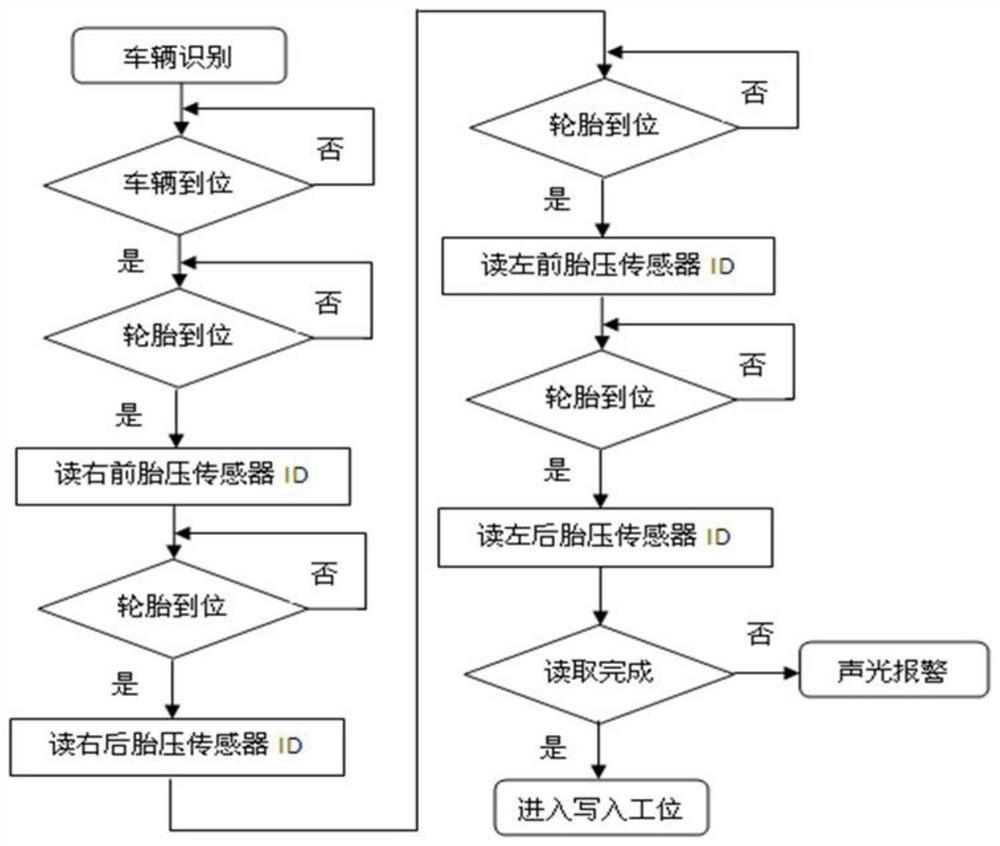

[0060] Such as Figure 4 As shown, the learning method process based on the above arrangement is:

[0061] The vehicle identification device 110 scans the vehicle through RFID, obtains the information of the vehicle, and determines the model of the vehicle; that is, reads the VIN code, configuration level, platform and other information through the vehicle information identification module, and the control program in the industrial computer starts to create the vehicle data table, Store the read vehicle information into the data table;

[0062] The vehicle position detection devices 1A, 1B detect and determine that the vehicle enters the identification area, and activate the first wheel position detection devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com