Method for quickly measuring wall thickness of annular section based on industrial CT

A measurement method and cross-section technology, applied in image data processing, instruments, calculations, etc., can solve the problem of not being able to obtain the maximum and minimum wall thickness of the rotary cavity components, and achieve slow calculation speed, fast operation calculation speed, and large memory Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

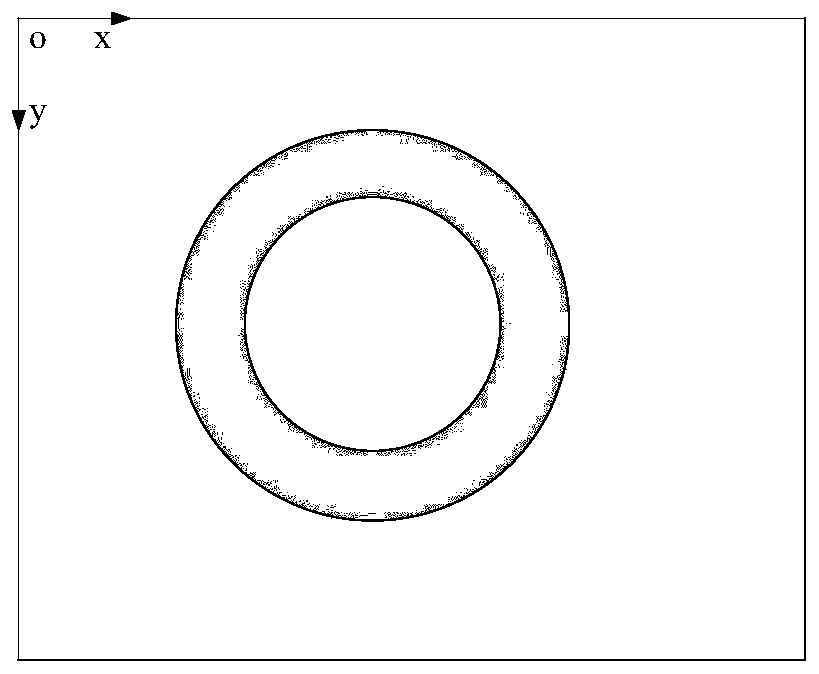

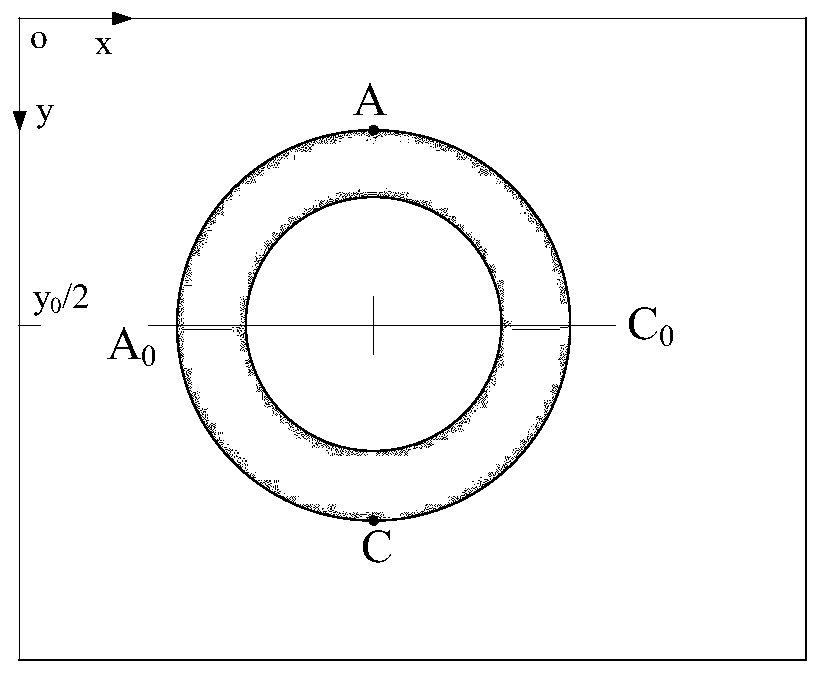

[0038] A specific embodiment of the present invention, such as Figure 1-Figure 5 As shown, a method for quickly measuring the thickness of an annular section based on industrial CT is disclosed. The steps include: Step 1: Obtain the annular section of the rotary cavity member, and divide the image area; Step 2: Determine the thickness of the annular section Coordinates of the center of the circle; Step 3: Calculate the maximum radius R of the circular section max , draw a virtual circle; Step 4: Calculate the pixel distance of any point in the virtual circle, and calculate the actual wall thickness of any point.

[0039] Compared with the prior art, in this embodiment, the industrial CT cross-sectional image of the position to be measured of the revolving cavity member is acquired by industrial CT imaging equipment, and the maximum and minimum values of the wall thickness of the ring member are calculated according to the industrial CT cross-sectional image. Under the prem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com