Flexible torsion-resistant tensile flexible cable for electric hydraulic vehicle and production process thereof

A production process and technology for flexible cables, applied in the manufacture of insulated cables, bendable cables, cables/conductors, etc., can solve problems such as insufficient stability and insufficiency, and achieve improved mechanical strength, uniform stress on conductors, and good tensile strength. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

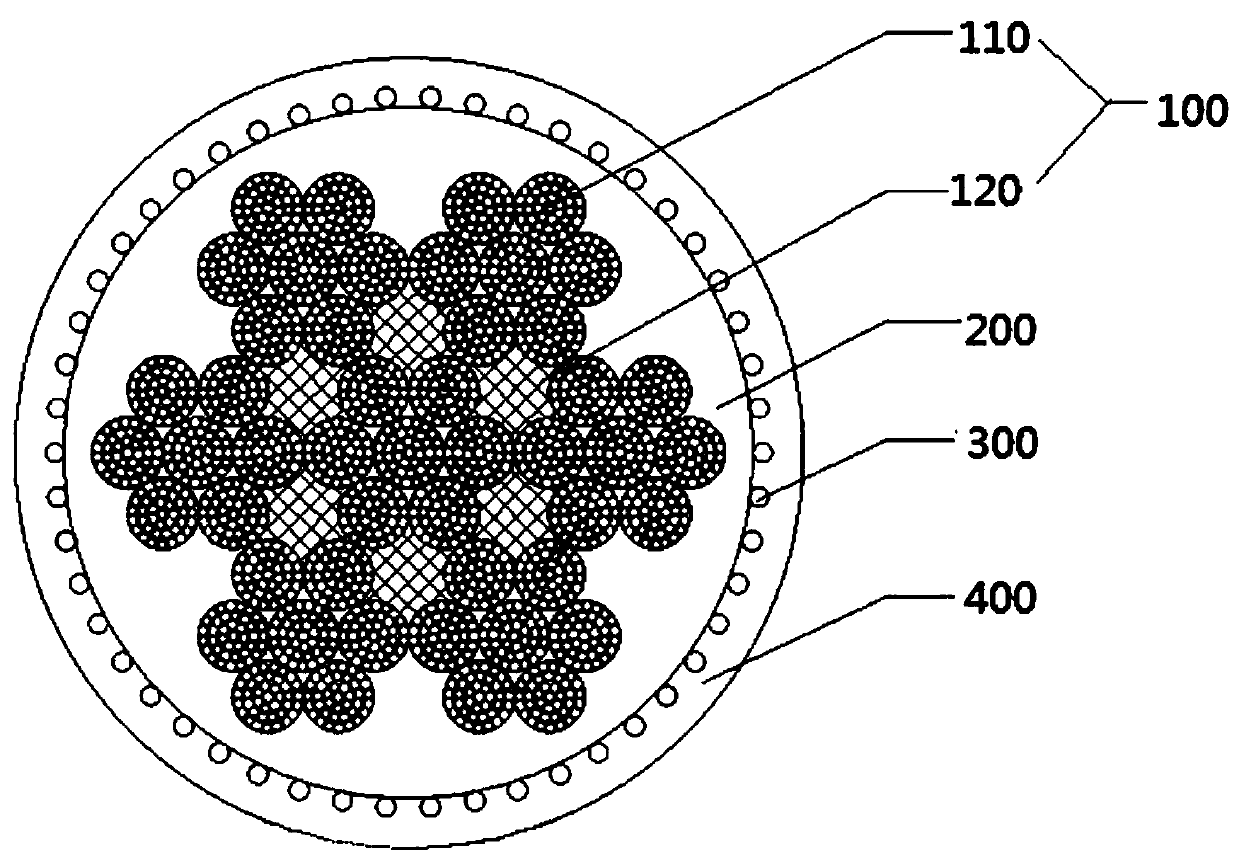

[0030] See figure 1 , a flexible torsion-resistant and tensile flexible cable for an electro-hydraulic vehicle, from the inside to the outside is a composite conductor 100, an inner insulation layer 200, a reinforcement layer 300 and an outer insulation layer 400; the composite conductor 100 includes 7 groups of conductor groups 110 and 6 bundles of copper foil tows 120; the 7 sets of conductor groups 110 are normally twisted in the manner of 1+6; the conductor groups 110 include 7 strands of conductor units, which are normally twisted in the manner of 1+6; The conductor unit adopts 40 copper wires arranged in a structure of 1+7+13+19; the conductor structure arranged in the above way is more compact and stable.

[0031] See figure 1 , the above-mentioned 6 bundles of copper foil tows 120 are respectively arranged in 6 gaps formed between the 6 groups of conductor groups 110 located in the outer layer and the 1 group of conductor groups 110 located in the center, so as to inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com