Sleeving press machine based on transformer coil

A technology for transformer coils and suits, which is applied in inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problems of difficulty, inability to suit, and low efficiency in coil assembly, avoiding manual stepping or coil disassembly work, accurate Good performance and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings.

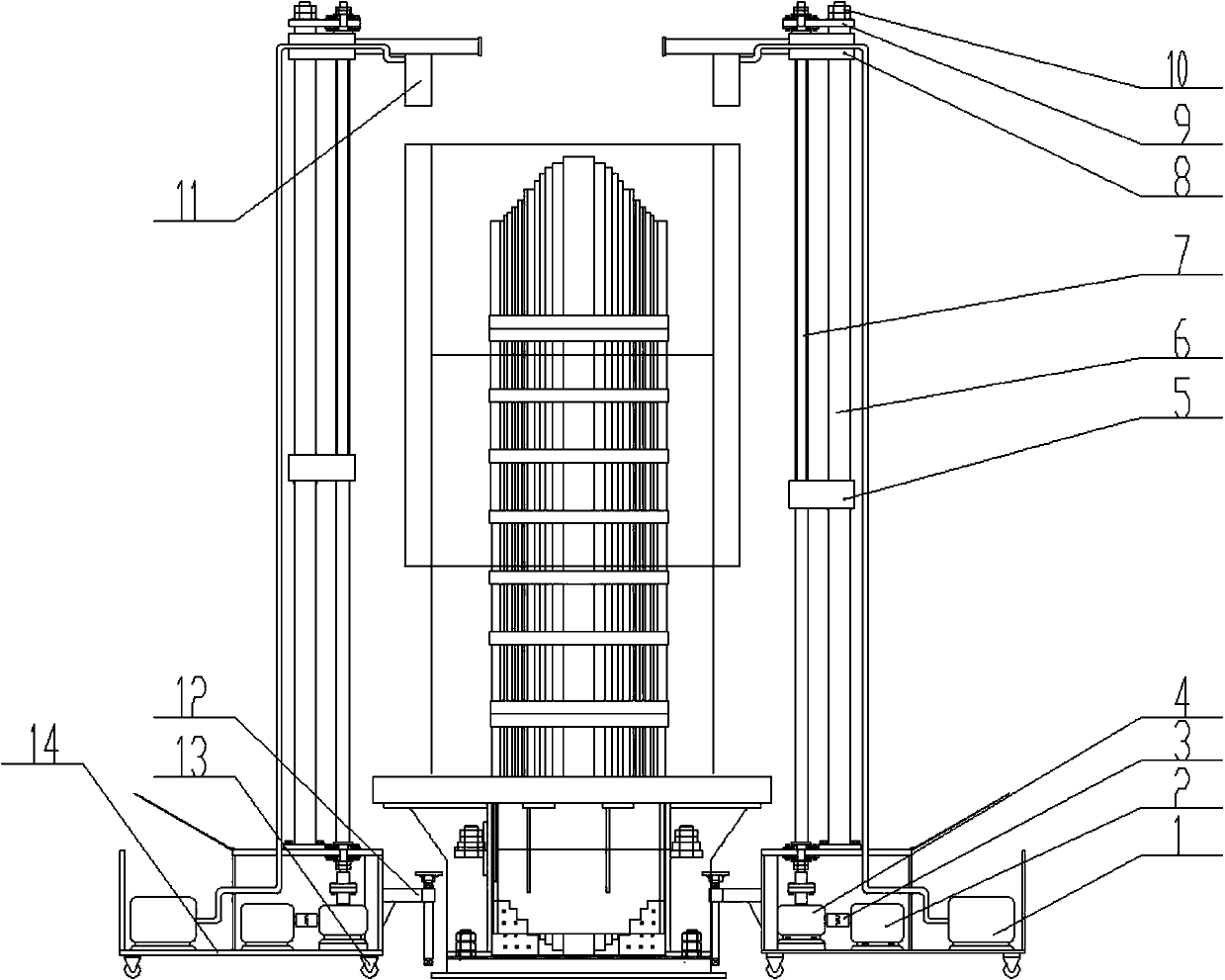

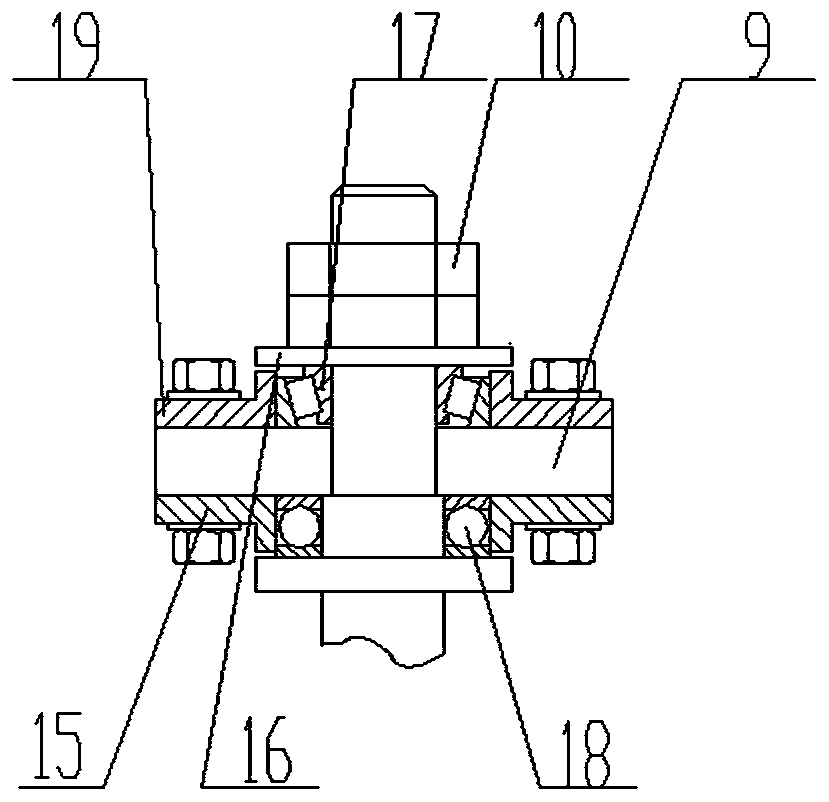

[0022] see Figure 1-2 , a press based on a transformer coil set, including a press body 14 for supporting, a hydraulic system 1 for providing pressure, a motor 2 for power supply, a speed reducer 4 for adjusting the speed, connecting the motor 2 and the speed reducer 4 The shaft coupling 3, the limit pad 5 for fixing, the pillar 6 for skeleton support, the screw 7 for transmission, the movable pad 8 for adjusting the working area, and the fixing of the fixed pillar 6 and the screw 7 Plate 9, nut 10 for fastening pillar 6, lead screw 7 and fixed plate 9, end jack 11 for applying pressure on movable block 8, support plate 12 for lower positioning, roller 13 for moving, pillar 6 It is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com