Method for producing a gas-sensitive nanocrystalline layer structure, corresponding gas-sensitive nanocrystalline layer structure, and gas sensor with a corresponding gas-sensitive nanocrystalline layer structure

A gas sensor, gas-sensitive technology, applied in the direction of manufacturing microstructure devices, microstructure technology, microstructure devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the figures, identical reference numbers indicate identical or functionally identical elements.

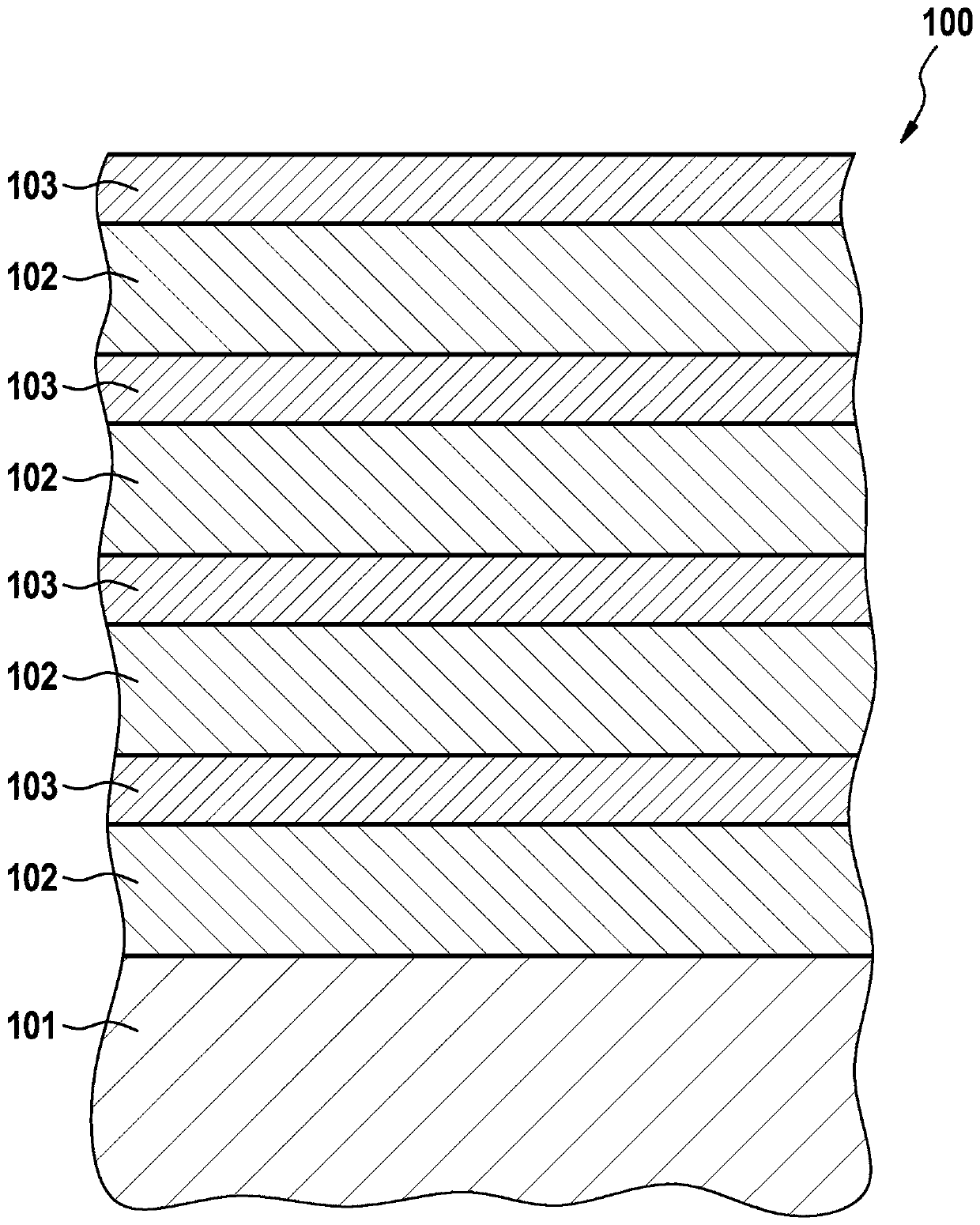

[0026] figure 1 A schematic illustration for explaining the layer structure according to the first embodiment of the invention before the temperature treatment step is shown in cross section.

[0027] figure 1 The case of an amorphous deposition of base material and dopant is shown, further morphologies are also conceivable, for example a base material which is already present in partially crystalline form after deposition, wherein the dopant material can already be deposited, in particular is the intrusion along the grain boundaries during the annealing step.

[0028] exist figure 1101 denotes an insulating layer (substrate), 102 denotes a base layer consisting of a base material, 103 denotes a doped layer consisting of a dopant material and 100 denotes after deposition, for example by sputtering or by an ALD process The entire layer structure before the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com