Assembling equipment for coaxial connector

A technology for coaxial connectors and assembly equipment, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve problems such as low efficiency, low precision, and small size of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

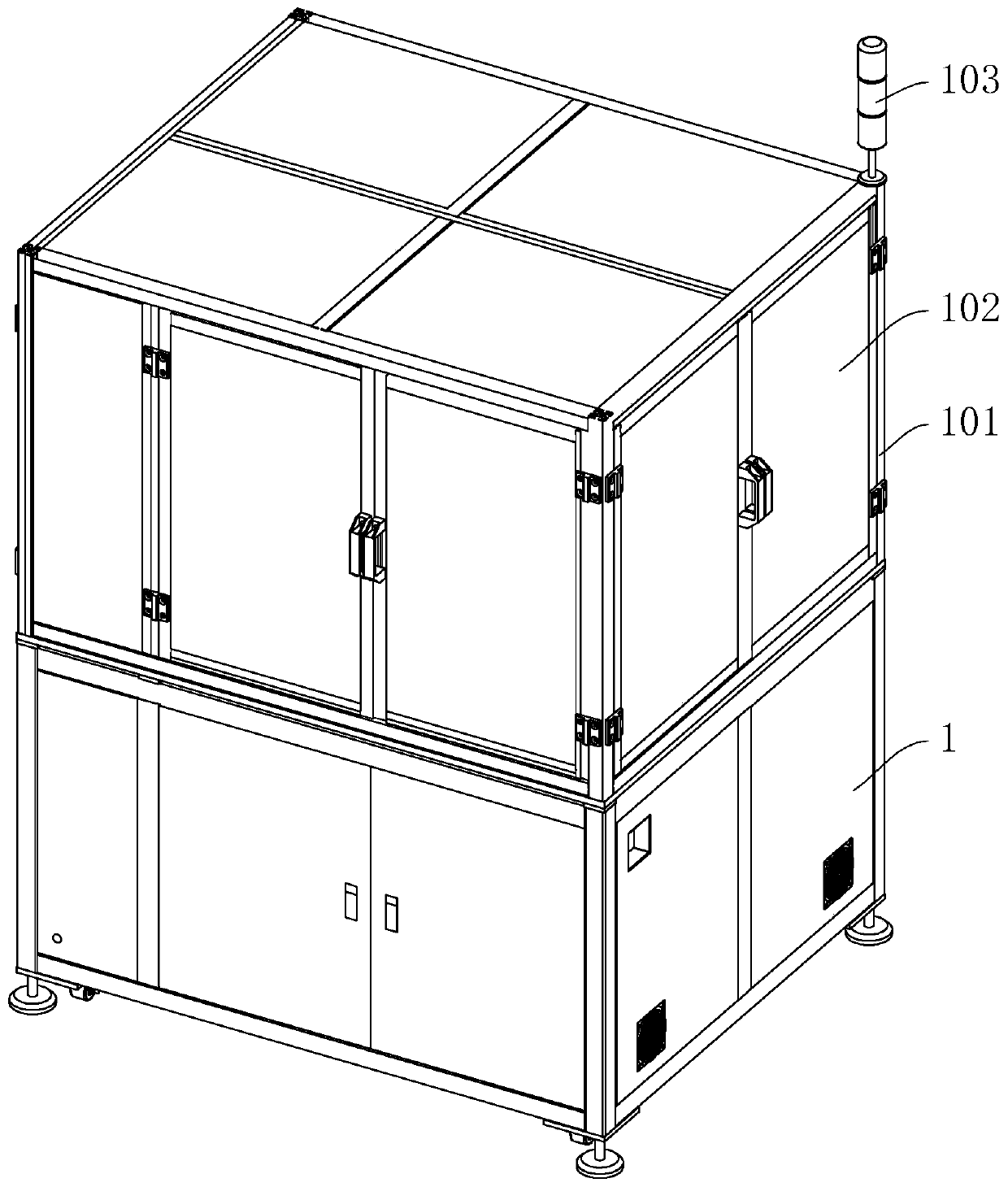

[0057] Embodiment: a kind of assembly equipment of coaxial connector, such as figure 1 As shown, it includes a workbench 1, the upper end of the workbench 1 is fixedly connected with a fixed frame 101, and a plurality of baffles 102 are hinged in the middle of the fixed frame 101. The baffles 102 can be opened to view the situation inside the workbench 1. The upper end of the workbench 1 An alarm 103 is provided, which can give an alarm when the work breaks down.

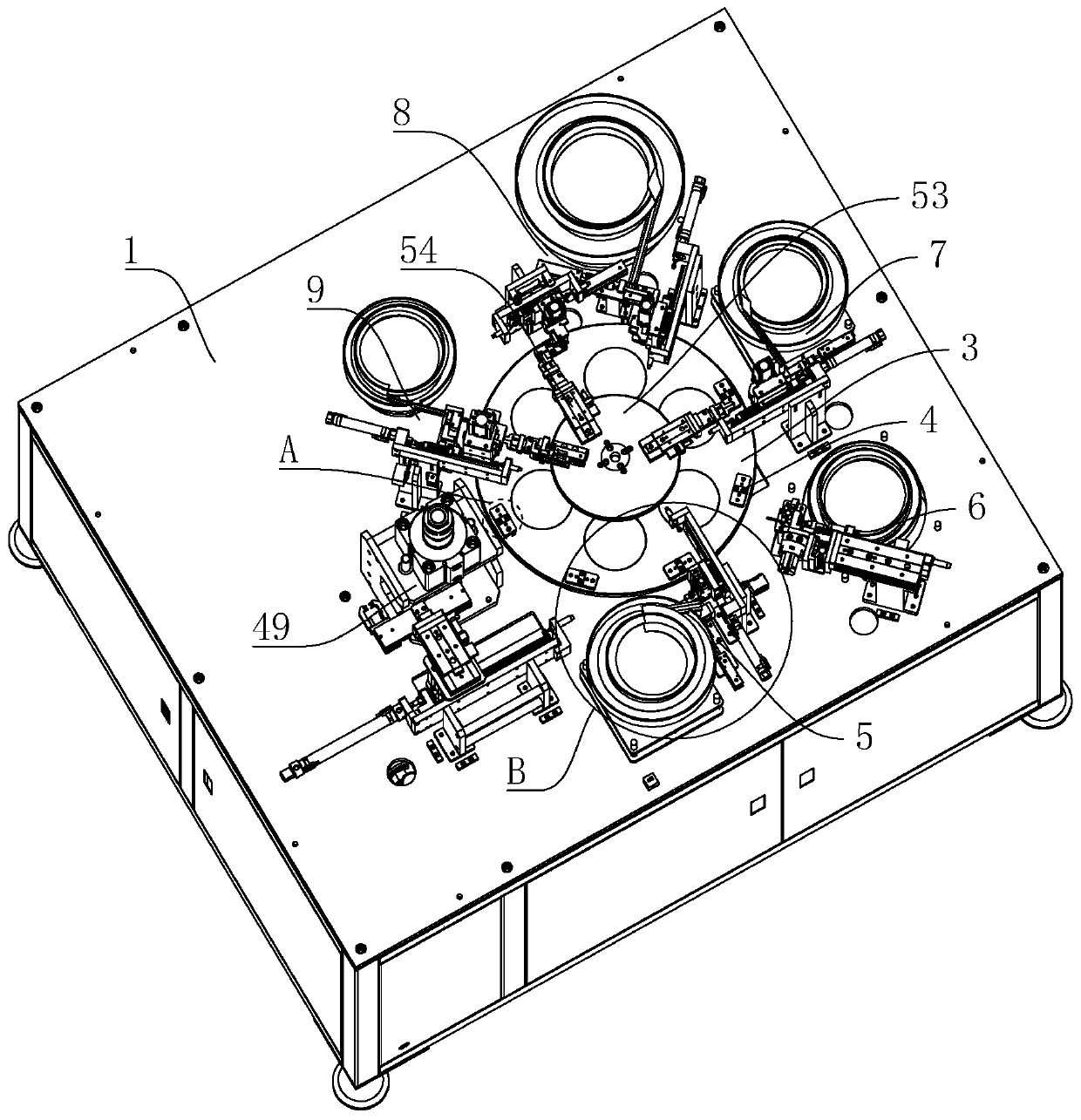

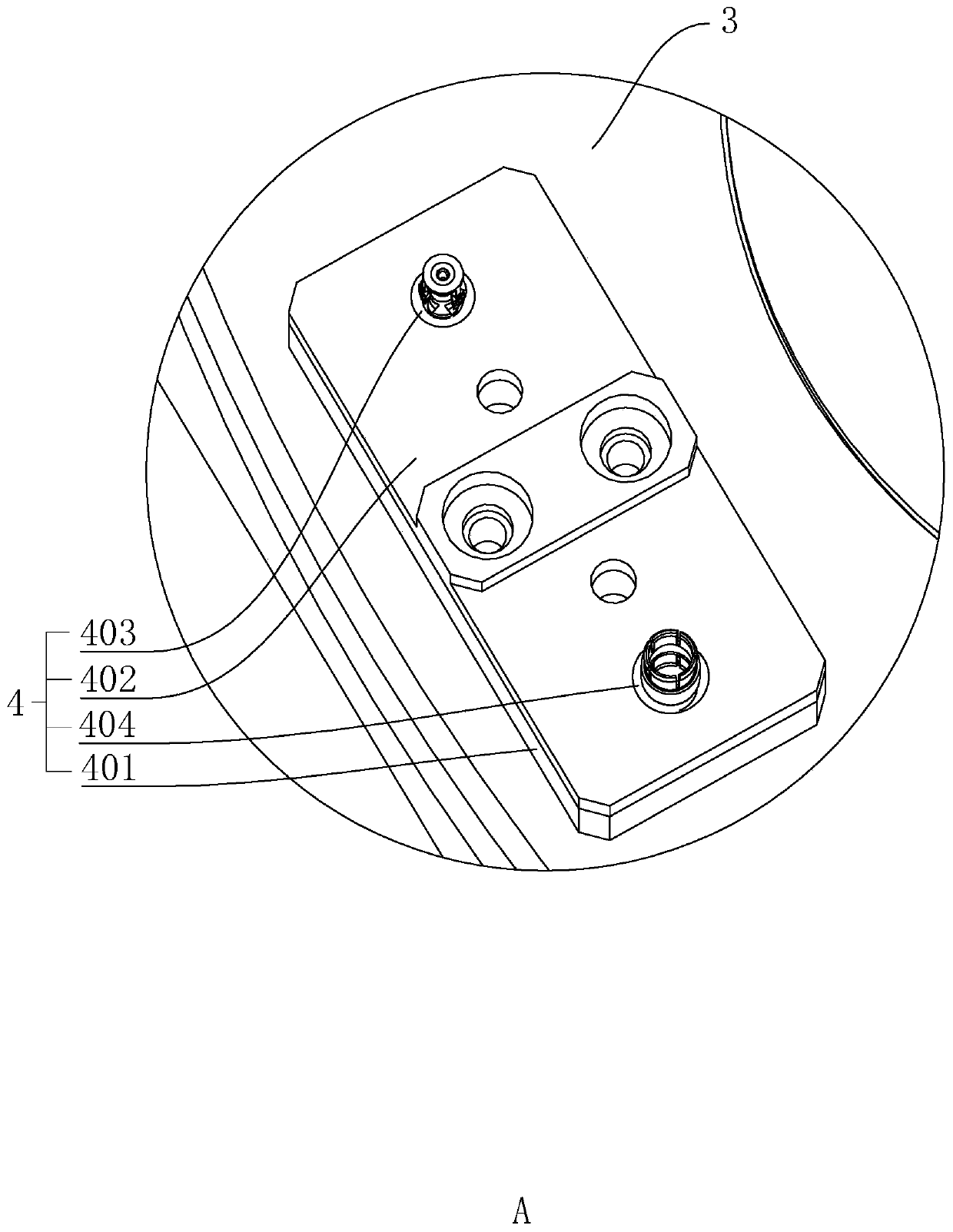

[0058] Such as figure 2 As shown, the upper end of workbench 1 is fixedly connected with drive motor 2 (refer to Figure 5 ), the drive motor 2 is linked with a drive turntable 3, and the upper end of the drive turntable 3 is provided with a plurality of fixtures 4. When assembling the coaxial connector, the drive motor 2 is started, and the drive motor 2 drives the drive turntable 3 to rotate intermittently. When it is time, it can drive the jig 4 to move intermittently.

[0059] Such as figure 2 As shown, th...

specific Embodiment approach

[0093] Specific implementation: when assembling the coaxial connector, place the lower insulator, the inner conductor, the upper insulator, the shell and the locking ring respectively on the lower insulator vibrating plate 501, the inner conductor vibrating plate 601, the upper insulator vibrating plate 701, Shell vibration plate 801 and locking ring vibration plate 901, and start the lower insulator vibration plate 501, the inner conductor vibration plate 601, the upper insulator vibration plate 701, the shell vibration plate 801 and the locking ring vibration plate 901, so that the lower insulator , Inner conductor, upper insulator, shell and locking ring vibration blanking.

[0094]Start the drive motor 2, and the drive motor 2 can drive the drive turntable 3 to rotate. When the drive turntable 3 rotates, it can drive the tooling fixture 4 to rotate. Component 6, upper insulator mounting component 7, shell mounting component 8, and locking ring mounting component 9 are link...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com