Automatic control device for hydrogen fluoride supply

An automatic control device and hydrogen fluoride technology, applied in the field of electrolytic fluorine production, can solve the problems of low automation level of electrolytic cells, and achieve the effects of eliminating the possibility of contact, continuous feeding and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

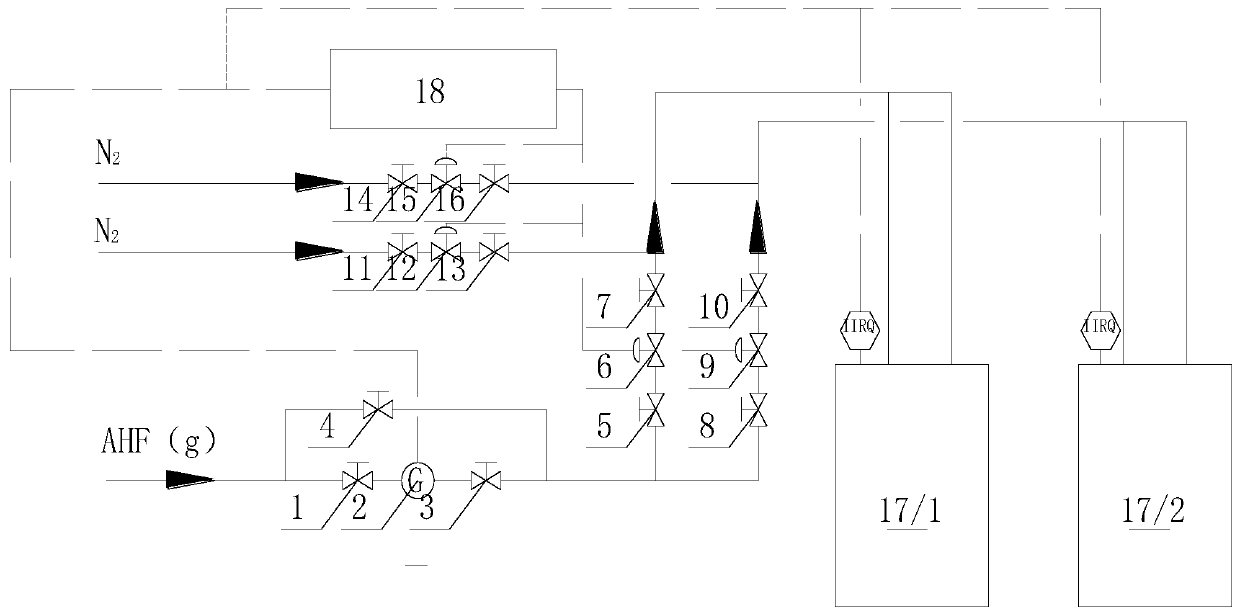

[0038] Such as figure 1 Shown, the automatic control device of a kind of hydrogen fluoride feeding of the present invention, this device comprises:

[0039] Stop valve one 1, mass flow meter 2, stop valve two 3, stop valve three 4, stop valve four 5, pneumatic valve one 6, stop valve five 7, stop valve six 8, pneumatic valve two 9, stop valve seven 10, Ball valve three 11, solenoid valve two 12, ball valve one 14, solenoid valve one 15, ball valve two 16, electrolytic tank one 171, electrolytic tank two 172, DCS automatic control module 18;

[0040] Set shut-off valve 1, mass flow meter 2, shut-off valve 2 and 3 sequentially from the hydrogen fluoride inlet;

[0041] A shut-off valve 3 4 is arranged in parallel between the shut-off valve 1, the mass flow meter 2, and the shut-off valve 2 3;

[0042] After the cut-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com