Primary-secondary air coupling jet system and operation method thereof

A technology of a jet system and an operating method, which is applied in the direction of combustion method, air supply adjustment, combustion air/fuel supply, etc., can solve the problems of increased emission concentration and high furnace temperature, achieve improved fuel burnout performance, and reduce NOx emissions Concentration, the effect of reducing the amount of combustion air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

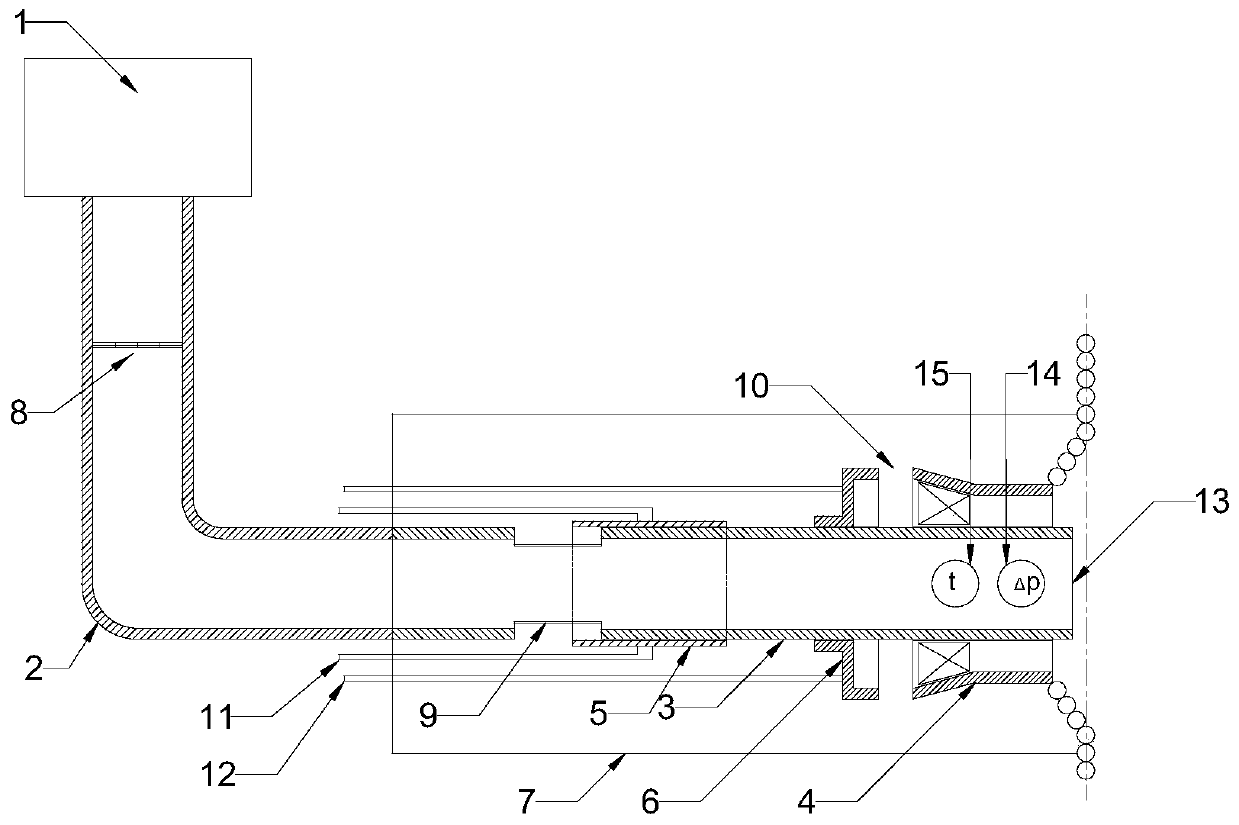

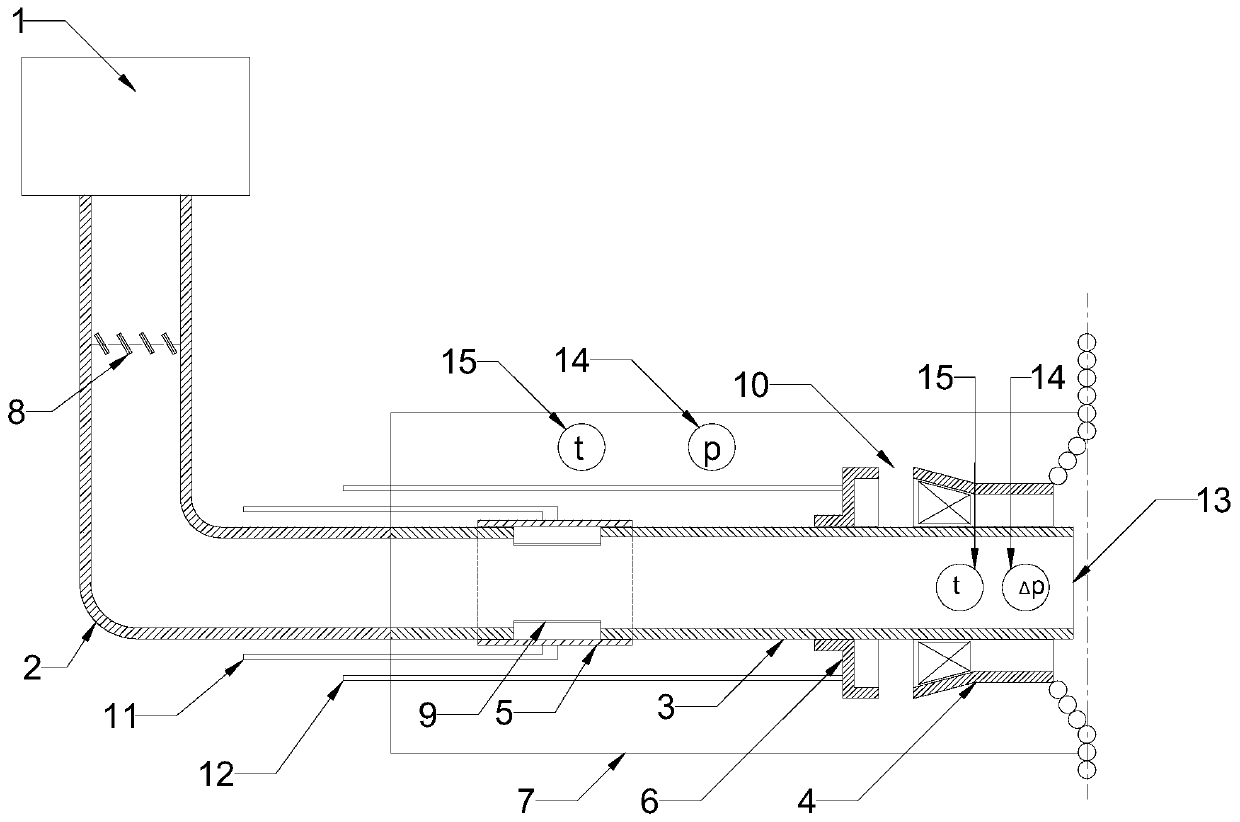

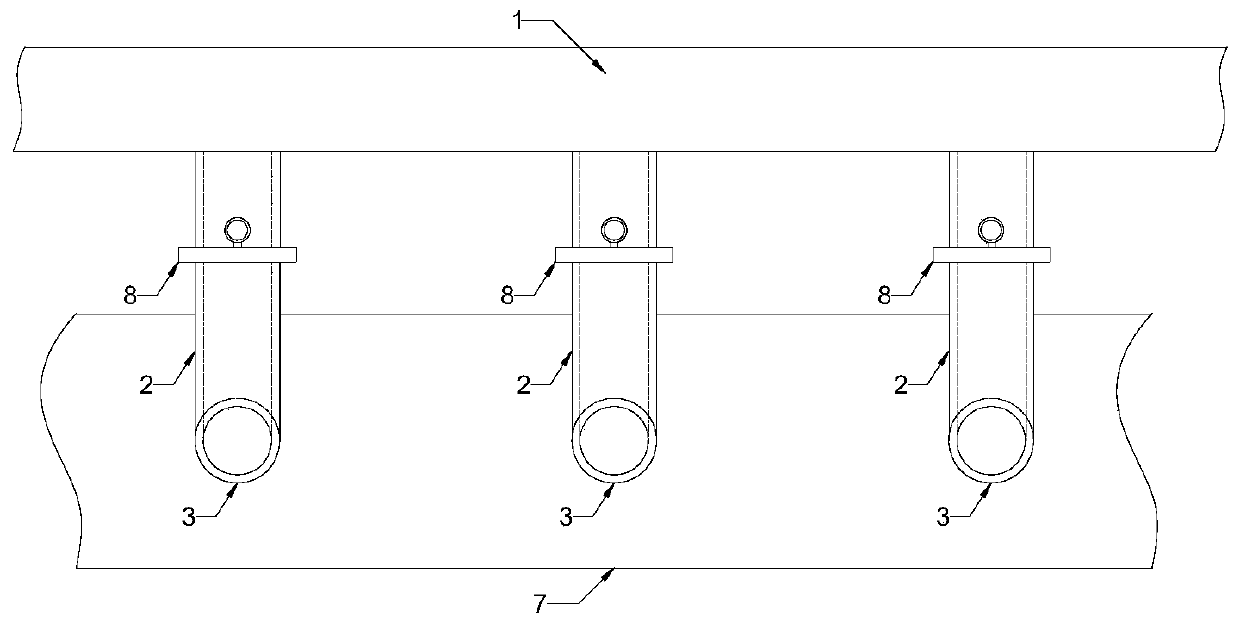

[0031] This embodiment provides a secondary air coupling jet system, such as Figure 1-2 As shown, it includes primary air main pipe 1, primary air branch pipe 2, direct current jet pipe 3, swirl jet pipe 4, direct current secondary air adjustment sleeve 5, swirl air regulating disc 6, secondary air box 7 and direct current primary Air regulating valve 8.

[0032] The primary air main pipe 1 is heated by primary air, and the primary air main pipe 1 is arranged along the furnace.

[0033] One end of the primary air branch pipe 2 is connected to the primary air main pipe 1, and the other end is connected to the direct current jet pipe 3; a direct current primary air regulating valve 8 is arranged on it.

[0034] Described direct current jet pipe 3, one end that is connected with direct current jet pipe 3 is direct current primary air inlet; A Pitot tube 14 and a temperature sensor 15 are installed inside the outlet 13 of the jet tube.

[0035] Said swirl jet pipe 4, one end c...

Embodiment 2

[0041] This embodiment provides the operation method of the primary-secondary air coupled jet system described in Embodiment 1, which monitors the DC jet velocity inside the outlet 13 of the DC jet tube online, and adopts different operating methods according to the magnitude of the DC jet velocity.

[0042] Such as figure 1 As shown, when the unit is running under high load conditions, the pressure of the secondary air box is high, and the DC jet velocity of the secondary air entering the DC jet pipe 3 through the DC secondary air inlet 9 is higher than the empirical airflow velocity. At this time, the DC primary air adjustment The valve 8 does not need to be opened, the direct current secondary air regulating sleeve 5 and the swirl air regulating disk 6 maintain proper openings, and the secondary air is sprayed into the furnace from the direct current jet tube 3 and the swirl jet tube 4 respectively.

[0043] Such as figure 2 As shown, when the load of the unit decreases, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com