Leaky cable fixture with multiple self-locking functions

A leaky cable and self-locking technology, applied in electrical components and other directions, can solve the problems of inconvenient installation, low installation efficiency, low tensile and shear bearing capacity, etc., to achieve convenient installation, improve installation efficiency, and resist shearing The effect of increasing the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

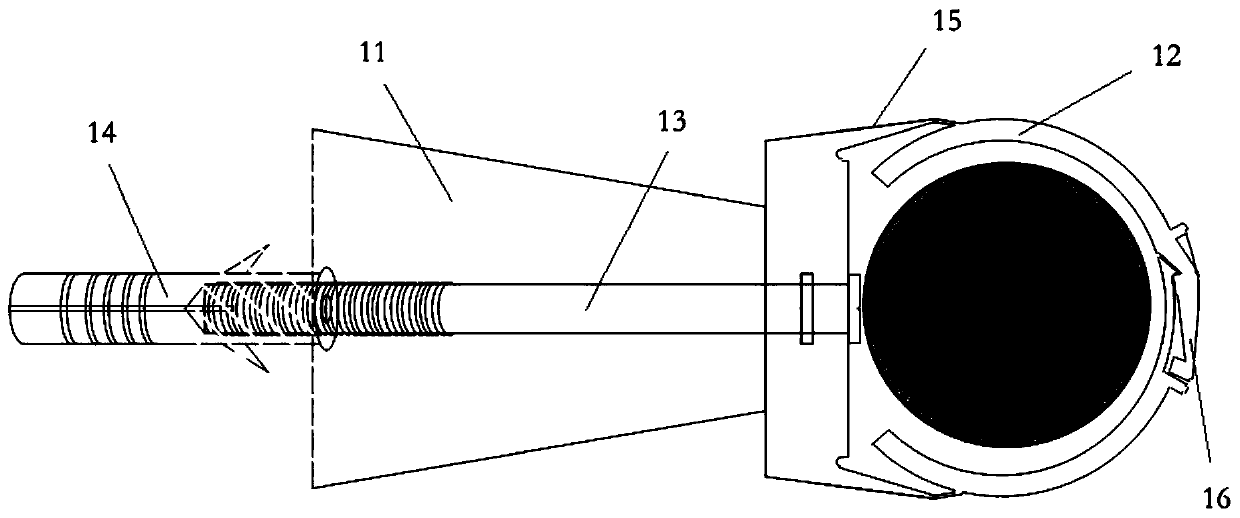

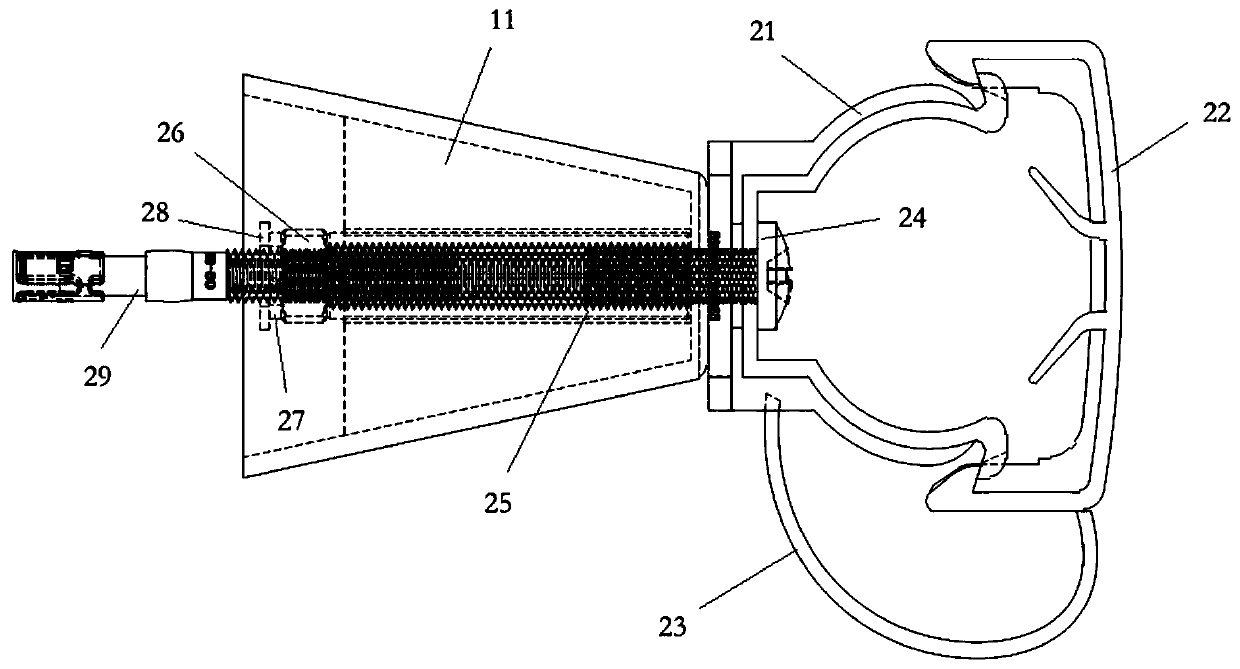

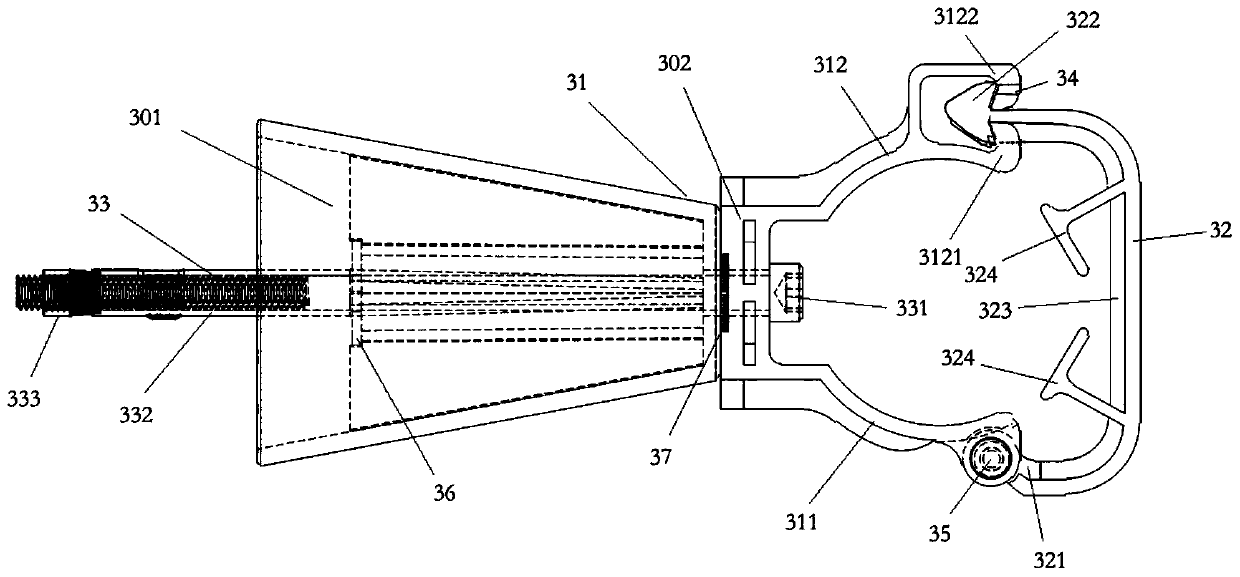

[0051] see Figure 3 to Figure 8 , image 3 It is a structural schematic diagram of a leaky cable fixture in Embodiment 1; Figure 4 It is a schematic structural diagram of a deck in Embodiment 1; Figure 5 It is a structural schematic diagram of a deck in Embodiment 1; Image 6 It is a structural schematic diagram of a card cover in Embodiment 1; Figure 7 It is a structural schematic diagram of a base in Embodiment 1; Figure 8 It is a structural schematic diagram of the base of Embodiment 1;

[0052] As shown in the figure, a leaky cable fixture with multiple self-locking functions of the present invention includes a fixing seat 31 and a card cover 32 for fixing the leaky cable. In this embodiment, the materials of the fixing seat 31 and the card cover 32 Nylon is preferred. The fixed seat 31 includes a base 301 and a card seat 302, and the card seat 302 is provided with two symmetrical large semicircular arcs, which are respectively a first claw 311 and a second claw...

Embodiment 2

[0065] The fixing seat 31 described in Embodiment 1 may not be a split structure, and may also be an integral injection molding structure, such as Figure 9 shown.

[0066] A leaky cable clamp with multiple self-locking functions of the present invention has the following beneficial effects:

[0067] (1) The leaky cable clamp with multiple self-locking functions of the present invention adopts an integral installation mode, which is convenient to install and also improves installation efficiency;

[0068](2) The leaky cable clamp with multiple self-locking functions of the present invention adopts an expansion anchor bolt fastening method, which is safer and more reliable than the traditional nylon expansion pipe anchoring method;

[0069] (3) In the leaky cable fixture with multiple self-locking functions of the present invention, the hook is provided with an anti-loosening structure, which realizes multiple self-locking, and its tensile bearing capacity and shear bearing ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com