Cheese sauce and preparation method thereof

A cheese sauce, cream cheese technology, applied in dairy products, cheese substitutes, applications, etc., can solve problems such as low nutritional value, and achieve the effects of high nutritional value, rich milk flavor and delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

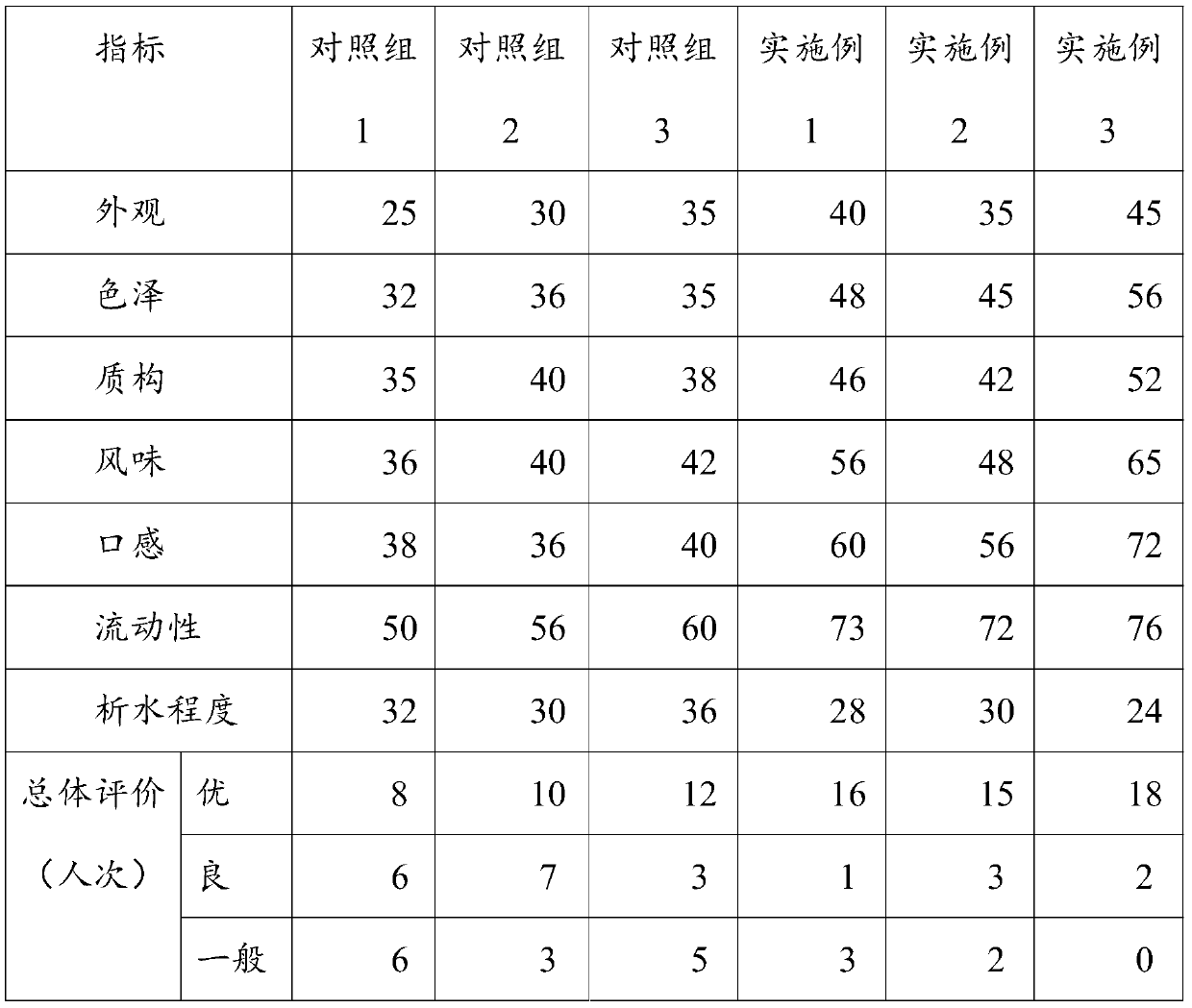

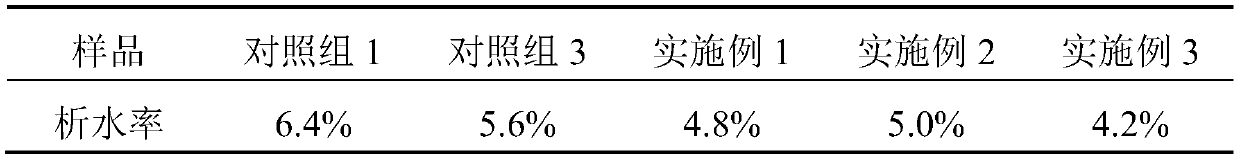

Examples

Embodiment 1

[0042] The embodiment of the present invention provides a kind of cheese sauce, and its formula is as follows:

[0043] raw material Amount wt% cheddar cheese 8 cream cheese 12 whey protein powder 16 whole milk powder 4 cream 18 emulsifying salt 0.2 stabilizer 0.1 salt 0.3 purified water margin total 100

[0044] Its production process is carried out according to the following steps:

[0045] (1) Heat cheddar cheese (2 months maturity), cream cheese, cream, whey protein powder, whole milk powder, emulsifying salt, table salt and stabilizer to 45°C and keep stirring for 10 minutes. Melt the cheese ingredients and fully hydrate the ingredients;

[0046] (2) Insulating the material obtained in step (1) at 45° C., and adding lactic acid to adjust the pH to 5.0;

[0047] (3) Heat the material obtained in step (2) at 95°C for 3 minutes to sterilize it. After the sterilization is completed, homogenize it wh...

Embodiment 2

[0049] The embodiment of the present invention provides a kind of cheese sauce, and its formula is as follows:

[0050] raw material Amount wt% cheddar cheese 15 cream cheese 7 whey protein powder 7 whole milk powder 12 cream 35 emulsifying salt 0.7 stabilizer 0.4 salt 0.5 purified water margin total 100

[0051] Its production process is carried out according to the following steps:

[0052] (1) Heat cheddar cheese (6-month maturation period), cream cheese, cream, whey protein powder, whole milk powder, emulsifying salt, table salt and stabilizer to 60°C and keep stirring for 3 minutes. Melt the cheese ingredients and fully hydrate the ingredients;

[0053] (2) Insulating the material obtained in step (1) at 60° C., and adding citric acid to adjust the pH to 5.6;

[0054] (3) Heat the material obtained in step (2) at 80°C for 10 minutes to sterilize. After the sterilization is completed, homogenize ...

Embodiment 3

[0056] The embodiment of the present invention provides a kind of cheese sauce, and its formula is as follows:

[0057] raw material Amount wt% cheddar cheese 12 cream cheese 10 whey protein powder 11 whole milk powder 8 cream 26 emulsifying salt 0.5 stabilizer 0.3 salt 0.75 purified water margin total 100

[0058] Its production process is carried out according to the following steps:

[0059] (1) Heat cheddar cheese (4-month maturation period), cream cheese, cream, whey protein powder, whole milk powder, emulsifying salt, table salt and stabilizer to 55°C and keep stirring for 5 minutes. Melt the cheese ingredients and fully hydrate the ingredients;

[0060] (2) heat the material obtained in step (1) at 55°C, and add GDL to adjust the pH to 5.3;

[0061] (3) Heat the material obtained in step (2) at 90°C for 5 minutes to sterilize it. After the sterilization is completed, homogenize it while it is ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com