Adsorption material for purifying sludge incineration flue gas and preparation method thereof

An adsorption material and sludge incineration technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of unsatisfactory removal efficiency, high equipment and material costs, and inability to completely degrade, etc. Low, easy-to-operate, easily-sourced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

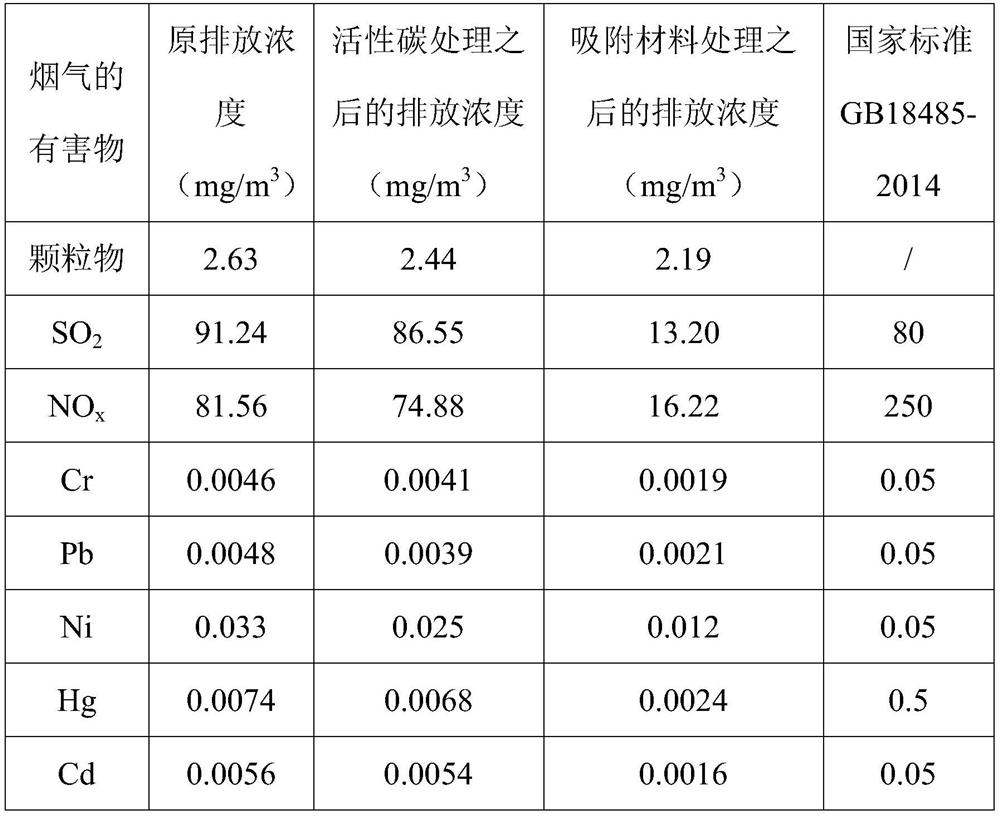

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below through specific implementation examples. It should be understood that these examples are only used to illustrate the present invention and not to limit the protection scope of the present invention. All equivalent modifications are within the meaning of the appended claims.

[0023] Unless otherwise specified, all the raw materials and reagents of the present invention are the raw materials and reagents in the conventional market.

[0024] A preparation method of an adsorption material for purifying sludge incineration flue gas, comprising the following steps:

[0025] 1) Preparation of mixed materials: take 10g of sodium alginate and dissolve it in 8g of water to form a sodium alginate solution, take 10g of chitosan and dissolve it in 8g of mineral acid solution, stir and dissolve fully, add sodium alginate solution and 5g of waste biomass material and 2g calcium-based bentonite, stir to form a viscous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com