Environment-friendly waste paper crushing device

A crushing device and waste paper technology, applied in grain processing, etc., can solve problems such as poor flexibility of use and incomplete crushing, and achieve the effects of easy operation, improved convenience, and avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

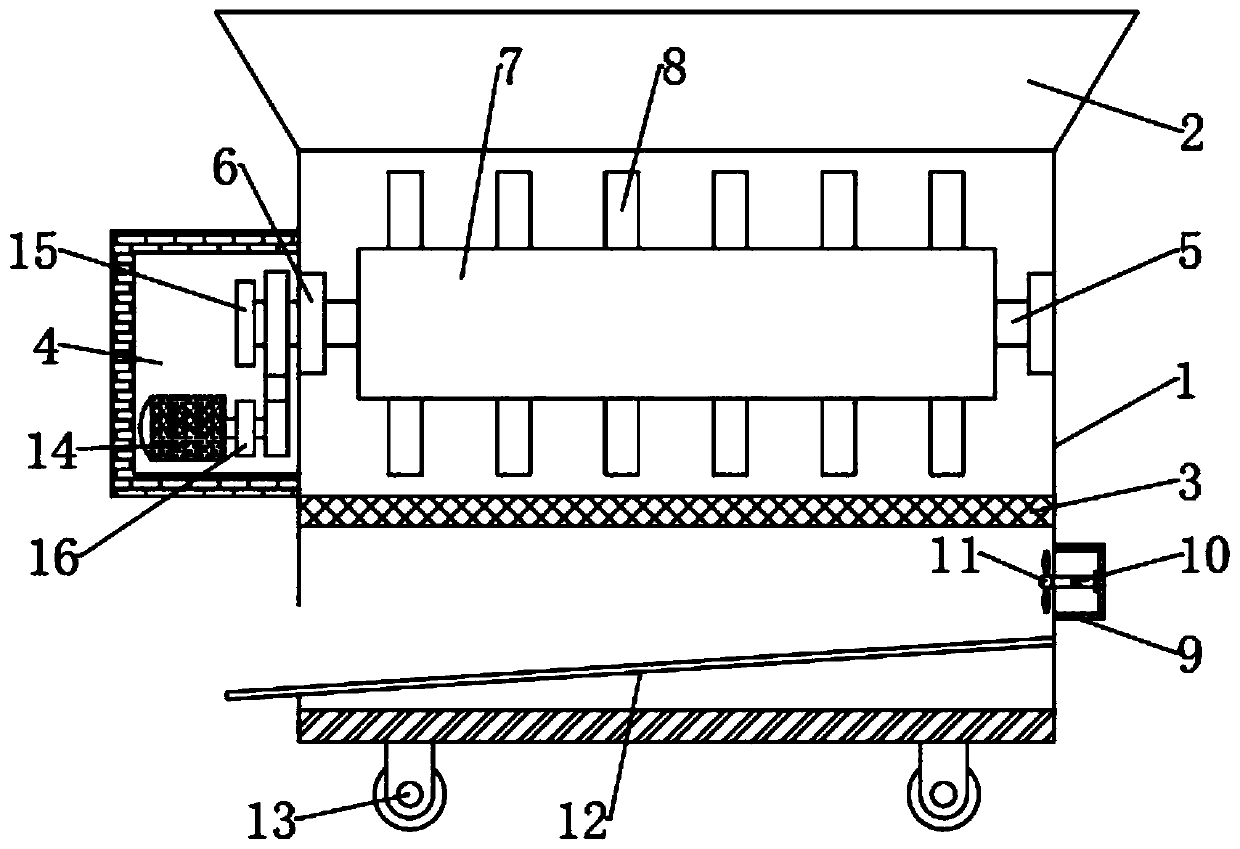

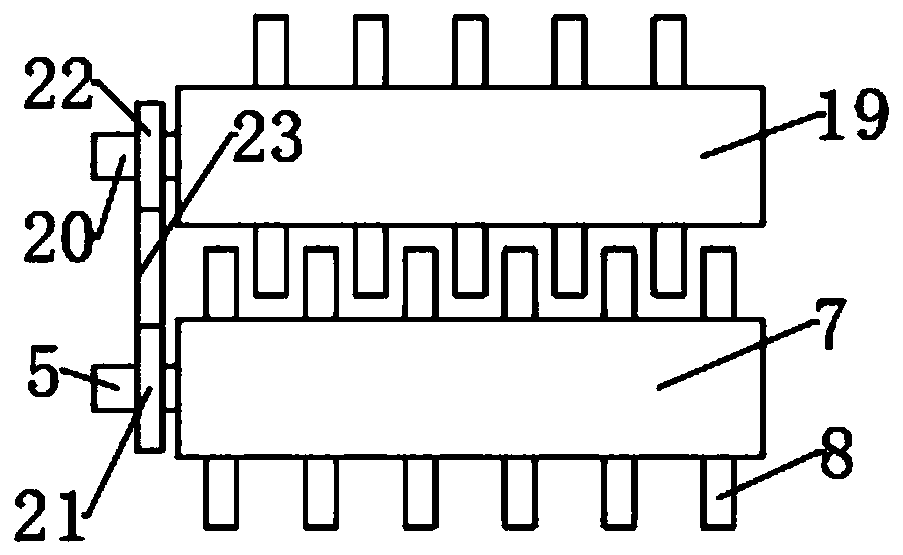

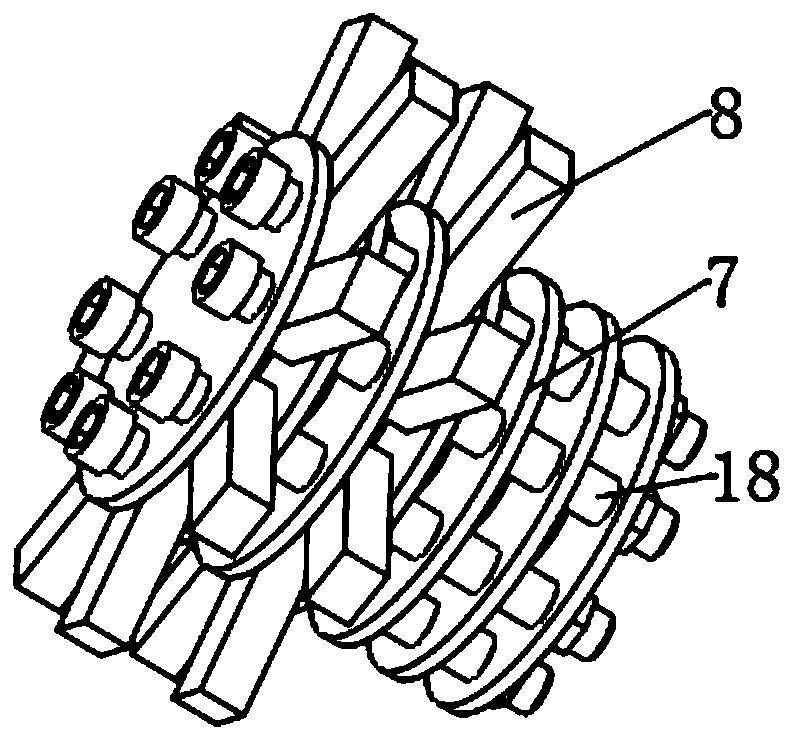

[0021] see Figure 1-4 , a waste paper crushing device for environmental protection, comprising a cavity 1, the top of the cavity 1 is provided with a feeding bin 2 with an opening outward, which is convenient for putting in waste paper; the cavity 1 is provided with a crushing mechanism, and the crushing The specific structure of the mechanism is not limited. Preferably, in this embodiment, the pulverizing mechanism includes a driving shaft 5, the driving shaft 5 is installed on the inside of the cavity 1 through a fixed bearing 6, and a knife seat 7 is arranged on the driving shaft 5. , a plurality of mounting grooves are equidistantly arranged on the knife seat 7, and a plurality of mounting holes are evenly distributed on the knife seat 7, and a blade 8 is installed in the mounting groove of the knife 7, and the blade 8 and the knife seat 7 are connected by connecting bolts 18 assembly connection; blades 8 with different numbers and different distances can be selectively a...

Embodiment 2

[0031] In embodiment 1, it is not convenient for the operator to observe the operation status of the crushing mechanism when the crushing device is in operation, and the paper sheets may not be processed in time when they are piled up on the discharge plate 12; Based on the improvement, the improvements are as follows: an observation window is set on one side of the cavity 1, which is convenient for the operator to check the operation of the crushing mechanism, and when the paper sheets are piled up on the discharge plate 12, the fan 11 can be turned on in time Processing is carried out to ensure the stable operation of the crushing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com