High-pressure steam thermal desorption repair system

A high-pressure steam and repair system technology, applied in the field of pollution repair systems, can solve the problems of difficult construction of reaction wall projects and no engineering cases, and achieve the effects of improving energy utilization efficiency, reducing construction difficulty, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

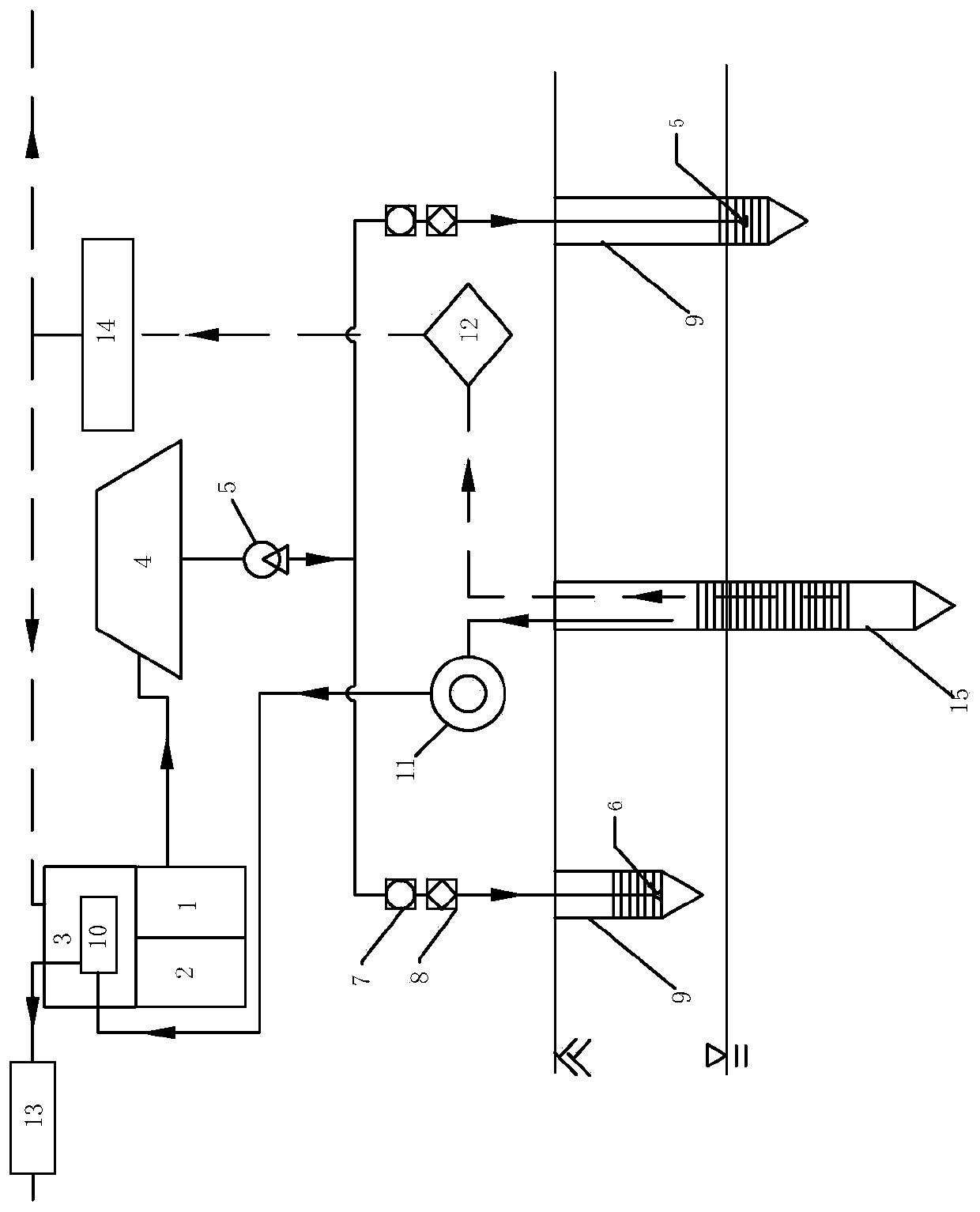

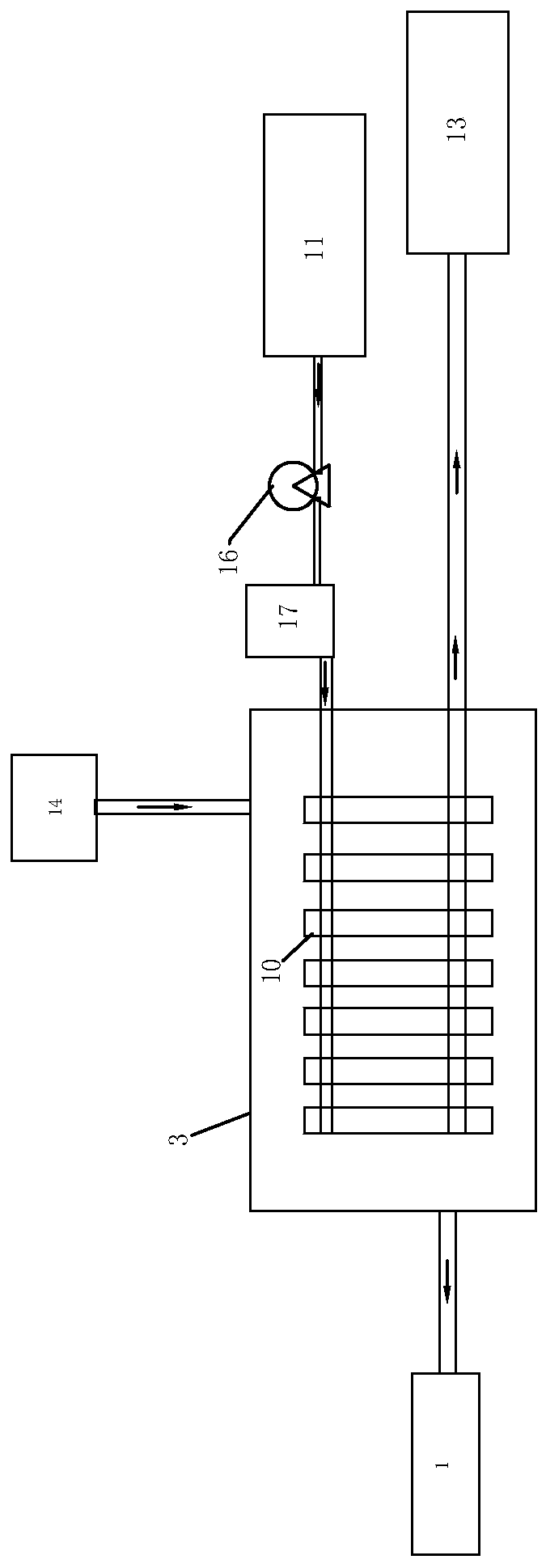

[0027] Such as figure 1 , figure 2 As shown, the present invention provides a high-pressure steam thermal desorption repair system, including an injection system and an extraction system, wherein:

[0028] The injection system includes a steam generator 1, a heat source 2, a preheating box 3, a high-pressure steam container 4, a high-pressure air pump 5, a steam nozzle 6, a pressure gauge 7, a flow meter 8 and an injection well 9, wherein:

[0029] The steam generator 1 can utilize the heat provided by the heat source 2 to heat water into high-pressure steam;

[0030] The heat source 2 can use fuel, electricity or other energy sources to provide heat for the steam generator 1;

[0031] The preheating box 3 is located upstream of the steam generator 1 and has a built-in heat exchanger 10, which can preheat the water entering the steam generator 1 through heat exchange;

[0032] The high-pressure steam container 4 is located downstream of the steam generator 1 and is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com