Riveting process of u-shaped beam

A crossbeam and U-shaped technology, which is applied in the field of U-shaped crossbeam riveting technology, can solve the problems of time-consuming and laborious detection, falling out of the crossbeam 2, and limited reduction of the opening width of the groove 11, so as to improve the assembly quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with the specific embodiments.

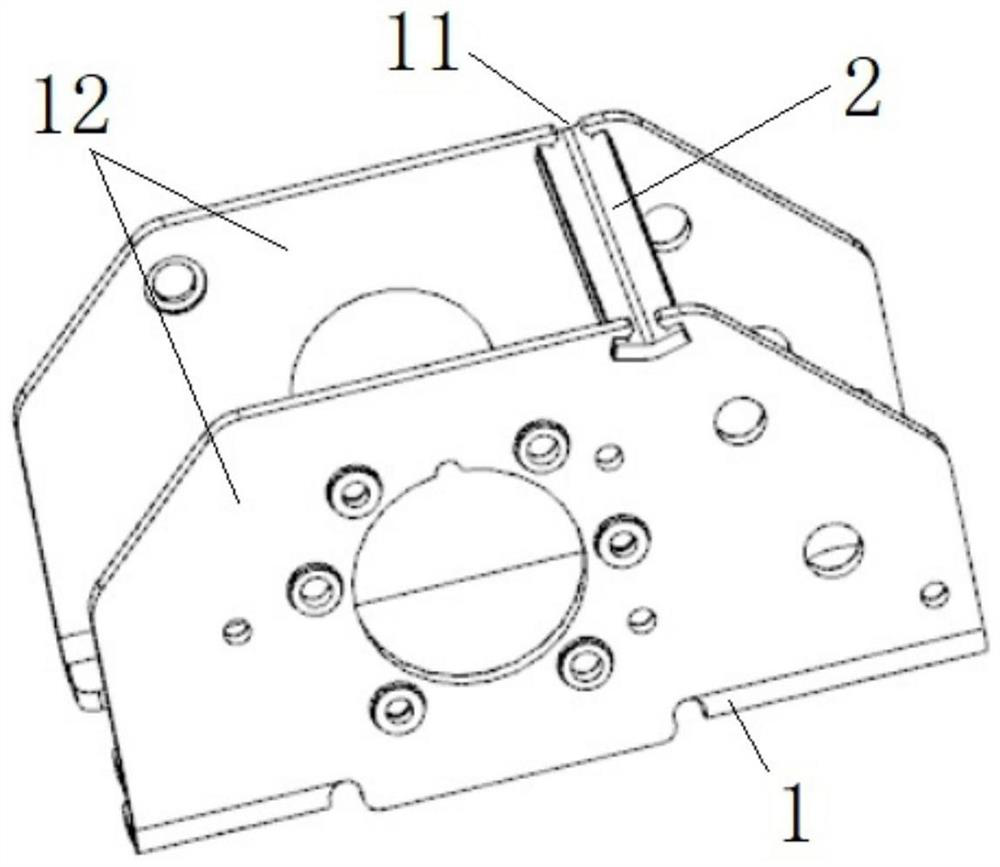

[0026] like image 3 with Figure 4 As shown, a U-shaped beam riveting process of the present invention includes:

[0027] 1 tape strip strip: For the metal tape, the contour is diced without completely cut, and two recess 11 used to assemble the beam 2;

[0028] 2 Material U-bending: U-shaped bent is performed as a reference feed surface as a reference surface, forming two facing surface 12 of each other;

[0029] 3U-shaped parts falling: cutting the main body of the U-shaped parts 1 from the material tape;

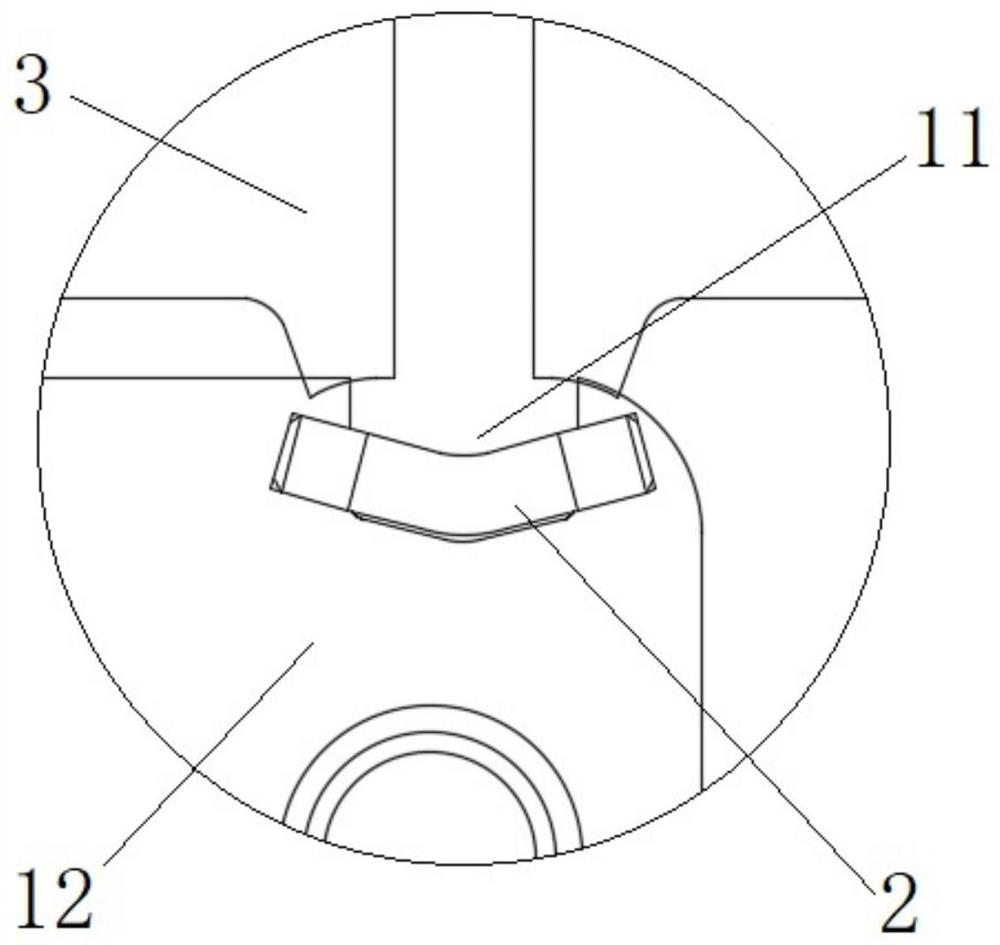

[0030] 4 Beam assembly: the bayonet card on both ends of the beam 2 into the groove 11;

[0031] 5 riveting: The U-shaped member 1 groove 11 containing the beam 2 is placed upward in the riveting machine, and the inlet edge of the groove 11 is pressed and deformed, and the beam 2 is stuck;

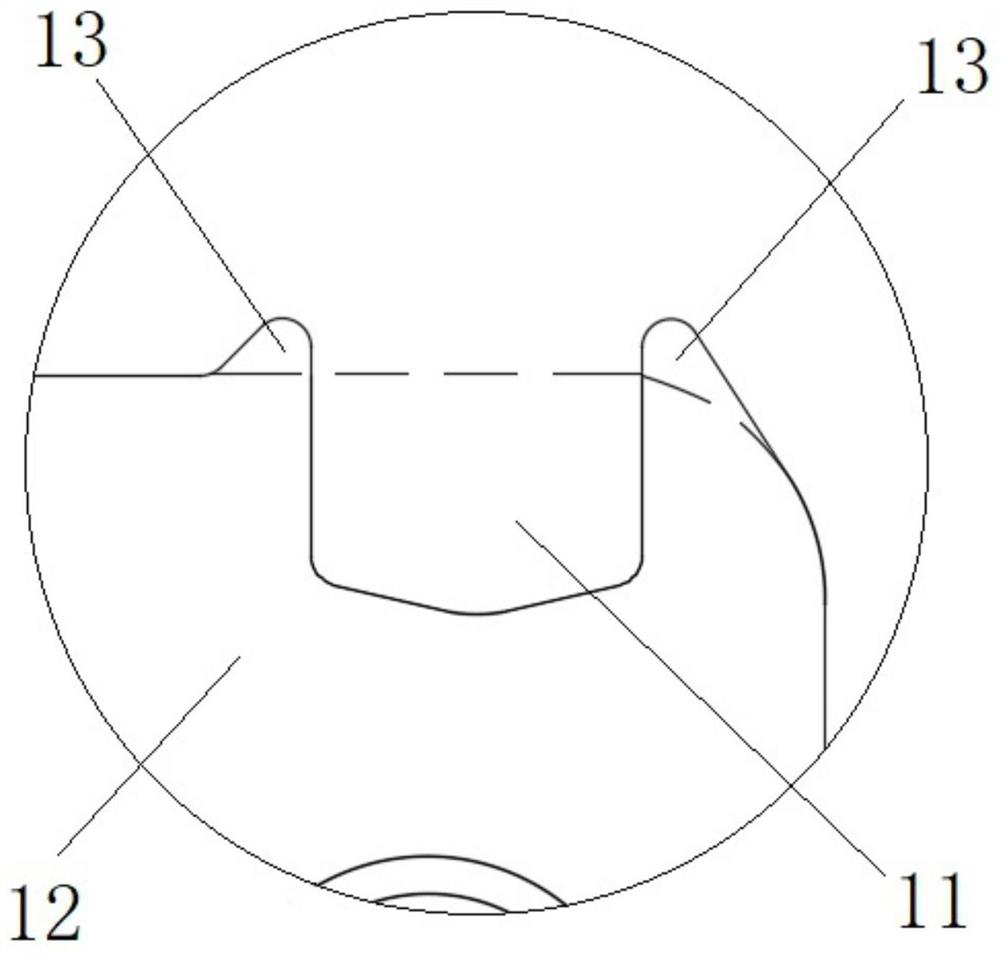

[0032] The shape of the tape strip section increases the projection portion 13 on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com