Alloy precise machining equipment capable of actively verifying product and working method thereof

A precision processing and product technology, applied in the direction of metal processing equipment, metal processing, metal processing machinery parts, etc., can solve the problems of automatic loading and unloading, low degree of automation, futile processing actions, etc., to reduce costs and energy consumption , Reduce labor demand and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

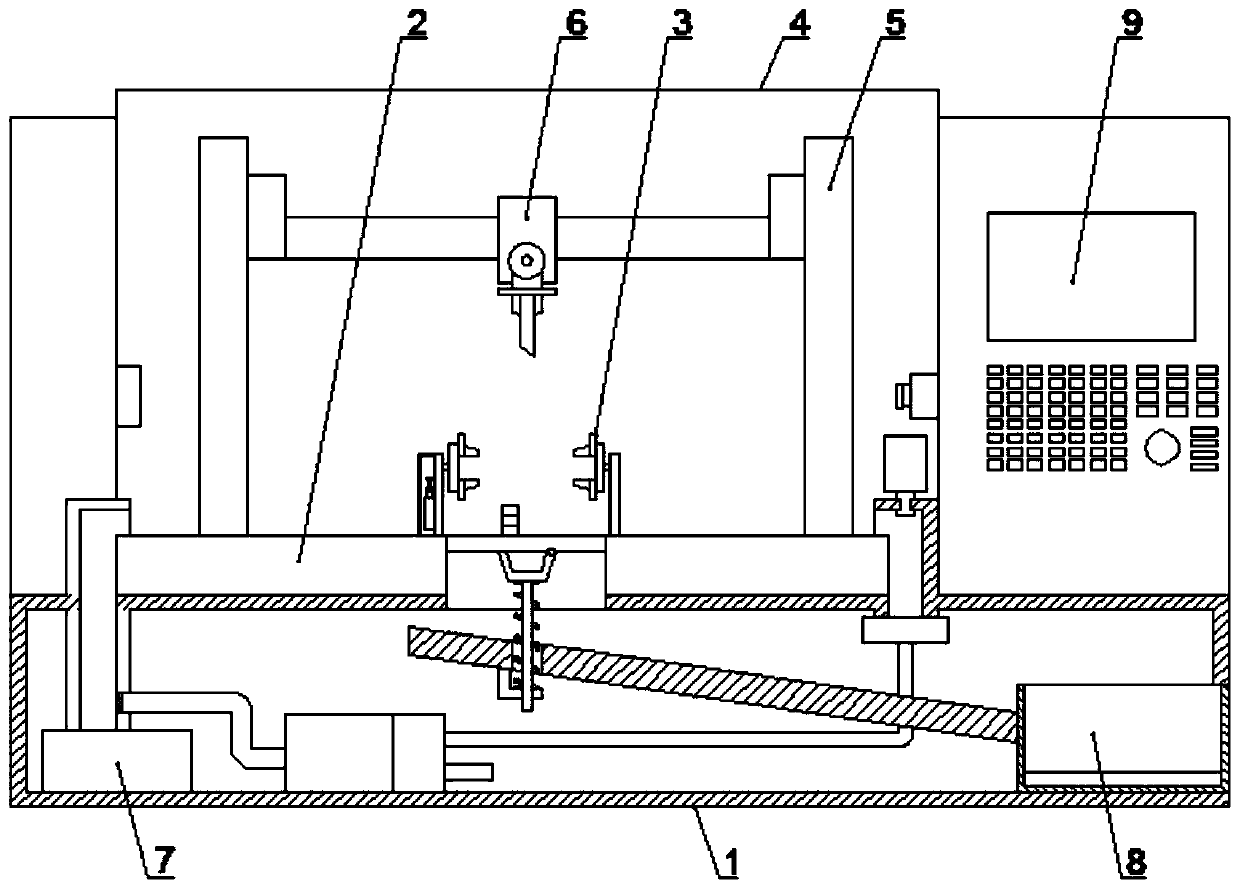

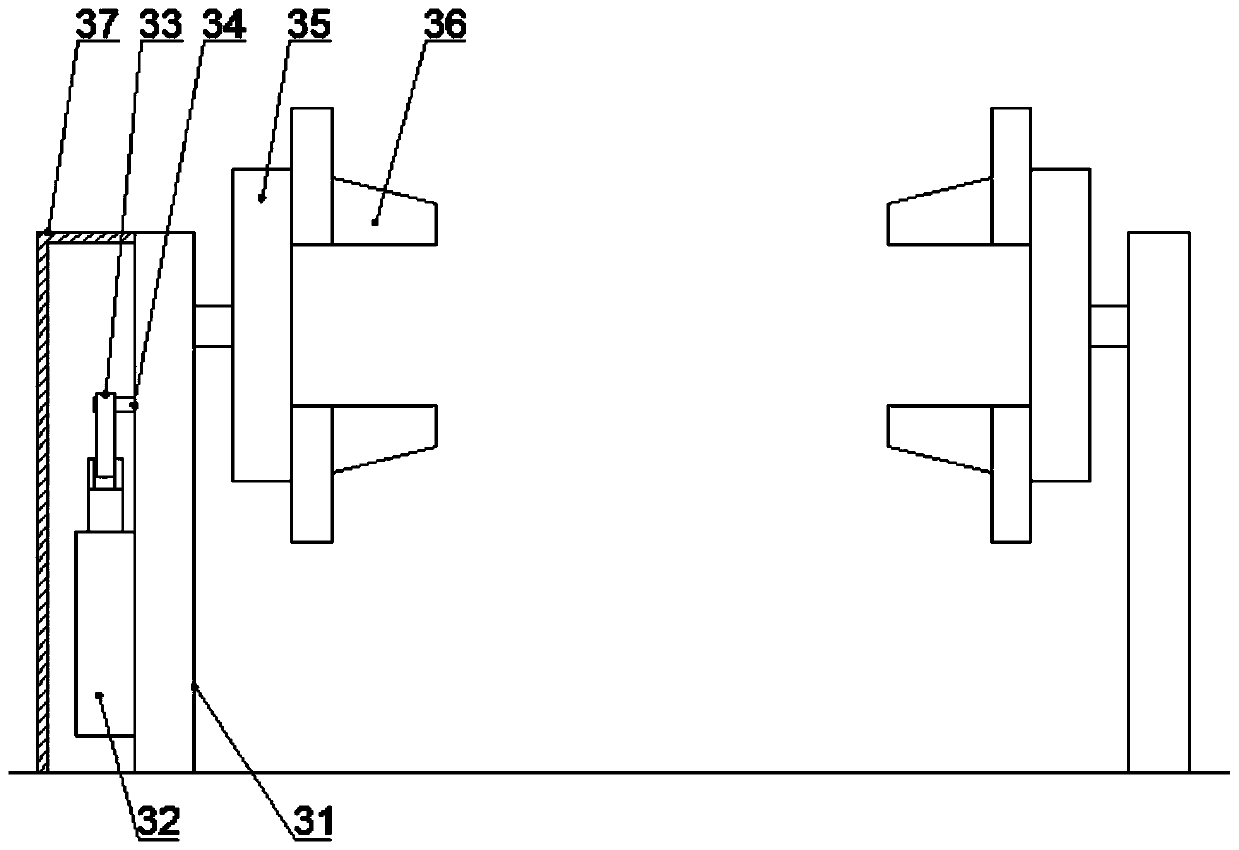

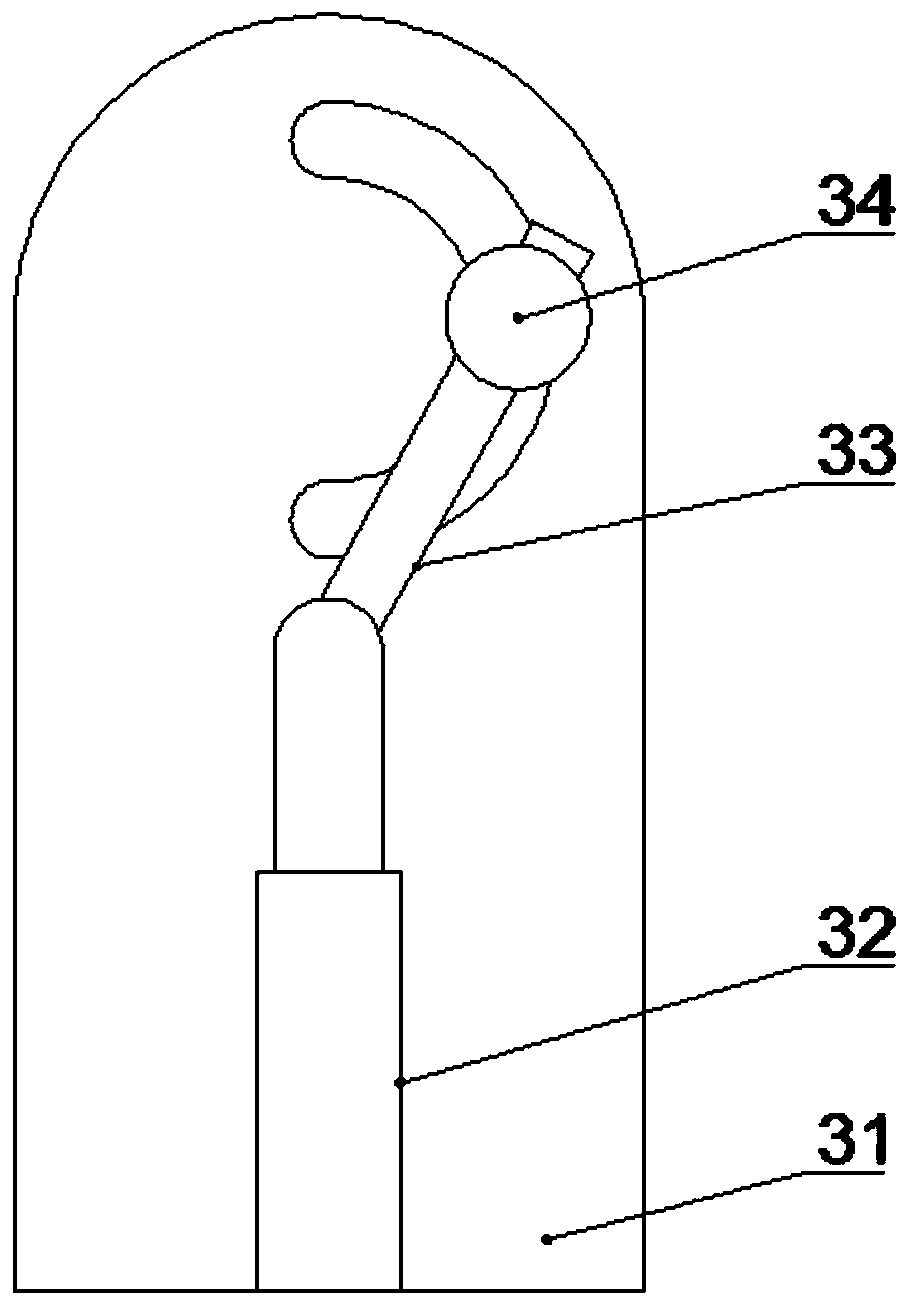

[0043] like Figure 1-9 The alloy precision processing equipment that actively verifies products is shown, including: base 1, working platform 2, fixture 3, protective cabin 4, multi-axis moving mechanism 5, working knife 6, air blowing mechanism 7 and loading and unloading mechanism 8 , the top of the base 1 is provided with a working platform 2, the center of the working platform 2 is provided with a clamp 3, and the outer side of the working platform 2 is provided with a protective cabin 4, and the protective cabin 4 covers the working platform 2. One side of the platform 2 is provided with a multi-axis moving mechanism 5, the rudder shaft moving mechanism 5 penetrates into the base 1, the rudder shaft moving mechanism 5 is arranged in the protective cabin 4, and the rudder shaft moving mechanism 5 is provided with Working knife 6, described working knife 6 is arranged on the top of working platform 2, and described working platform 2 side is provided with blowing mechanism...

Embodiment 2

[0055] like Figure 1-3 The alloy precision processing equipment that actively verifies products is shown, including: base 1, working platform 2, fixture 3, protective cabin 4, multi-axis moving mechanism 5, working knife 6, air blowing mechanism 7 and loading and unloading mechanism 8 , the top of the base 1 is provided with a working platform 2, the center of the working platform 2 is provided with a clamp 3, and the outer side of the working platform 2 is provided with a protective cabin 4, and the protective cabin 4 covers the working platform 2. One side of the platform 2 is provided with a multi-axis moving mechanism 5, the rudder shaft moving mechanism 5 penetrates into the base 1, the rudder shaft moving mechanism 5 is arranged in the protective cabin 4, and the rudder shaft moving mechanism 5 is provided with Working knife 6, described working knife 6 is arranged on the top of working platform 2, and described working platform 2 side is provided with blowing mechanism...

Embodiment 3

[0059] like figure 1 , 4 An alloy precision machining equipment for actively verifying products shown in and 5, including: a base 1, a working platform 2, a fixture 3, a protective cabin 4, a multi-axis moving mechanism 5, a working knife 6, an air blowing mechanism 7 and a loading and unloading mechanism. Mechanism 8, the top of the base 1 is provided with a working platform 2, the center of the working platform 2 is provided with a clamp 3, and the outer side of the working platform 2 is provided with a protective cabin 4, and the protective cabin 4 covers the working platform 2. One side of the working platform 2 is provided with a multi-axis moving mechanism 5, the rudder shaft moving mechanism 5 penetrates into the base 1, the rudder shaft moving mechanism 5 is arranged in the protective cabin 4, and the rudder shaft moving mechanism 5 A working knife 6 is provided, and the working knife 6 is arranged on the top of the working platform 2. A blowing mechanism 7 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com