Paper plastic package box side face pattern printing device

A pattern printing and packing box technology, which is applied in printing, printing machines, rotary printing machines, etc., to achieve the effects of improved recognition, high identification, and special composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

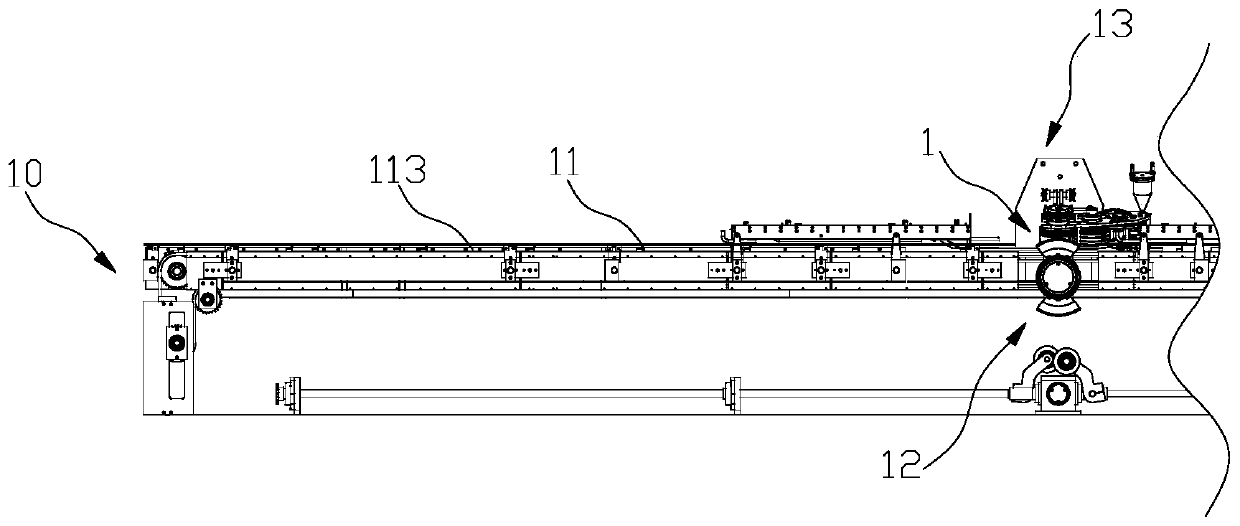

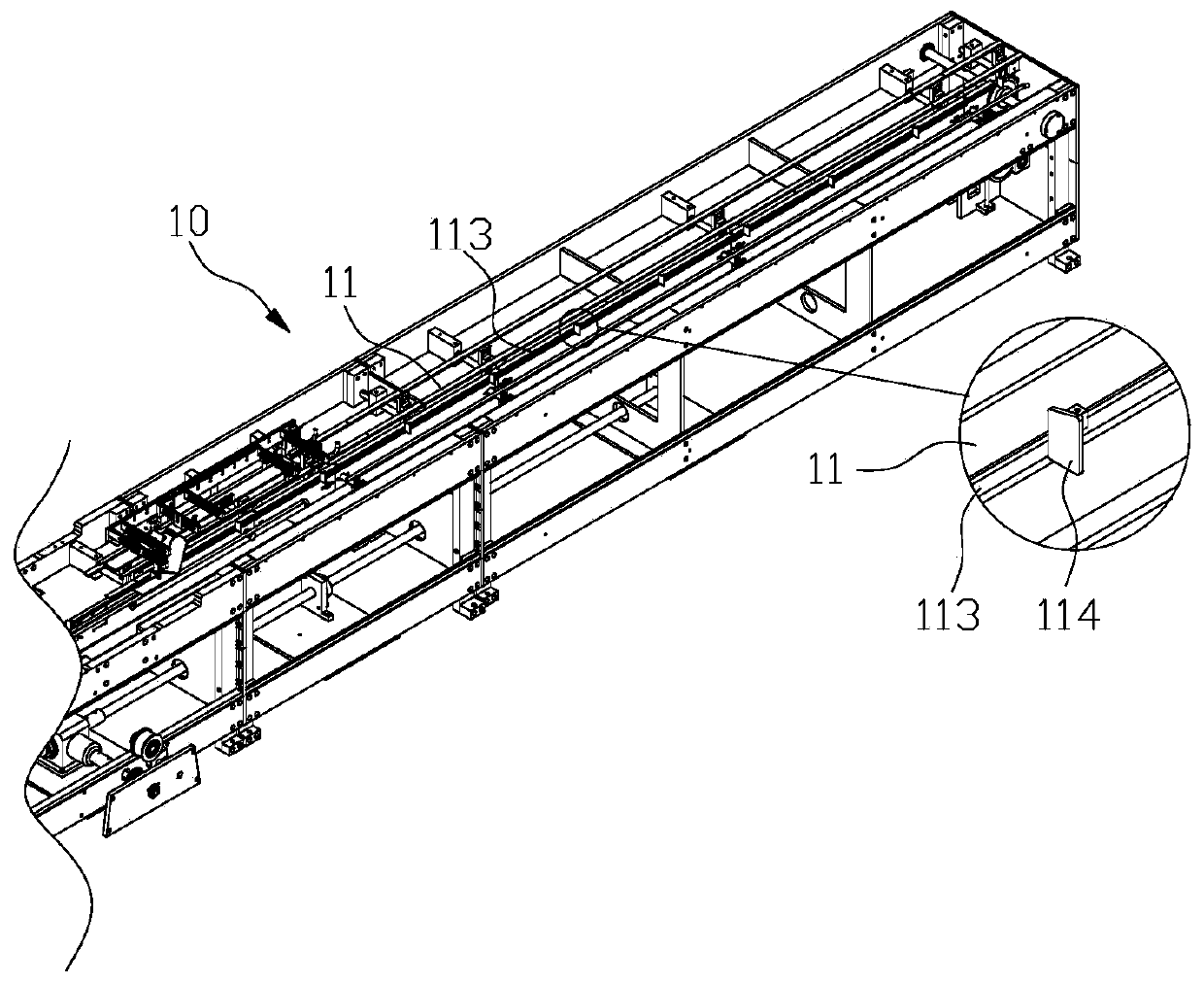

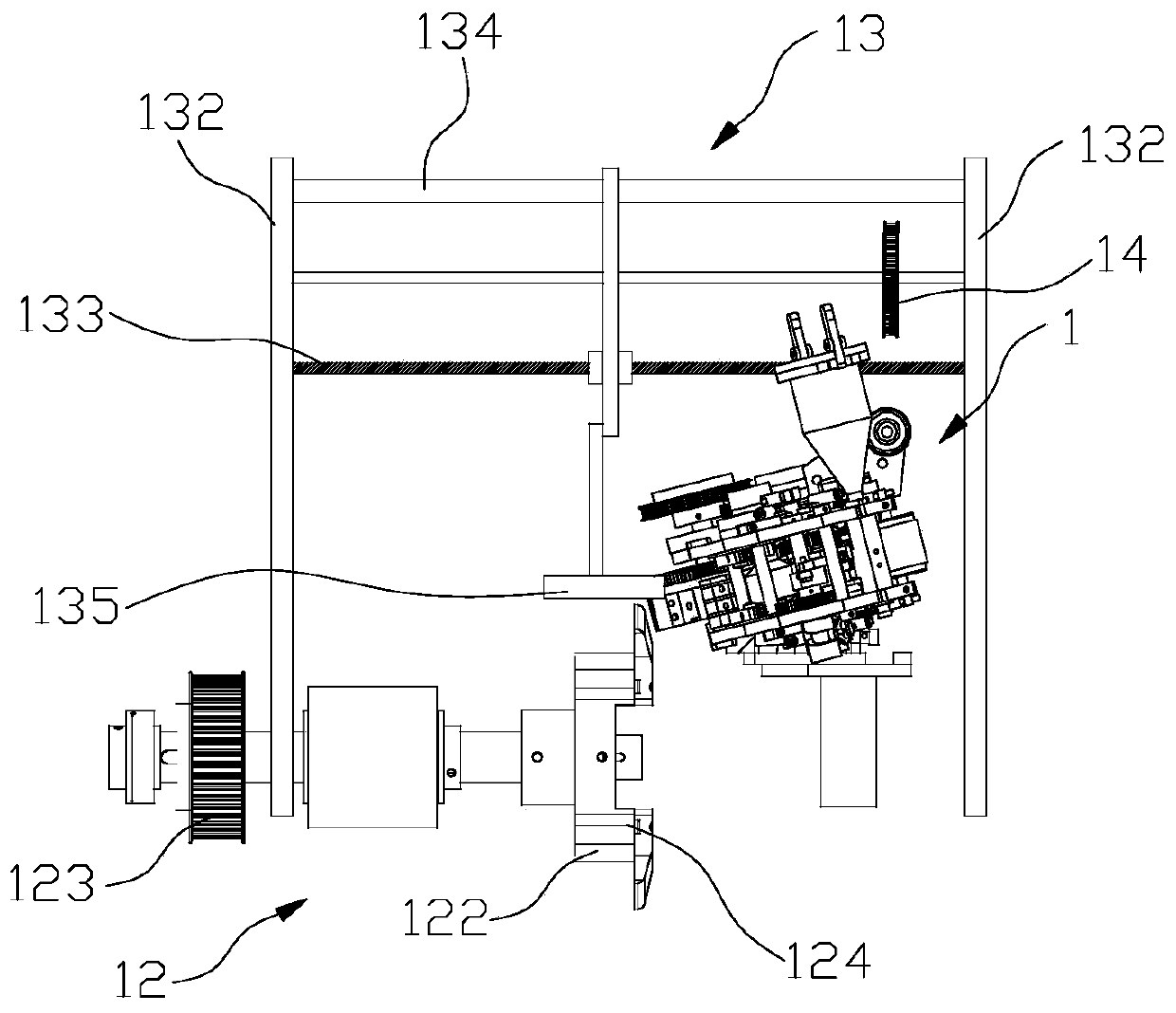

[0054] see Figure 1 to Figure 5 and Image 6 , The paper-plastic packaging box side pattern printing device of this embodiment includes a frame 10, a conveying device, a side pattern printing unit 1, a lower pressing device 12 and an upper pressing device 13; the conveying device, the side pattern printing unit 1, the lower The pressing device 12 and the upper pressing device 13 are arranged on the frame 10; the conveying device includes a guide rail 11 and a pushing mechanism, and the pushing mechanism is used to move the paper-plastic packaging box along the guide rail 11 to the side The pattern printing unit 1 pushes; the lower pressing device 12 is arranged on the guide rail 11 corresponding to the side pattern printing unit 1, and is used to press against the inner side of the paper-plastic packaging box; the side pattern printing unit 1 is arranged on the guide rail 11, and the side pattern Printing unit 1 comprises ink supply mechanism 3 and printing assembly, and ink...

Embodiment 2

[0108] see Figure 18 , this embodiment is an improved solution of the first embodiment, and the difference from the first embodiment is that there are two side pattern printing units 1 .

[0109] In this embodiment, there are two side pattern printing units 1 , and the two side pattern printing units 1 are correspondingly arranged on both sides of the guide rail 11 .

[0110] By setting side pattern printing units 1 on both sides of the guide rail 11, the two outer sides of the paper-plastic packaging box pushed to the side pattern printing unit 1 along the guide rail 11 can be printed simultaneously, thereby meeting different printing requirements , while improving the efficiency of printing paper-plastic packaging boxes. In addition, since the lower pressing device 12 corresponds to the side pattern printing unit 1, the two side pattern printing units 1 can share the same lower pressing device 12 to support the paper-plastic packaging box during printing. Inner side, there...

Embodiment 3

[0115] see Figure 19 to Figure 21 , This embodiment is an improved solution of Embodiment 1 or Embodiment 2, and the difference from Embodiment 1 or Embodiment 2 lies in the structure of the side pattern printing unit 1 .

[0116] The printing assembly includes two printing plate rollers 4 and printing rollers 5, and the two printing plate rollers 4 and printing rollers 5 are axially rotatably arranged on the mounting base 2; the two printing plate rollers 4 are correspondingly arranged on both sides of the printing roller 5 .

[0117] Since there are two printing plate rollers 4, there are two corresponding first distance adjustment mechanisms, and the first push rods 641 of the two first distance adjustment mechanisms are connected by the first elastic member 63, that is, the first One end of an elastic member 63 is connected to the first push rod 641 on the left side of the printing roller 5, and the other end of the first elastic member 63 is connected to the first push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com