Spray head based on ink-jet printer

A technology for printers and nozzles, applied in printing and other directions, can solve the problems of printer life, affecting printing quality, and water backflow, etc., and achieve the effects of easy assembly and maintenance, good printing effect, and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below according to the drawings and embodiments.

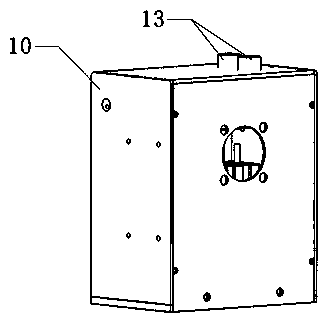

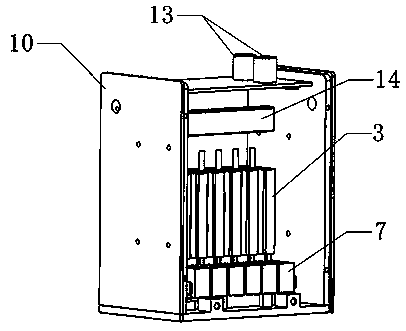

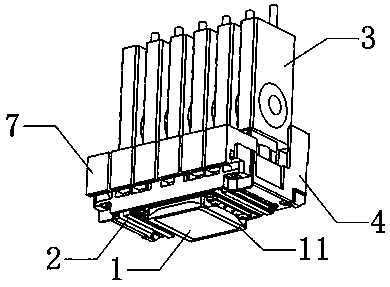

[0030] Such as Figure 1-7 Shown, a kind of nozzle based on jet code printer comprises nozzle panel 1 and ink bag 3, and described nozzle panel 1 and control panel 2 are bonded, and is fixed on the bottom surface of nozzle bracket 4; Along the bottom surface of described nozzle bracket 4 A number of ink inlet through holes 15 are provided, and a baffle 5 is arranged between each adjacent ink inlet through hole 15 to form an ink inlet compartment 6, and a needle tube device for guiding ink is installed in the ink inlet compartment 6 7. The ink bag 3 supplies ink to the nozzle 8 on the nozzle panel 1 along the ink guiding needle 12 on the needle device 7 .

[0031] Specifically, the connection mode of this device is that the ink bag 3 is used to transfer the ink inside the cavity to the nozzle panel 1 through the ink guide needle tube 12 on the needle tube device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com