Groove sealing plate and unloading plate joint structure of welding type groove-shaped bulkhead

A technology of grooved bulkheads and unloading plates, which is applied in the direction of hull bulkheads, hull compartments, ships, etc., and can solve the problem that the welding quality of stress concentration points is not easy to be guaranteed, the welding quality is not easy to be guaranteed, and the number of welds increases, etc. problems, to achieve the effect of increasing the life of the hull, reducing stress, and controlling welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

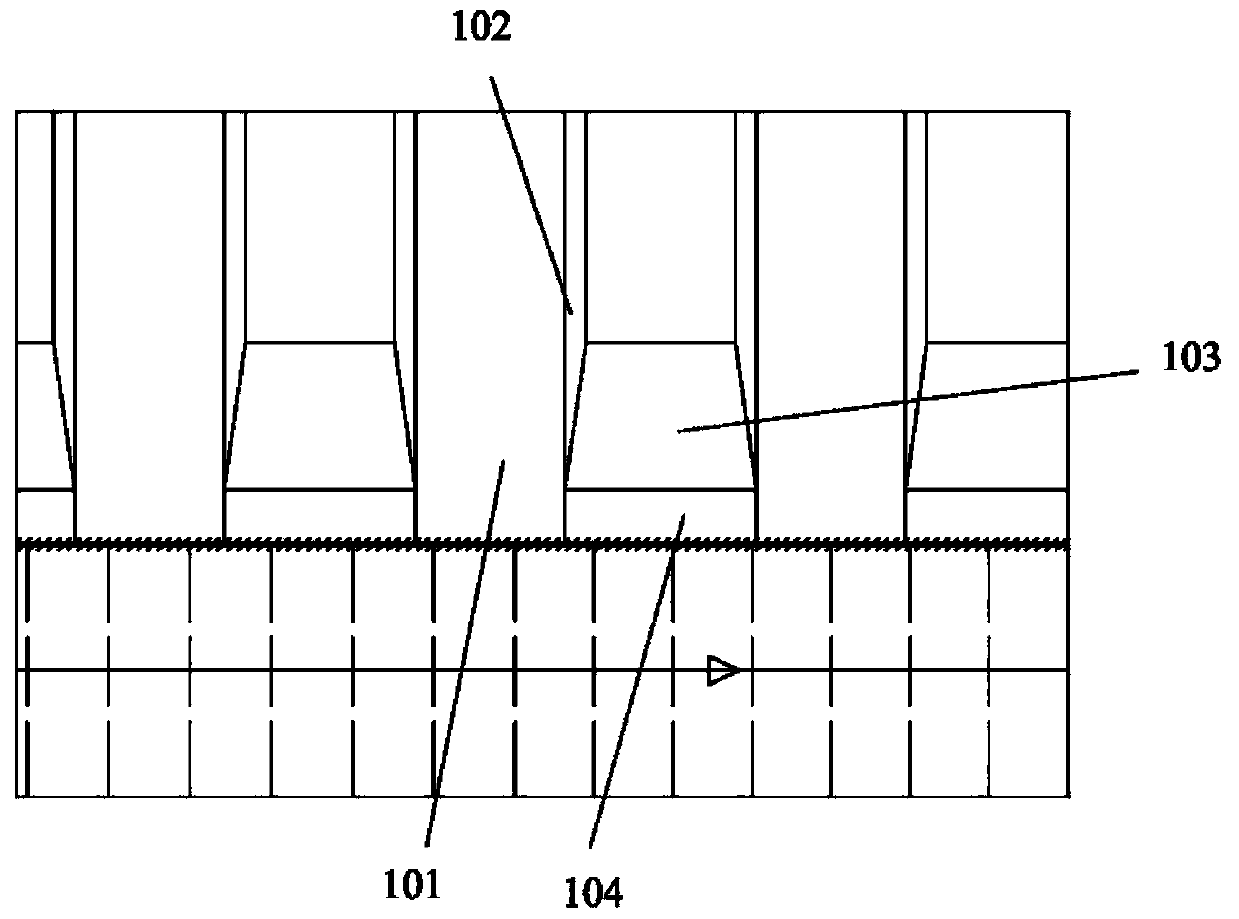

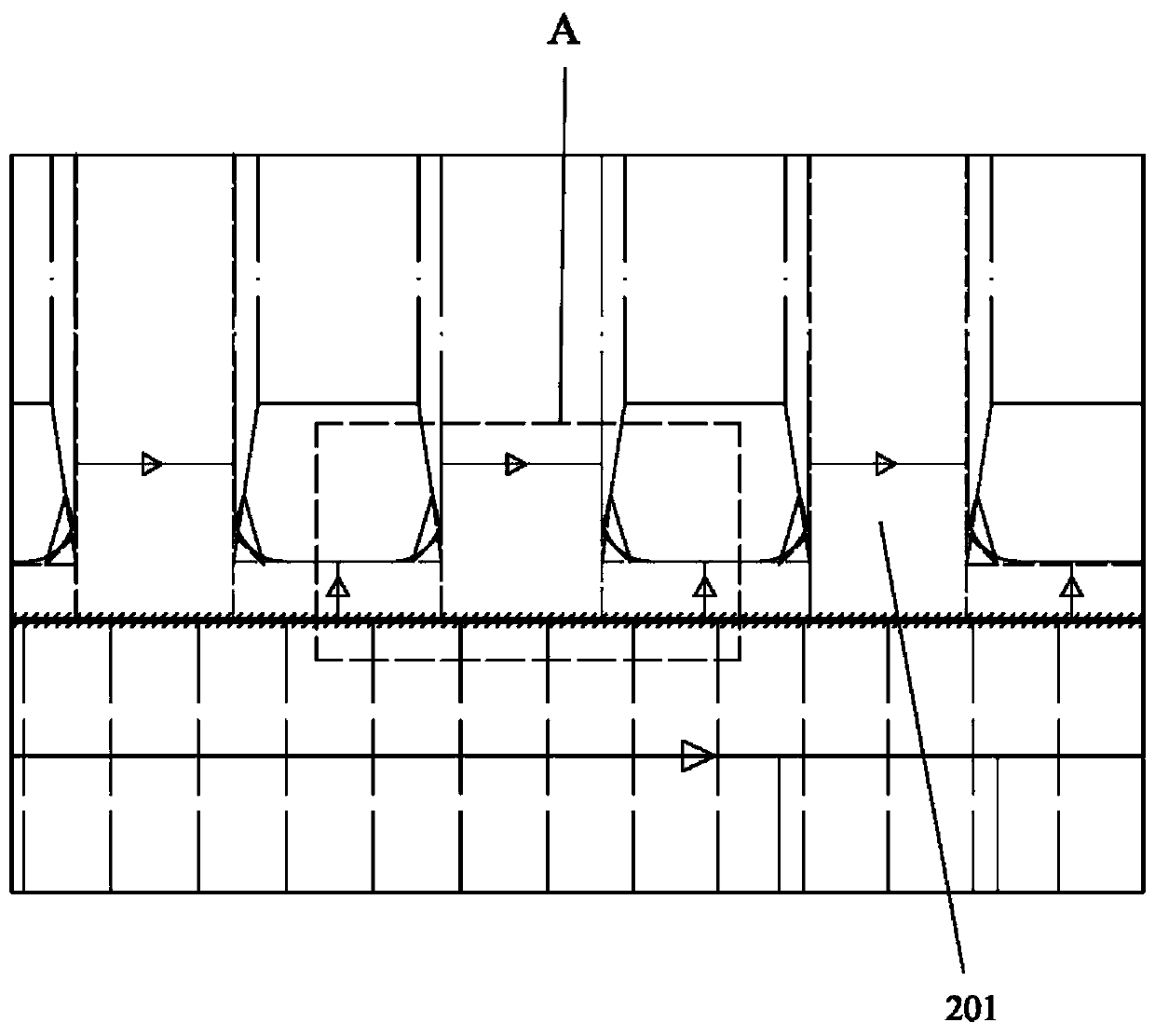

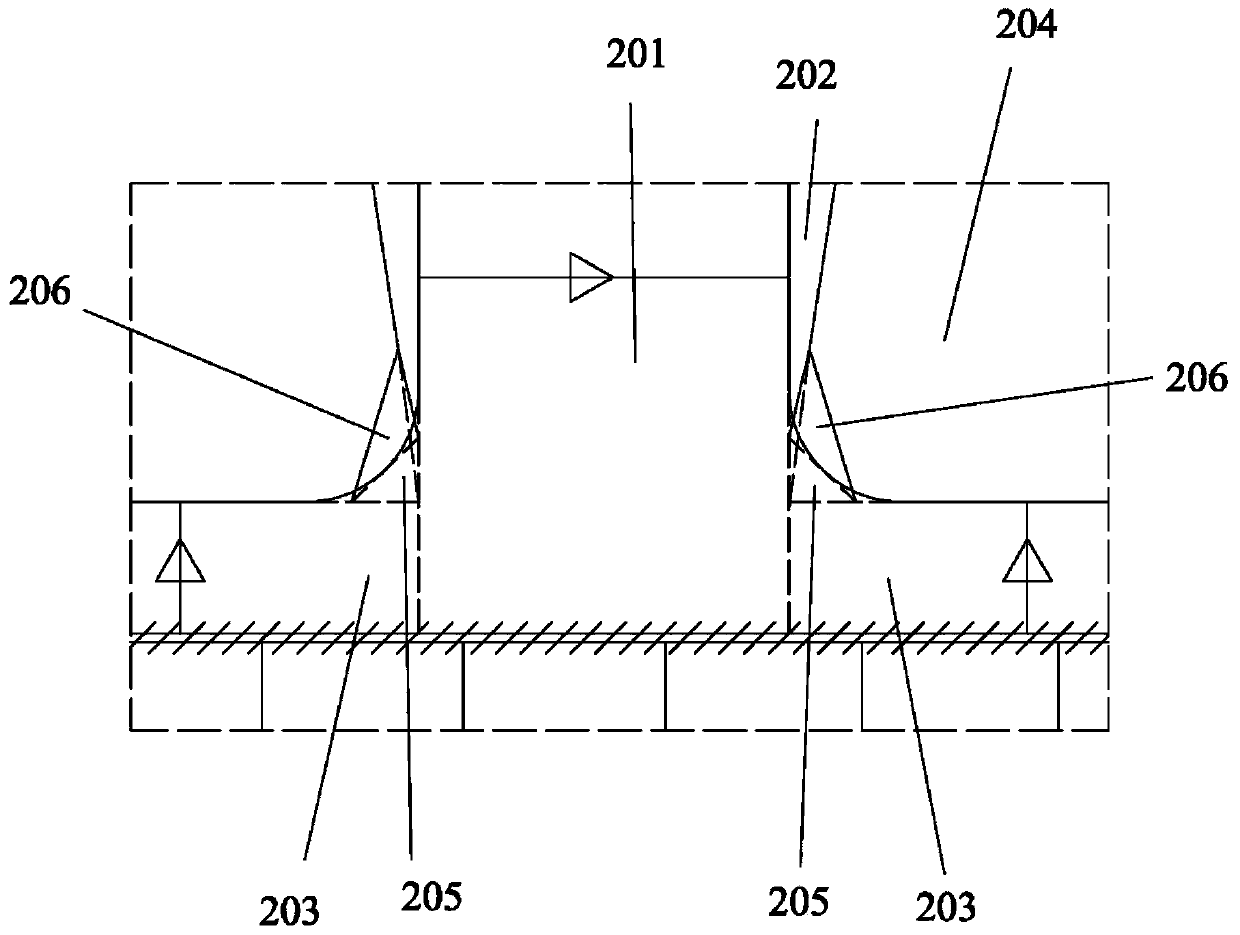

[0024] Such as figure 2 , image 3 with Figure 4 As shown, a joint structure of a welded corrugated bulkhead and a shedding plate, which includes a channel panel 201, a channel web 202, a channel sealing plate 203 and a shedding plate 204, the channel panel 201 and the channel The strip web 202 is welded and connected, the groove sealing plate 203 is connected to the groove strip face plate 201 , and the unloading plate 204 is connected to the groove strip web 202 and the groove sealing plate 203 at the same time.

[0025] Both sides of the channel panel 201 are respectively connected with a channel sealing plate 203, and each of the two channel sealing plates 203 is connected with a bracket 205. The two brackets 205 are respectively connected to both sides of the channel panel 201. The free edge of is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com