Water surface jumping gliding robot

A gliding robot and main body technology, which is applied in the direction of glider, seaplane, aircraft, etc., can solve the problems of impact during the fall process, unstable jumping posture, and single motion form, so as to reduce impact, improve motion flexibility, and expand motion space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

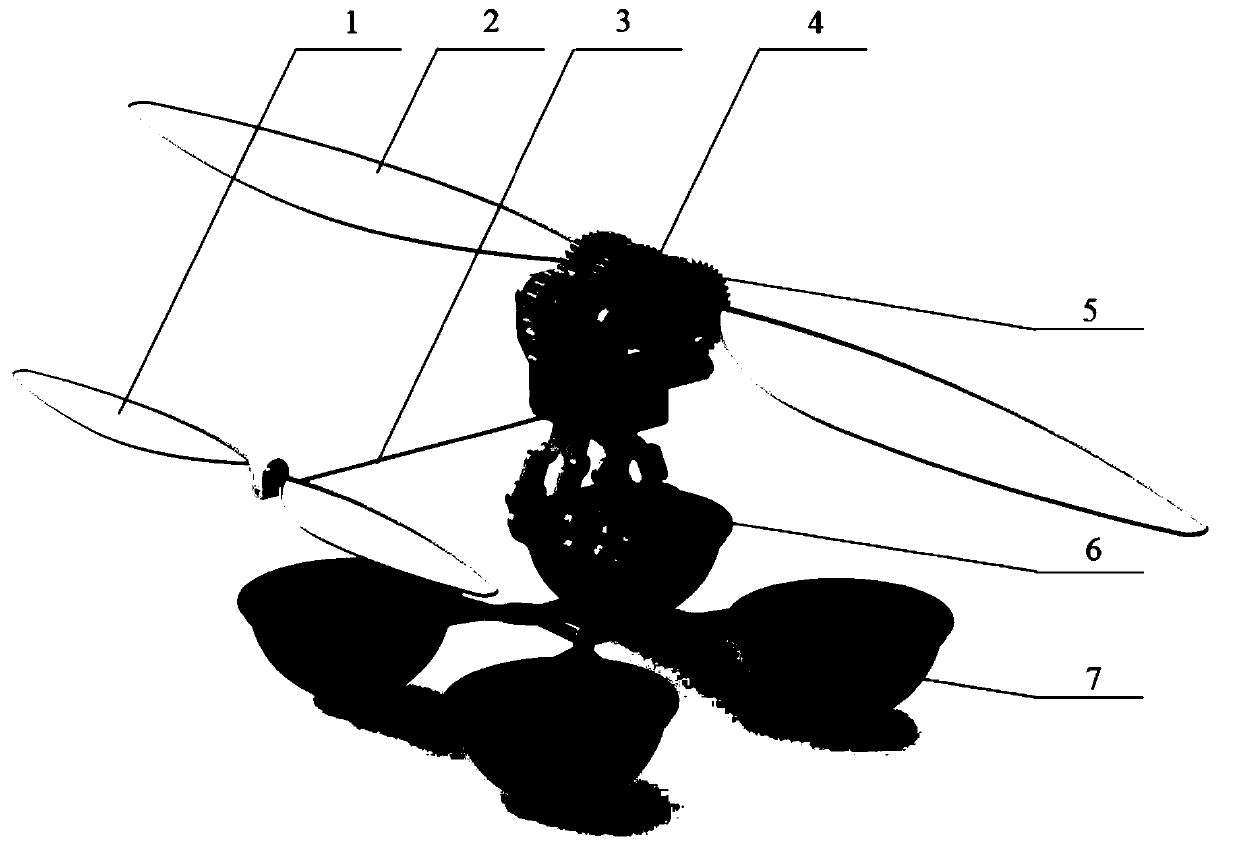

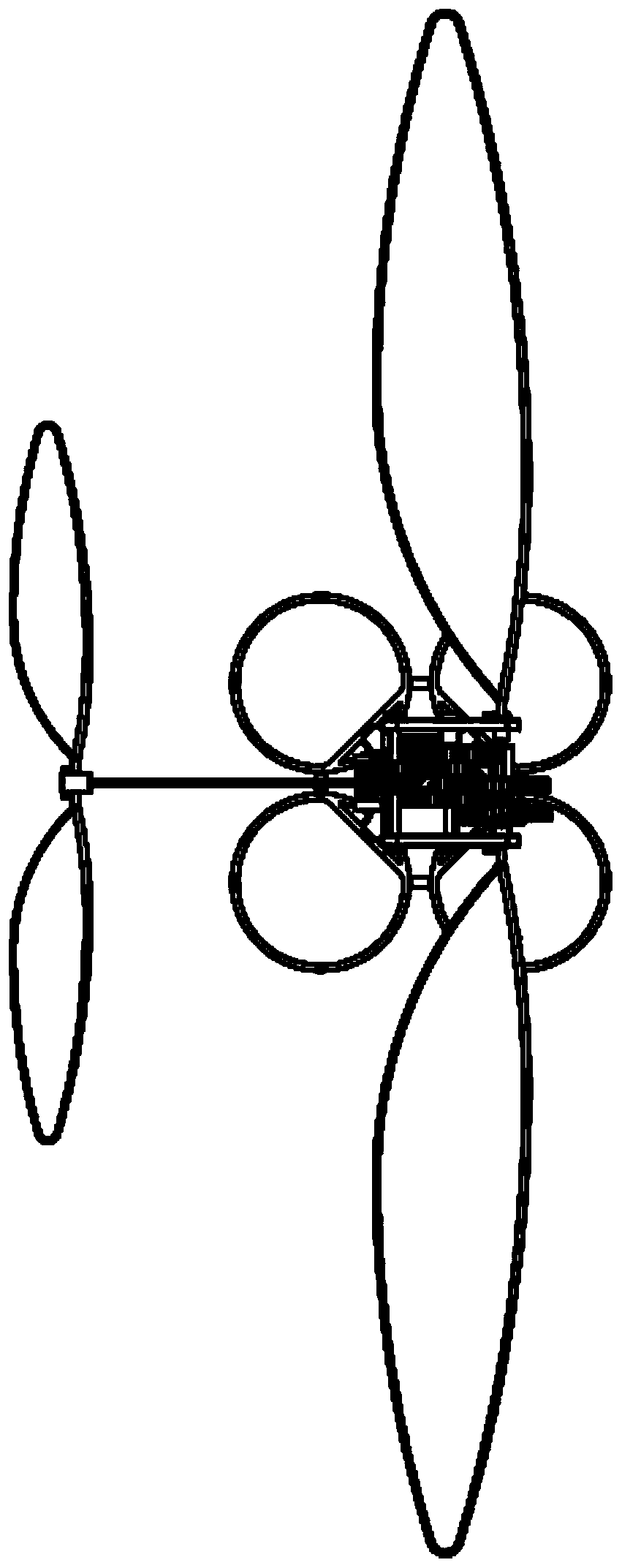

[0035] Specific implementation mode one: as Figure 1-9 As shown, a water surface jumping gliding robot described in this embodiment includes a main body support frame 4, an empennage 1, a gliding wing 2, a tail support 3, a connecting rod bounce mechanism 6, a water surface support system 7 and a drive system 5; The main body support frame 4 is located at the top of the robot, and the hang glider 2 is symmetrically installed on both sides of the main body support frame 4 through the front end bearing hole of the main body support frame 4, and the tail support 3 is installed on the tail support installation hole at the rear of the main body support frame 4 , the empennage 1 is installed symmetrically on both sides of the tail support 3, the connecting rod jumping mechanism 6 is symmetrically arranged directly below the main body support frame 4, and the water surface support system 7 is installed directly below the connecting rod jumping mechanism 6, the The drive system 5 is ...

specific Embodiment approach 2

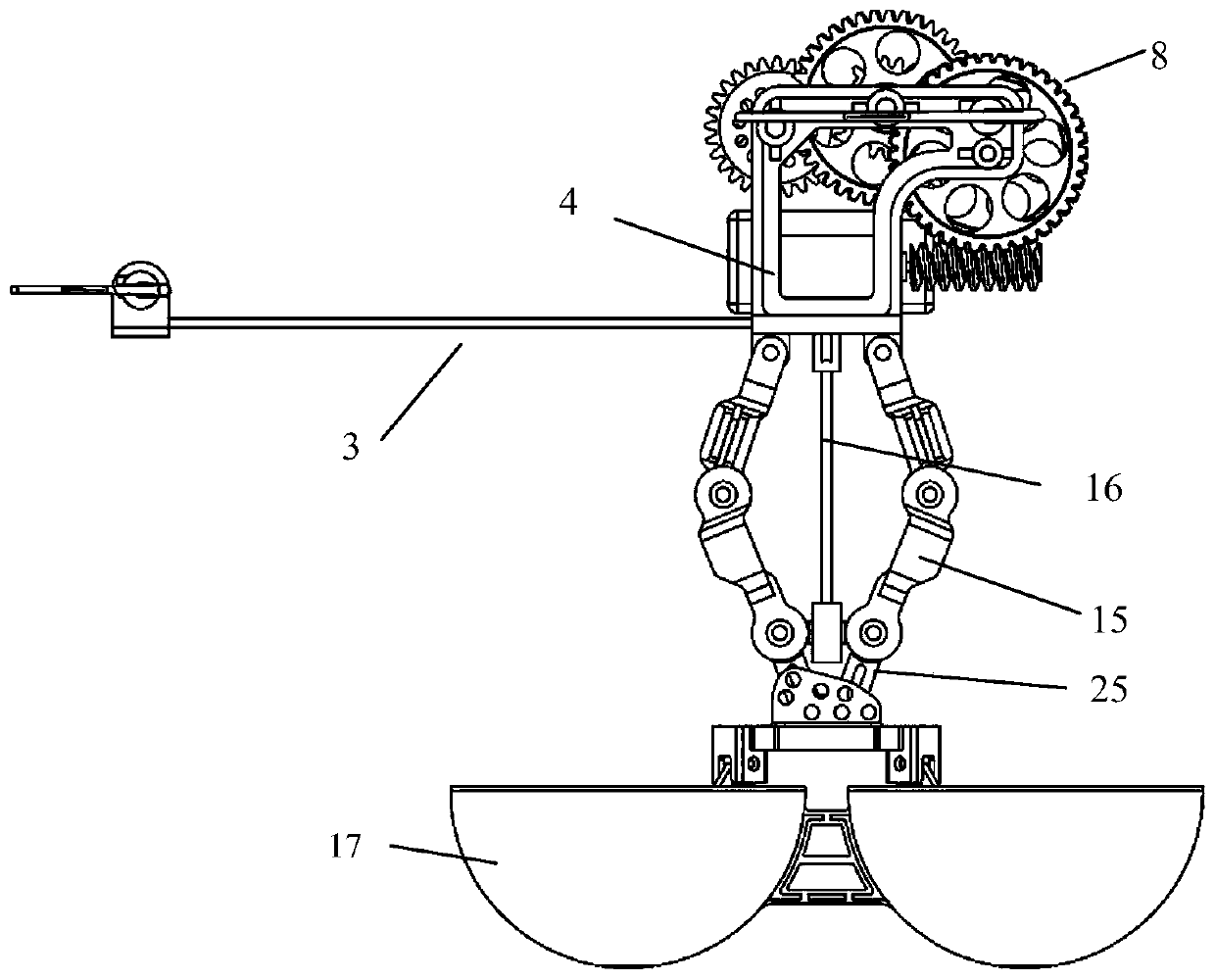

[0036] Specific implementation mode two: as Figure 1-7 As shown, the link bounce mechanism 6 in this embodiment is a symmetrical structure, which includes a multi-link suspension frame and an energy storage element installed on the multi-link suspension frame. The energy storage element includes a tension spring and a torsion spring. The driving system 5 stores energy on the connecting rod bouncing mechanism through the transmission mechanism thereon, and cuts off the power from the driving system 5 through the incomplete gear mechanism to complete the release of the connecting rod bouncing mechanism, thereby driving the water support system 7 to complete the jumping action. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0037] Specific implementation mode three: as Figure 1-7 As shown, the link bouncing mechanism 6 in this embodiment is a six-link bouncing mechanism comprising a multi-link suspension frame and an energy storage original; the multi-link suspension frame is a three-dimensional six-link suspension frame, which includes Two pairs of H-shaped rods 15, a V-shaped part and two guide rods 16, the energy storage element includes four torsion springs 13 and two tension springs 14, and the four lower ends of the pair of H-shaped rods 15 above part and the four upper ends of a pair of H-shaped rods 15 located below are hinged one by one to form four joints located in the middle of the six-link suspension frame, each joint is correspondingly equipped with a torsion spring 13, and one located above The respective upper ends of the H-shaped rods 15 are hinged one by one to the corresponding connecting holes on the main support frame 4, and the respective lower ends of a pair of H-shaped ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com